Automatic tracking system and method for gas shield welding of straight seam steel pipe pre-welding machine

An automatic tracking and pre-welding machine technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of poor anti-interference, achieve high anti-interference, perfect welding bead line, high reference value and promotion value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

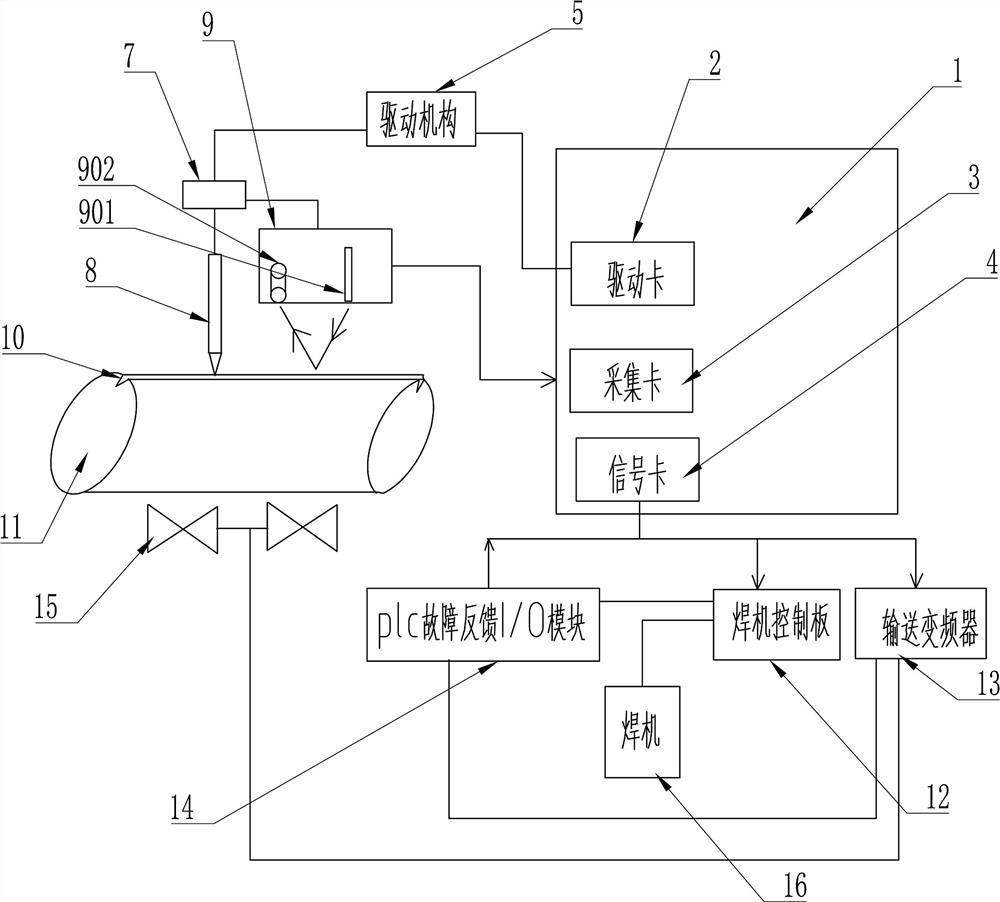

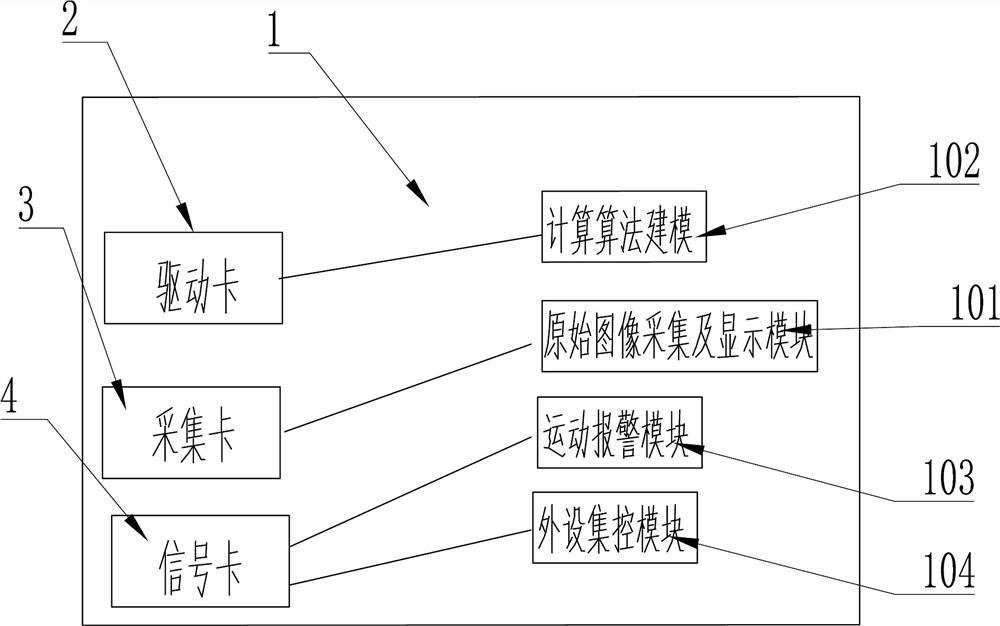

[0051] Such as Figure 1-2 Among them, a straight seam steel pipe pre-welding machine gas shielded welding automatic tracking system and method, including a drive system, the drive system includes a drive card 2 in a host 1, a drive mechanism 5, a welding torch bracket 7, a welding torch 8 and a visual sensor 9, the host The driving card 2 in 1 is connected to the driving mechanism 5 through the signal line, and the driving mechanism 5 is connected to the welding gun bracket 7, and the welding gun 8 and the visual sensor 9 are arranged on the welding gun bracket 7. With this structure, the system does not need an arc shield, and exhibits high anti-interference to arc spatter, which can successfully solve the problem of welding deviation caused by the poor anti-interference of imported tracking systems, and the tracking system has The linkage control function of equipment such as welding machines and conveyor drag chains has the advantage of one-button convenient operation.

...

Embodiment 2

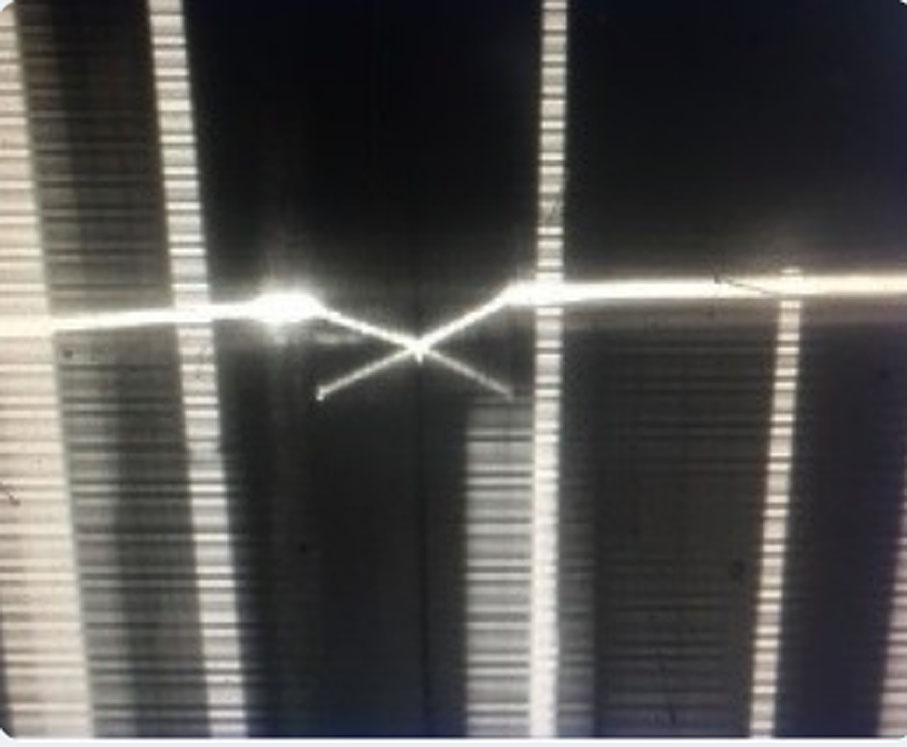

[0061] Further illustrate in conjunction with embodiment 1, as Figure 1-7 As shown, the method is: the laser stripe emitted by the laser emitter 901 of the visual sensor 9 hits the pre-welding groove 10, and the visual camera 902 transmits the image mixed with the arc light and the laser groove to the acquisition card 3; The image acquisition and display module 101 in the arc light is processed to obtain a clean groove image, and the calculation algorithm module 102 calculates the lowest point of the groove; the welding wire stretched out by the welding torch 8 is adjusted to the lowest point of the groove, remembering the groove center Position; the signal card 4 sends a driving signal to the welding machine control board 12 and the conveying frequency converter 13, the welding machine control board 12 controls the welding machine 6 to weld the tube blank 11, the conveying frequency converter 13 starts the conveying device 15 to rotate, and drives the tube blank 11 to move I...

Embodiment 3

[0063] Further illustrate in conjunction with embodiment 1, as Figure 3-4 As shown, the function of the neighborhood mean filter is to reduce image noise, realize image smoothing, and weaken and suppress most noise, such as noise caused by arc light and transmission channel. The basic idea is to perform template operation on the image matrix with the help of an average template, and replace the gray level of each pixel with the average value of several pixel gray levels. The mathematical expression is:

[0064]

[0065] In the above formula: f(x,y)-M×N pixel image; s-neighborhood set centered on (x,y), but including (x,y) points; F(x,y)- The image obtained after filtering; the total number of coordinate points in the M-set.

[0066] It can be seen from the above formula that the filtered image set is F(x, y), and the gray level of each pixel is determined by the average gray level of several pixels included in the predetermined neighborhood of f(x, y). of.

[0067] Her...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com