Self-locking retaining device and retaining method for pipe jacking construction

A backstop device, self-locking technology, applied in mining equipment, shaft equipment, earthwork drilling and mining, etc., can solve problems such as limited effect, no backstop device with adjustable backstop force, unstable soil surface pressure, etc. Achieve the effects of improving the effect, good structural stability, improving construction quality and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

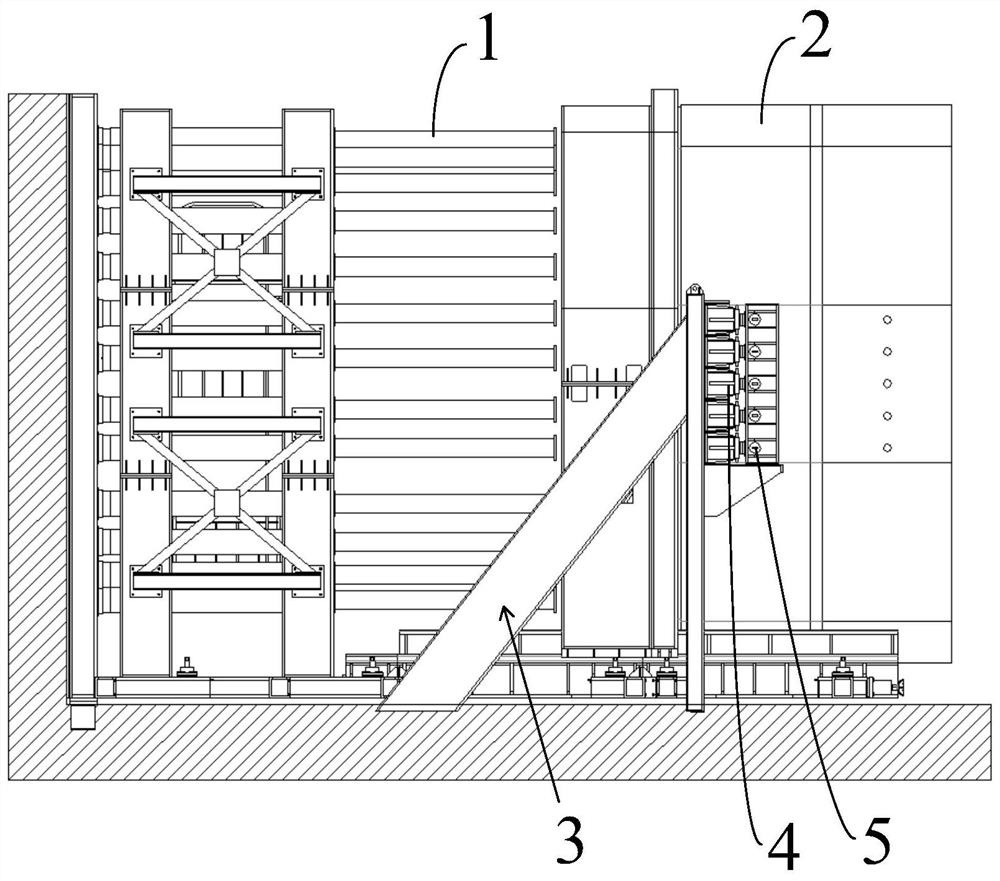

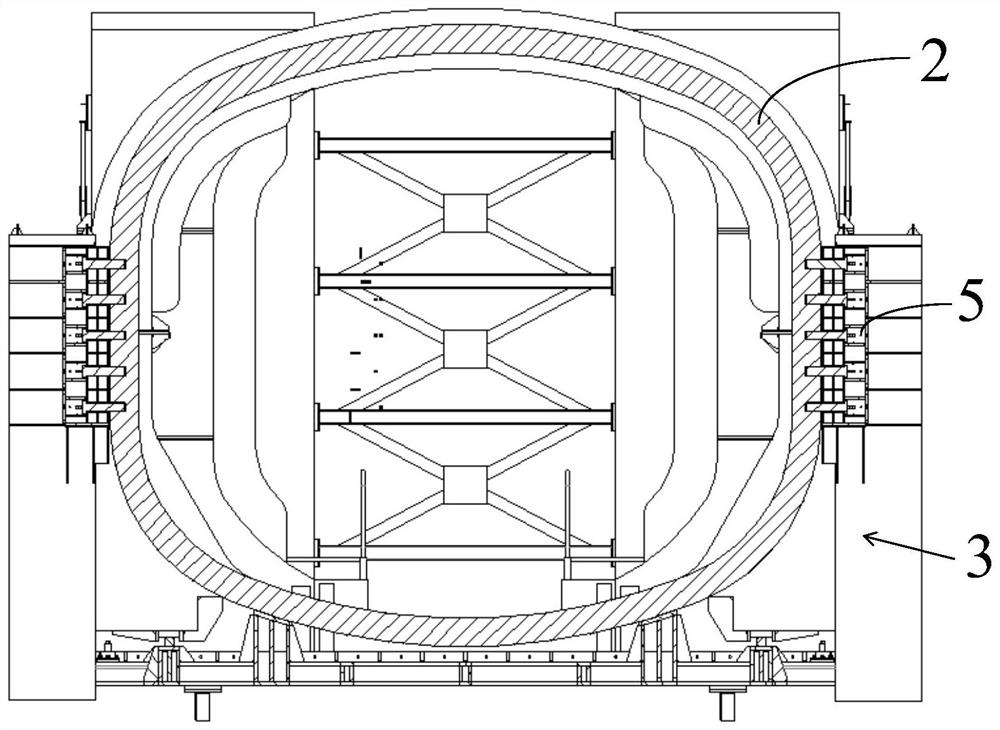

[0037] Such as Figure 1-3 As shown, the self-locking anti-retraction device for pipe jacking construction according to the embodiment of the present invention includes: two sets of anti-retreat brackets 3 installed in the originating shaft, and the two sets of anti-retreat supports 3 are respectively arranged on opposite sides of the segment ring It is arranged along the axial direction of the segment ring; multiple sets of connectors 5 are detachably connected to the segment ring 2; a plurality of mechanical self-locking jacks 4 for pushing the segment ring 2 along the pipe jacking direction are respectively installed on The two sets of backstop brackets 3 are fixedly connected with the connectors one by one; they are used to control the hydraulic control system of the mechanical self-locking jack 4 .

[0038] The two sets of anti-retraction devices are respectively connected to the opposite side walls of the segment ring 2, so that the opposite side walls of the segment rin...

Embodiment 2

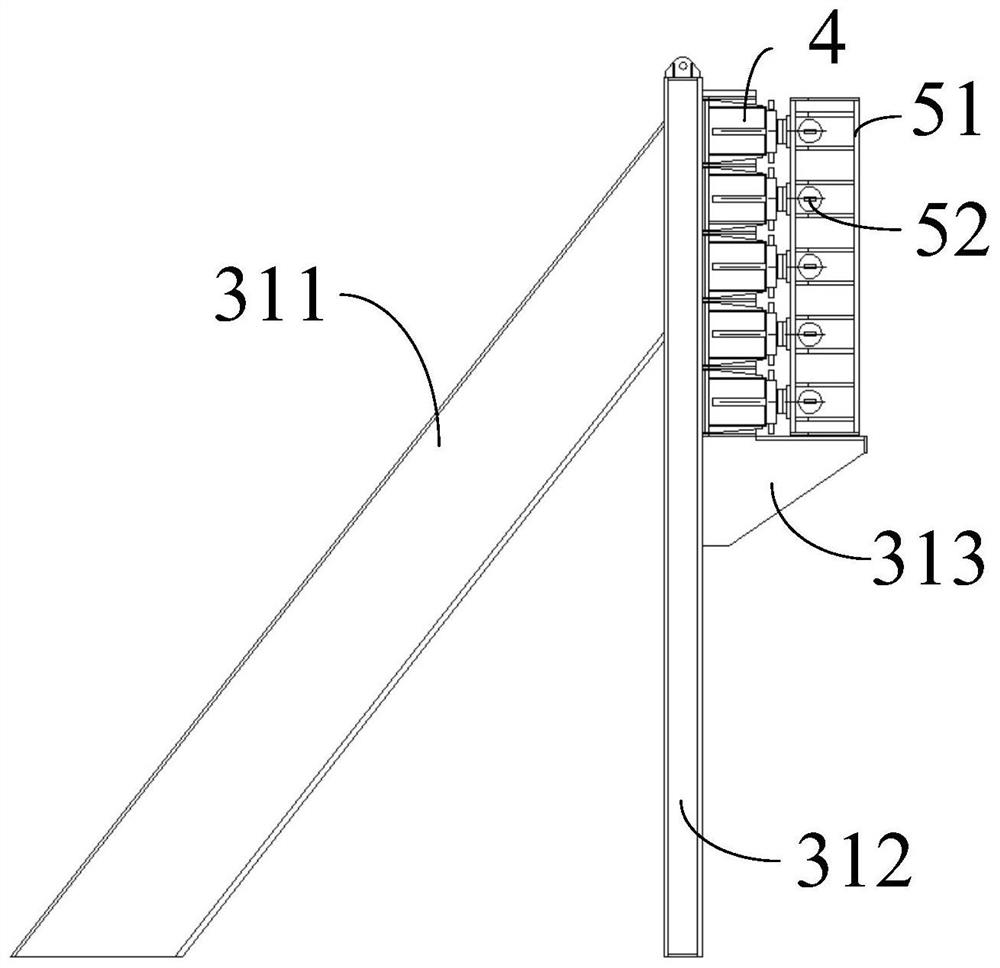

[0048] The difference from the first embodiment lies in the structure of the backstop bracket 3 .

[0049] Such as Figure 4-5 As shown, the self-locking anti-retraction device for pipe jacking construction according to the embodiment of the present invention includes:

[0050] Two sets of anti-retraction brackets 3 installed in the originating shaft, the two sets of anti-retraction brackets 3 are respectively arranged on opposite sides of the segment ring and arranged along the axial direction of the segment ring; Connecting piece 5; a plurality of mechanical self-locking jacks 4 used to push the segment ring 2 along the pipe jacking direction, respectively installed on two sets of anti-retraction brackets 3 and fixedly connected with the connecting piece one by one; used to control Hydraulic control system of mechanical self-locking jack 4.

[0051] The two sets of anti-retraction devices are respectively connected to the opposite side walls of the segment ring 2, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com