Auxiliary steel structure funnel segmented butt seam welding method

A butt welding and steel structure technology, applied in auxiliary welding equipment, auxiliary equipment, welding equipment, etc., can solve the problems of large size, large amount of misalignment, and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

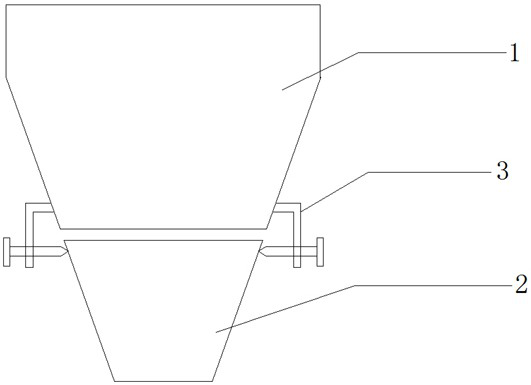

[0018] see figure 1 , figure 2 , a method for segmented butt seam welding of an auxiliary steel structure funnel, characterized in that it comprises the following steps:

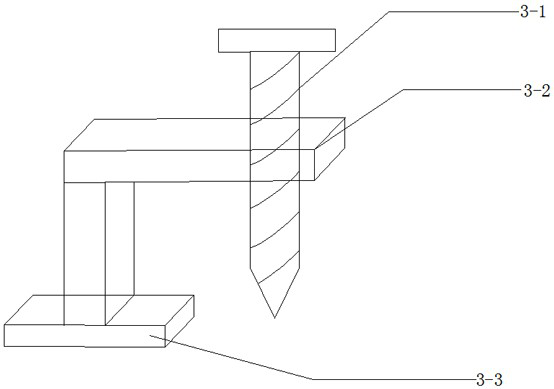

[0019] Step 1, processing and manufacturing the adjustable bolt device 3, the adjustable bolt device 3 includes a fixed plate 3-2 and an adjustable screw rod 3-1, and the fixed plate 3-2 has a screw hole matching the adjustable screw rod 3-1, which can be The adjusting screw 3-1 can rotate and move through the threaded hole;

[0020] Step 2, the adjustable bolt device 3 is evenly distributed on the upper part 1 of the steel structure funnel, the fixed plate 3-2 is fixed on the outer surface of the upper part 1 of the steel structure funnel nea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com