A tower crane type concrete conveying device

A conveying device and concrete technology, which is applied in the direction of transportation, packaging, cranes, etc., can solve the problems of installation and disassembly being restricted by the installation location, concrete construction cannot be carried out, and the distribution range of the distribution machine is small, so as to improve uniformity and convenience. The effect of height increase, service life and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

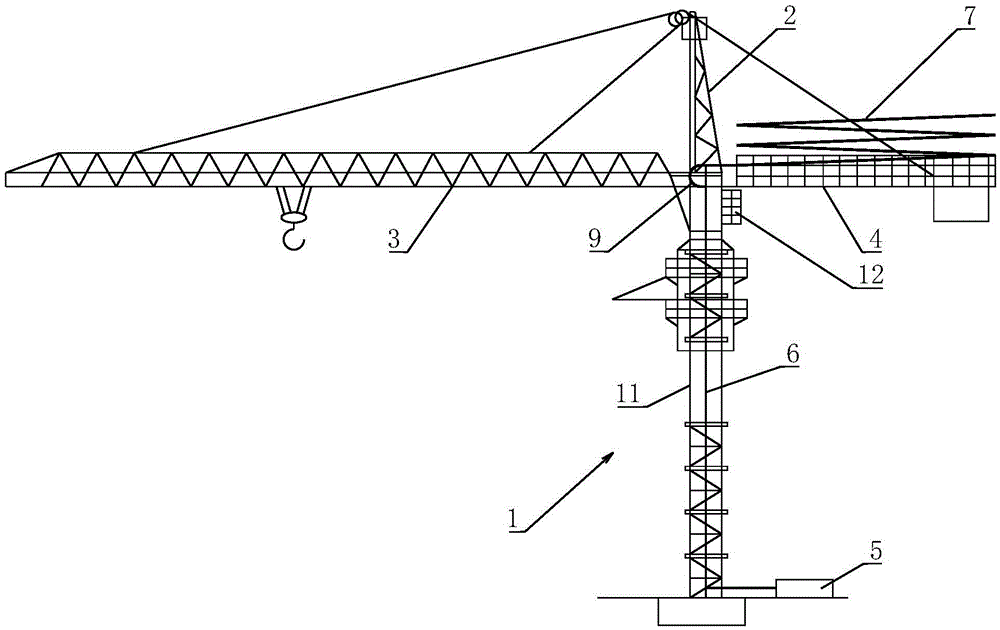

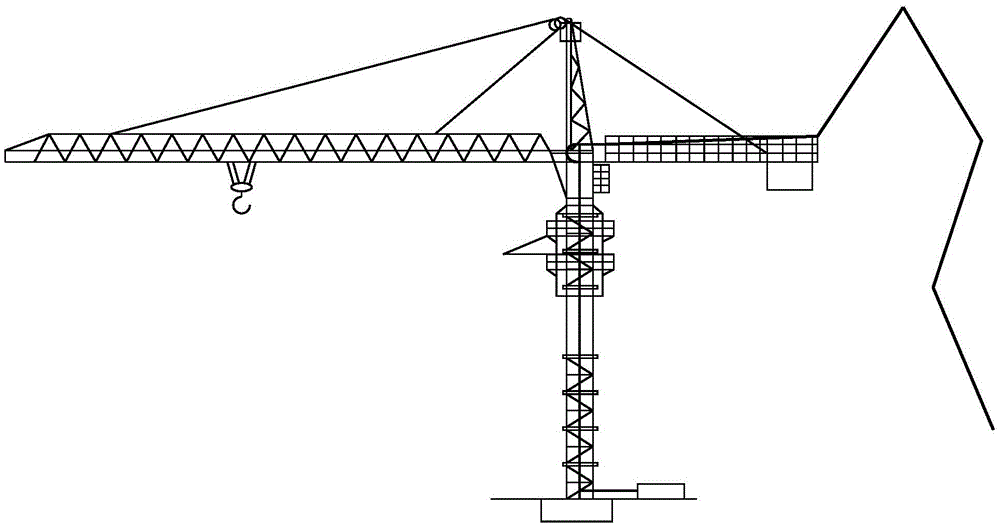

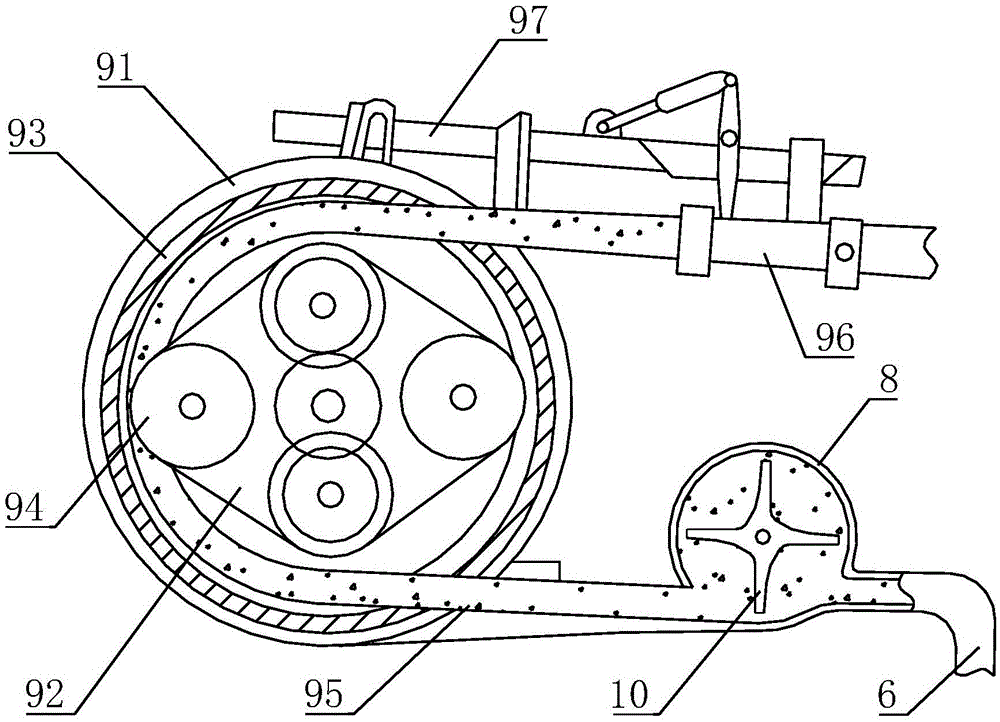

[0025] A kind of tower crane type concrete conveying device of the present invention, as figure 1 As shown, it includes a tower 1, a tower cap 2 arranged on the upper end of the tower 1, a lifting arm 3 and a balance arm 4 horizontally connected to the upper end of the tower 1 through a turntable, and a feeding pump 5, a feeding pipe 6 and an arm Frame 7; the boom 7 is folded and arranged on the balance arm 4, the input end of the boom 7 is connected to the output end of the feeding pump 5 through the feeding pipe 6 fixed on the tower 1, and the feeding pump 5 is arranged on the tower 1 outside of the base; as image 3 As shown, the delivery pipe 6 is provided with an acceleration pump 8 for accelerating the flow of concrete material, and a supercharging device 9 is arranged downstream ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com