Rotary knob rotation detection method and rotary knob assembly

A technology of rotation detection and knob, applied in measuring devices, control components, instruments, etc., can solve the problems of low reliability, susceptibility to electromagnetic interference, and high cost of magnetic angle sensors, and achieve the effect of preventing electromagnetic interference and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

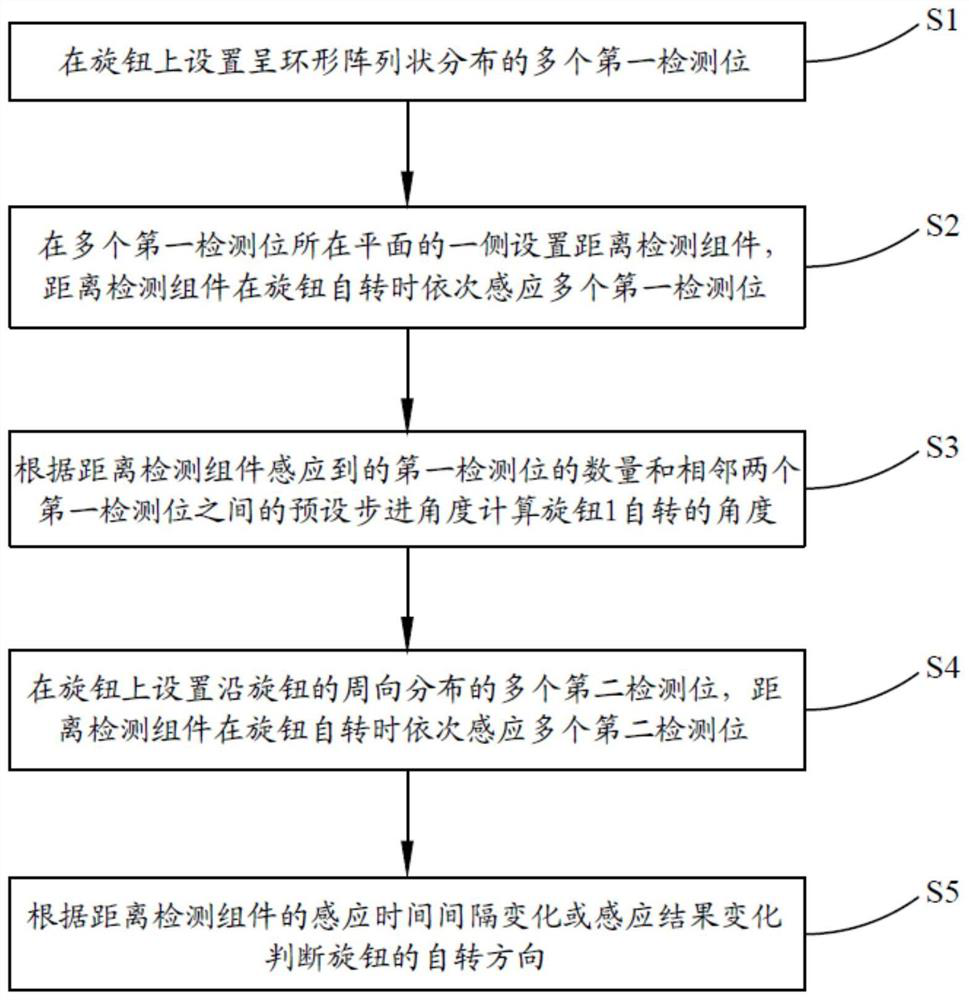

[0056] Such as figure 1 As shown, the rotation detection method of the knob provided in this embodiment includes:

[0057] Step S1: setting a plurality of first detection bits 10 distributed in a circular array on the knob 1;

[0058] Step S2: Install a distance detection component 2 on one side of the plane where the multiple first detection positions 10 are located, and the distance detection component 2 senses the multiple first detection positions 10 sequentially when the knob 1 rotates;

[0059] Step S3: Calculate the rotation angle of the knob 1 according to the number of the first detection positions 10 sensed by the distance detection component 2 and the preset step angle between two adjacent first detection positions 10 .

[0060] Wherein, since the plurality of first detection positions 10 are distributed in a circular array, the included angle between two adjacent first detection positions 10 in each group is equal, and the included angle is a preset step angle. W...

Embodiment 2

[0095] Such as Figure 7 As shown, the knob assembly provided in this embodiment includes a knob 1 and a distance detection assembly 2 . The knob 1 is provided with a plurality of first detection bits 10 distributed in a circular array. The distance detection component 2 is arranged at intervals on one side of the plane where the plurality of first detection positions 10 are located, and is used to sequentially sense the plurality of first detection positions 10 during the rotation of the knob 1 to calculate the angle after the rotation of the knob 1 .

[0096] After the knob 1 in the knob assembly rotates, the distance detection assembly 2 can sense a plurality of first detection positions 10 in sequence. Since a plurality of first detection positions 10 are distributed in a circular array, the angles between two adjacent first detection positions 10 in each group are equal, and the angle is a preset known value. The detected number of digit 10, combined with the above incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com