A Binary Adjustable Nozzle with Spherical Seal

A spherical sealing and nozzle technology, used in jet propulsion devices, machines/engines, etc., can solve problems such as poor sealing, prevent high-temperature gas leakage, improve sealing effect, and facilitate installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

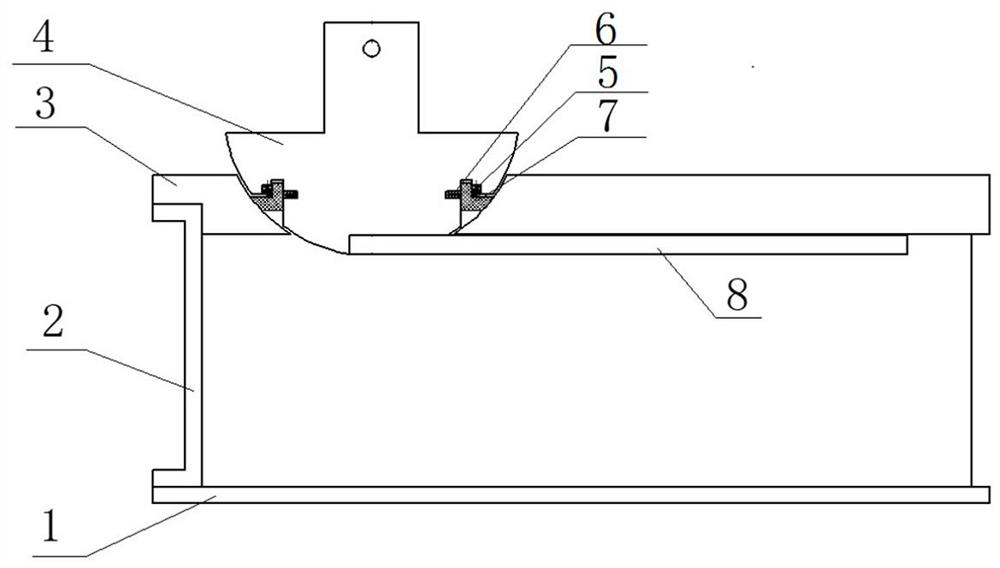

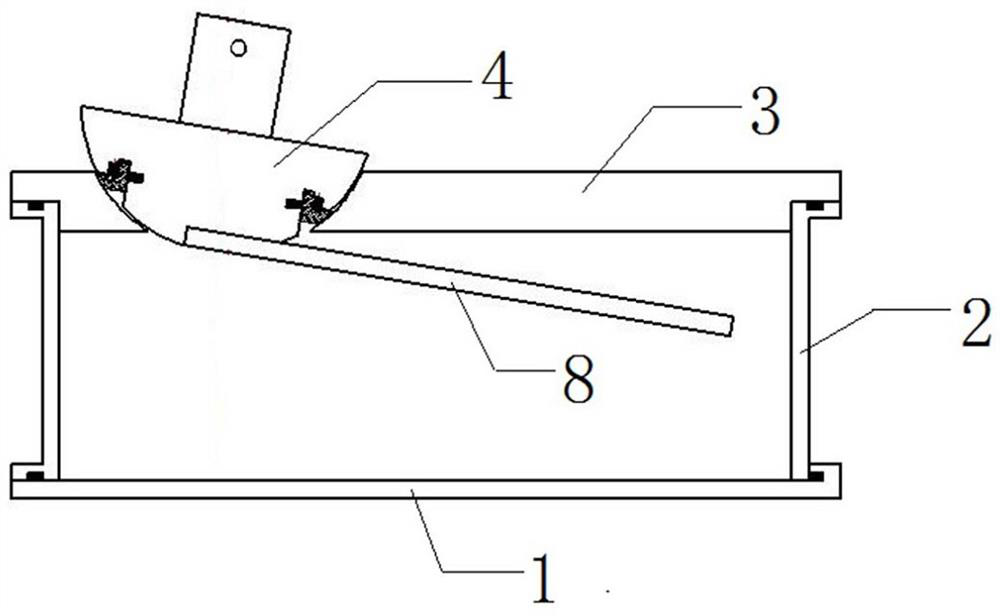

[0046] Such as Figure 1-8 A binary adjustable nozzle adopting a spherical seal is shown, including a nozzle body, a sealing ball seat 4 , a sealing structure and an adjusting plate 8 .

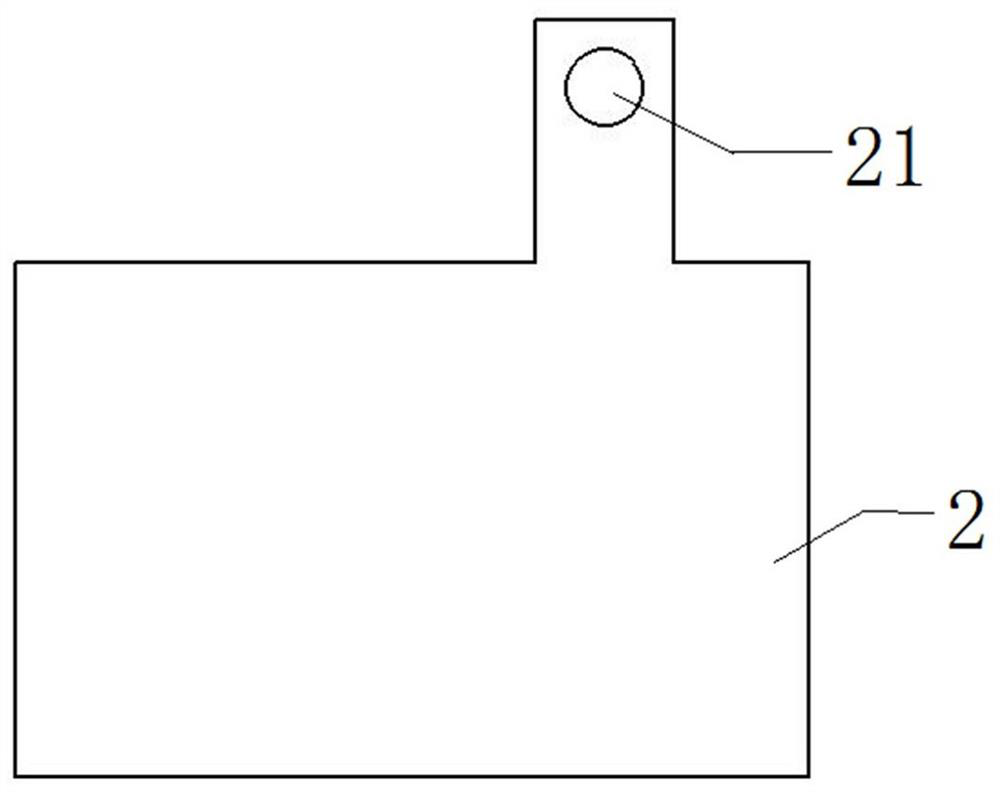

[0047] In this embodiment, the nozzle body includes a bottom plate 1 , a side plate 2 connected to the bottom plate 1 , and a top plate 3 connected to the side plate 2 and opposite to the bottom plate 1 . The bottom plate 1 is rectangular and is the bottom surface of the nozzle body. There are three side plates 2, which are fixed to the bottom plate 1 by screws, and sealing strips are installed in the groove positions. The bottom plate 1, the side plate 2 and the top plate 3 enclose to form a nozzle cavity with an air outlet on one side. The top plate 3 is rectangular, and the top plate 3 is provided with spherical holes 31 with openings at both ends. The sealing ball seat 4 is installed on the spherical hole 31 of the top plate 3 in a rotatable manner around an axis, and the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com