Flood control wall for water conservancy projects

A water conservancy project and wall technology, applied in water conservancy projects, sea area projects, embankments, etc., can solve the problems of poor flood control effect, difficult disassembly and assembly, etc., so as to achieve not easy bending and deformation, increased impact resistance, and good flood control effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

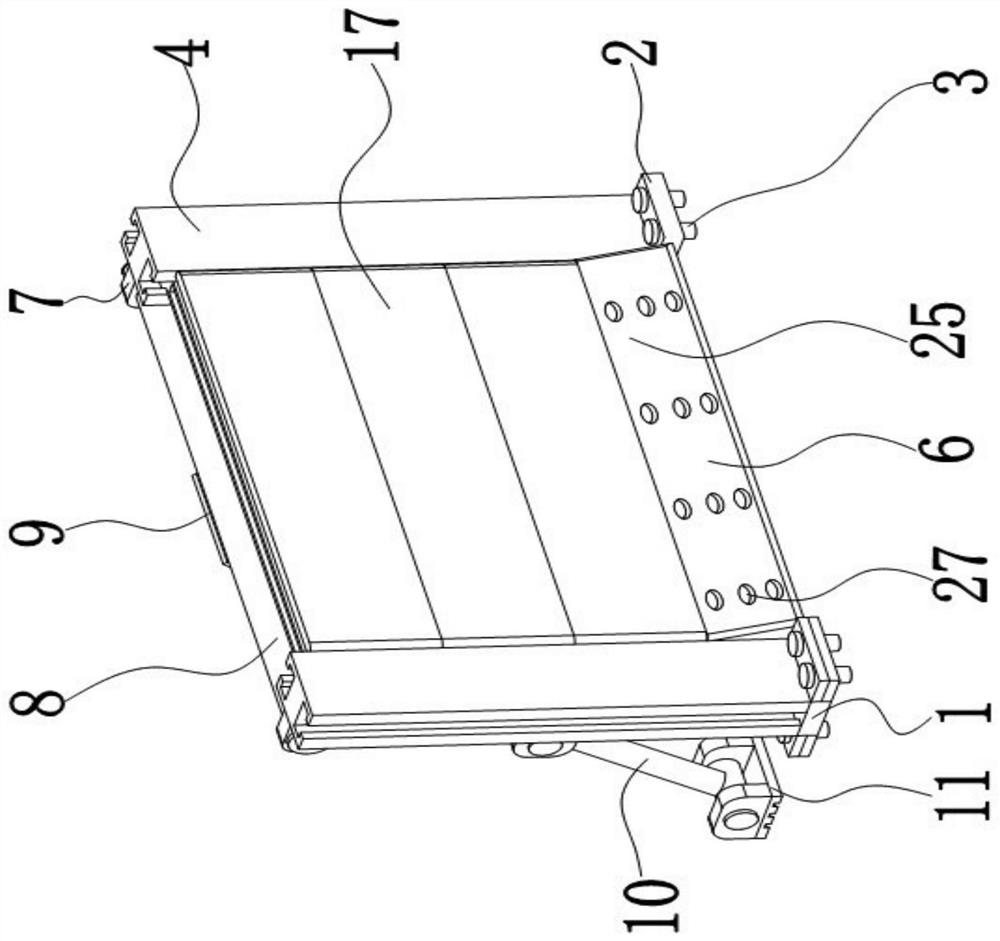

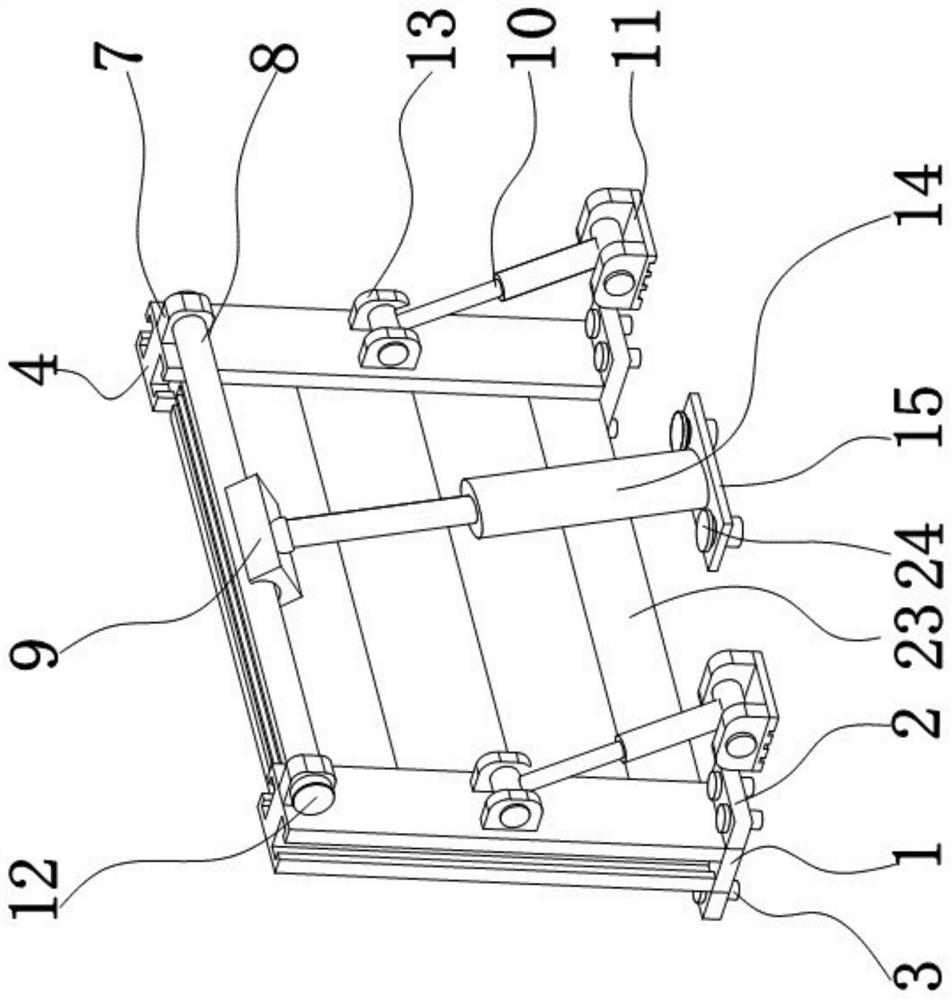

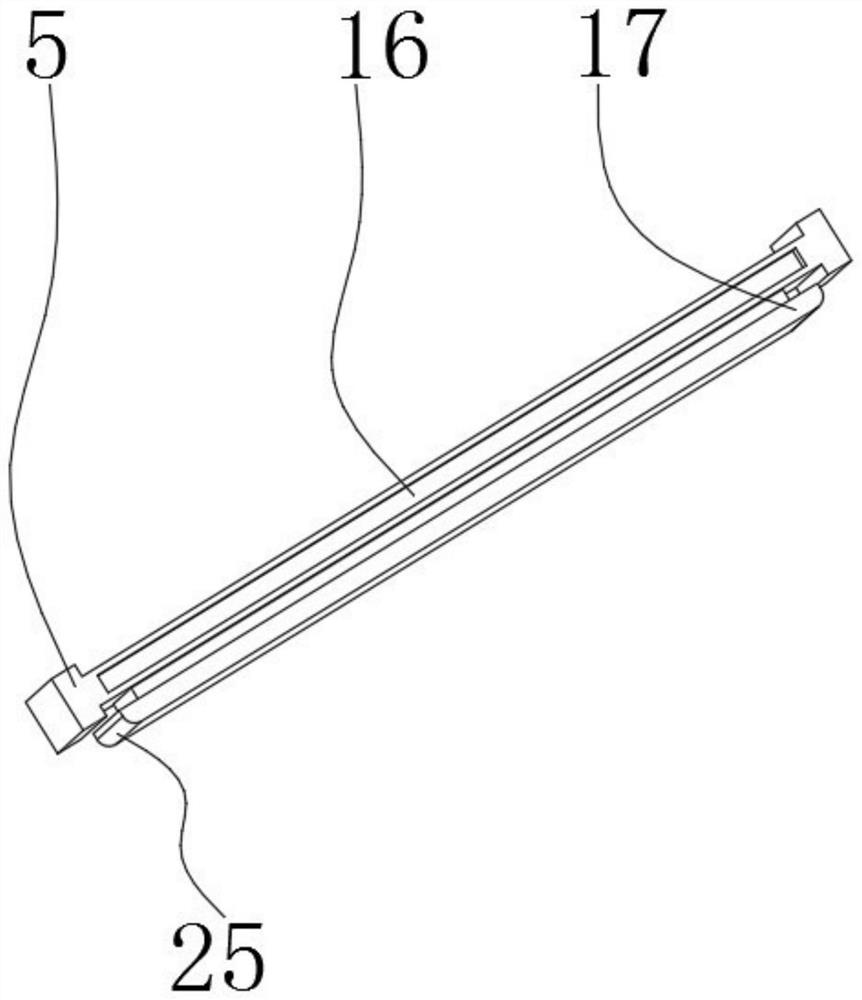

[0032] Such as Figure 1 to Figure 7 As shown, the present invention provides a flood control wall for water conservancy projects, including a base 1, a support frame 4 is sealed and rotated on the base 1, and a baffle 5 is movably connected to the inner side of the support frame 4, and the middle part of the top of the baffle 5 is opened. There is an inlay groove 16, a rectangular block 18 is fixedly installed in the middle of the right side of the baffle plate 5, a spring 19 is fixedly installed inside the rectangular block 18, a top plate 21 is fixedly connected to the right side of the spring 19, and a buffer is fixedly connected to the right side of the top plate 21 Plate 17, the left side of buffer plate 17 is provided with chute opening 20, and buffer plate 17 is sealed and slidably connected with rectangular block 18 through chute opening 20, and the bottom of baffle plate 5 is fixedly installed with mosaic block 22, and the bottom of mosaic block 22 is sealed It is mo...

Embodiment 2

[0041] Because floods are often accompanied by relatively large waves, if the waves of the flood directly impact the device repeatedly and repeatedly, it may cause the No. 1 fixing nail 3 and the No. 2 fixing nail 24 of the device to loosen or deform and damage other parts, resulting in This device loses the flood protection effect. Therefore, the device has been further improved.

[0042] Such as Figure 7-8 As shown, the support frame 4 is sealed and rotated on the base 1, the sealing part 6 is provided with a second pipeline 27, the buffer plate 17, the rectangular block 18 and the baffle plate 5 form a second cavity 602, and the second pipeline 27 makes the first The second cavity 602 communicates with the outside of the device to guide a part of the flood into the second cavity 602 through the second pipeline 27; The outlet is connected with the second pipeline 27, and the outlet is provided with a filter screen, which can filter debris in the flood to prevent the secon...

Embodiment 3

[0046] After the flood recedes, when the device is recycled, because the flood contains a lot of silt and fine debris after being filtered by the filter screen on the outlet, the silt and fine debris etc. gather in the second cavity 602, if not Cleaning up in time will cause the spring 19 to be rusted and damaged; excessively small foreign matter blocked in the second cavity 602 will cause the spring 19 to be unable to be compressed, so before recycling the device, it is necessary to clean the mud in the second cavity 602. Clean up sand, debris, etc.

[0047] Such as Figure 7-8 As shown, a first cavity 601 is provided in the sealing portion 6, and the first cavity 601 communicates with the second cavity 602 formed by the buffer plate 17, the rectangular block 18 and the baffle plate 5 through the first pipeline 26; the first pipeline 26 is provided with a one-way valve 28; the outer end of the second pipeline 27 is provided with a sealing plug.

[0048]A first cavity 601 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com