Stator core, motor, compressor and vehicle

A stator iron core and iron core technology, which is applied in the field of vehicles, can solve the problems of winding nozzle interference, affecting the performance of the motor, affecting the winding effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

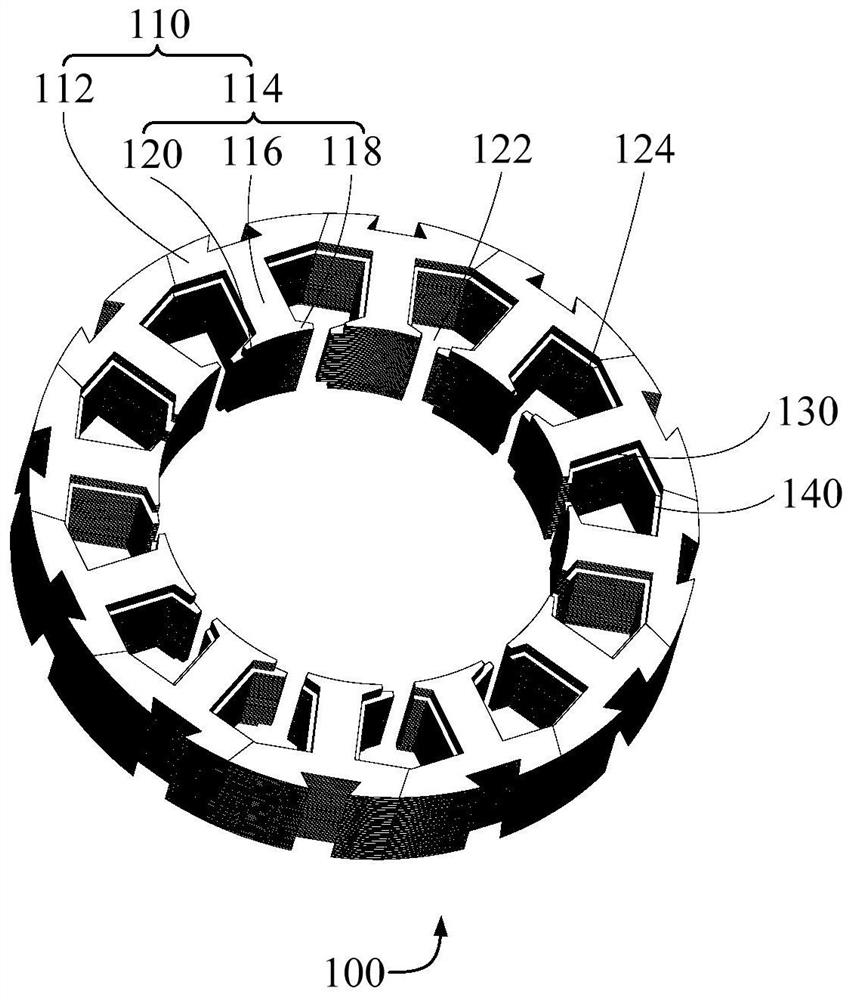

[0096] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 8 , Figure 11 and Figure 12 As shown, the embodiment of the first aspect of the present invention proposes a stator core 100, the stator core 100 includes a plurality of segmented iron cores 110, and the plurality of segmented iron cores 110 are connected end to end in turn around the axis of the stator core 100 , each segmented iron core 110 includes a plurality of stacked stamping sheets.

[0097] Each segmented iron core 110 includes a connected stator yoke 112 and stator teeth 114, the stator teeth 114 are located between the axes of the stator yoke 112 and the stator iron core 100, and the stator yokes 112 of any two adjacent segmented iron cores 110 The stator slot 122 is surrounded by the stator teeth 114 .

[0098] The wall surface of the stator yoke 112 facing the axis of the stator core 100 is a split surface 124 ; along the circumferential direction of the stator core 100 , at l...

Embodiment 2

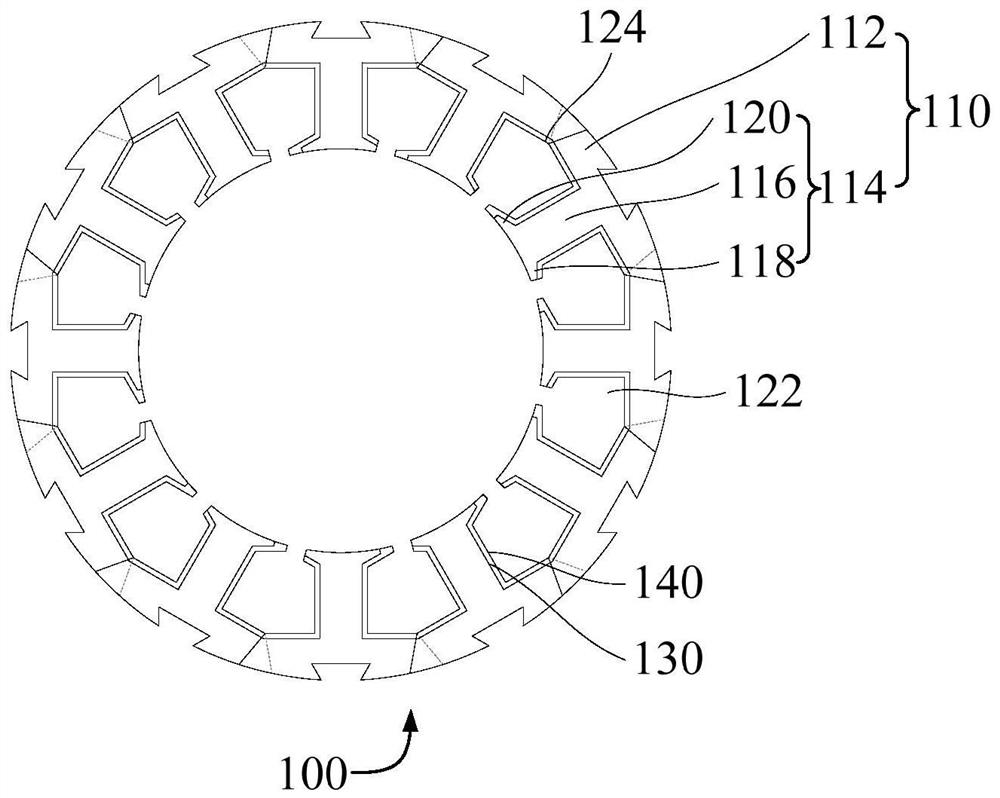

[0107] like Figure 1 to Figure 5 , Figure 8 , Figure 11 and Figure 12 As shown, on the basis of Embodiment 1, Embodiment 2 provides a stator core 100, the stator core 100 includes a plurality of segmented iron cores 110, and the plurality of segmented iron cores 110 surround the axis of the stator core 100 Connected end to end in sequence, each segmented iron core 110 includes a plurality of stacked stampings.

[0108] Each segmented iron core 110 includes a connected stator yoke 112 and stator teeth 114, the stator teeth 114 are located between the axes of the stator yoke 112 and the stator iron core 100, and the stator yokes 112 of any two adjacent segmented iron cores 110 The stator slot 122 is surrounded by the stator teeth 114 .

[0109] The wall surface of the stator yoke 112 facing the axis of the stator core 100 is a split surface 124 ; along the circumferential direction of the stator core 100 , at least a part of the connection between the split surfaces 124 ...

Embodiment 3

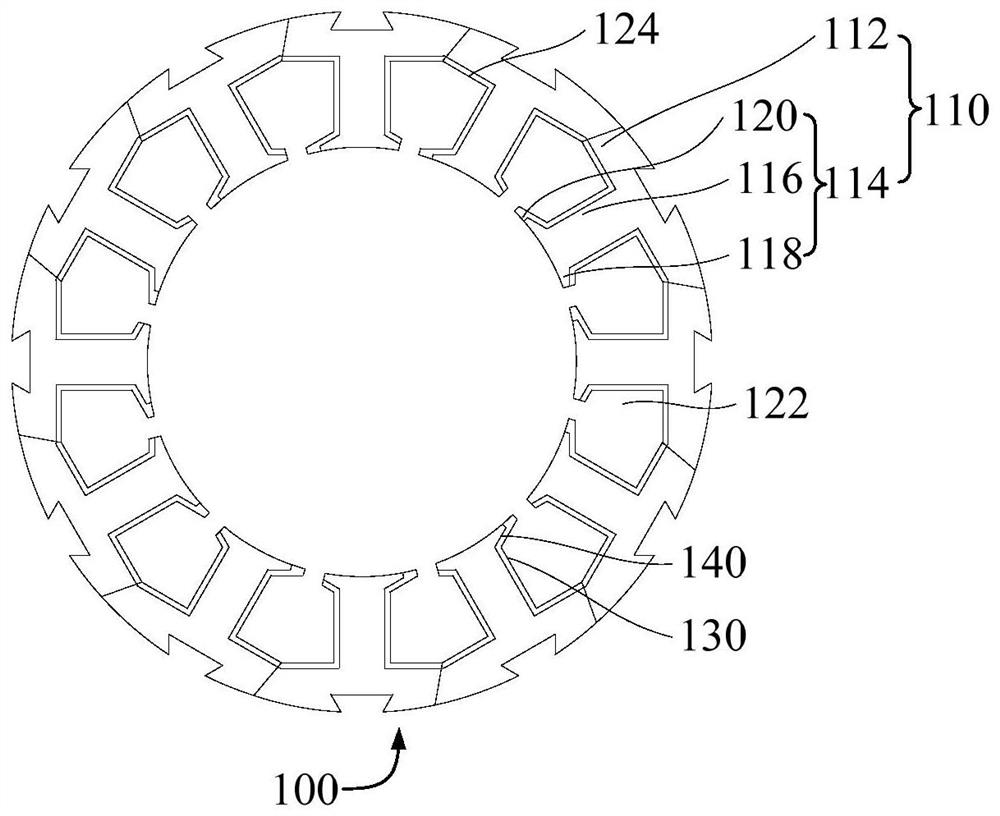

[0119] like Figure 1 to Figure 5 , Figure 8 , Figure 11 and Figure 12 As shown, on the basis of any of the above embodiments, Embodiment 3 provides a stator core 100, the stator core 100 includes a plurality of segmented iron cores 110, and the plurality of segmented iron cores 110 wind around the stator core 100 The axis lines are connected end to end in turn, and each segmented iron core 110 includes a plurality of stacked punching pieces.

[0120] Each segmented iron core 110 includes a connected stator yoke 112 and stator teeth 114, the stator teeth 114 are located between the axes of the stator yoke 112 and the stator iron core 100, and the stator yokes 112 of any two adjacent segmented iron cores 110 The stator slot 122 is surrounded by the stator teeth 114 .

[0121] The wall surface of the stator yoke 112 facing the axis of the stator core 100 is a split surface 124 ; along the circumferential direction of the stator core 100 , at least a part of the connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com