Frameless magnetic bearing stator and coil winding tool and winding method thereof

A bearing stator, skeletonless technology, applied in coil manufacturing, magnetic bearings, bearings, etc., can solve the problem of high manufacturing cost, and achieve the effect of improving winding efficiency, reducing production cost and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

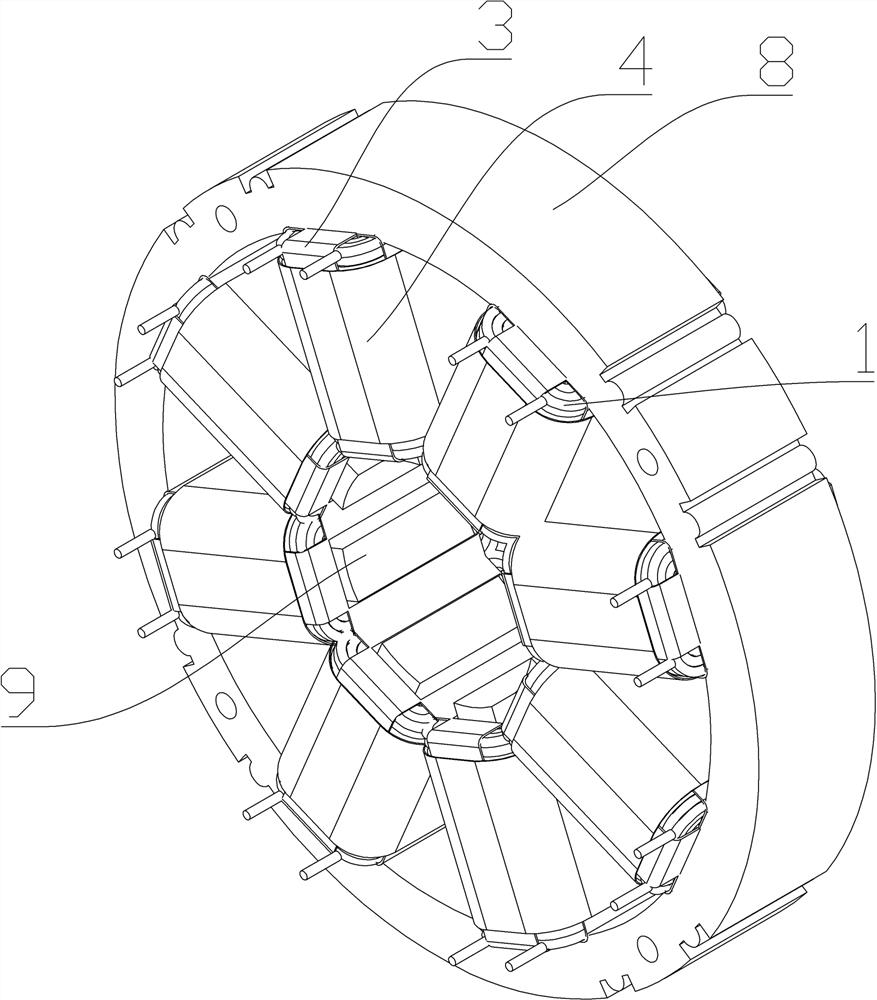

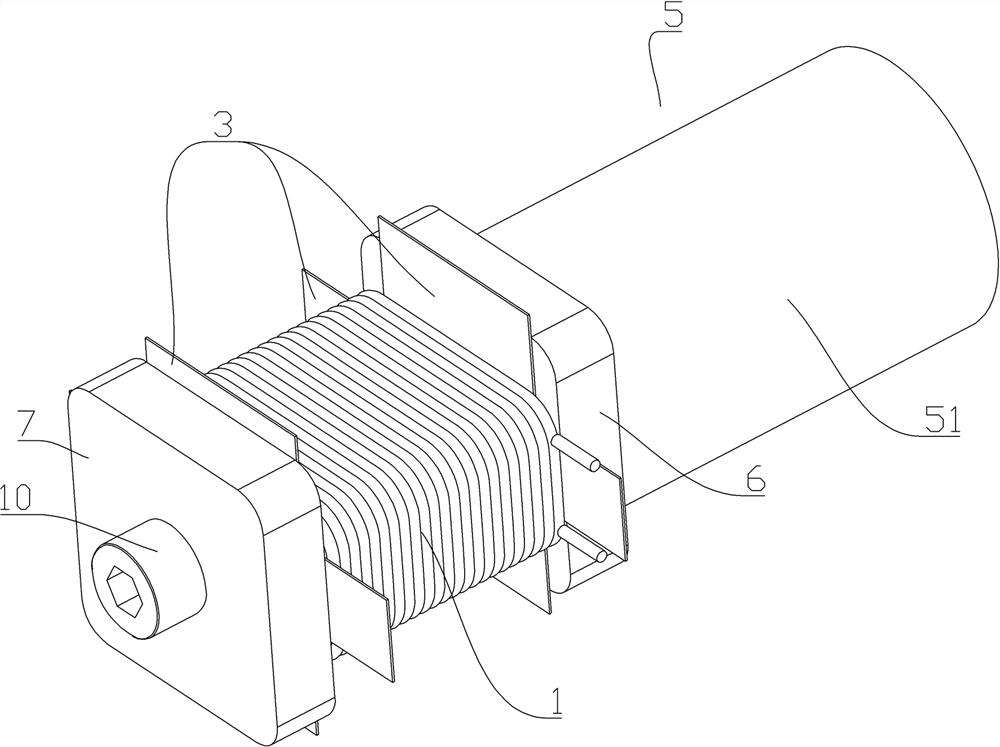

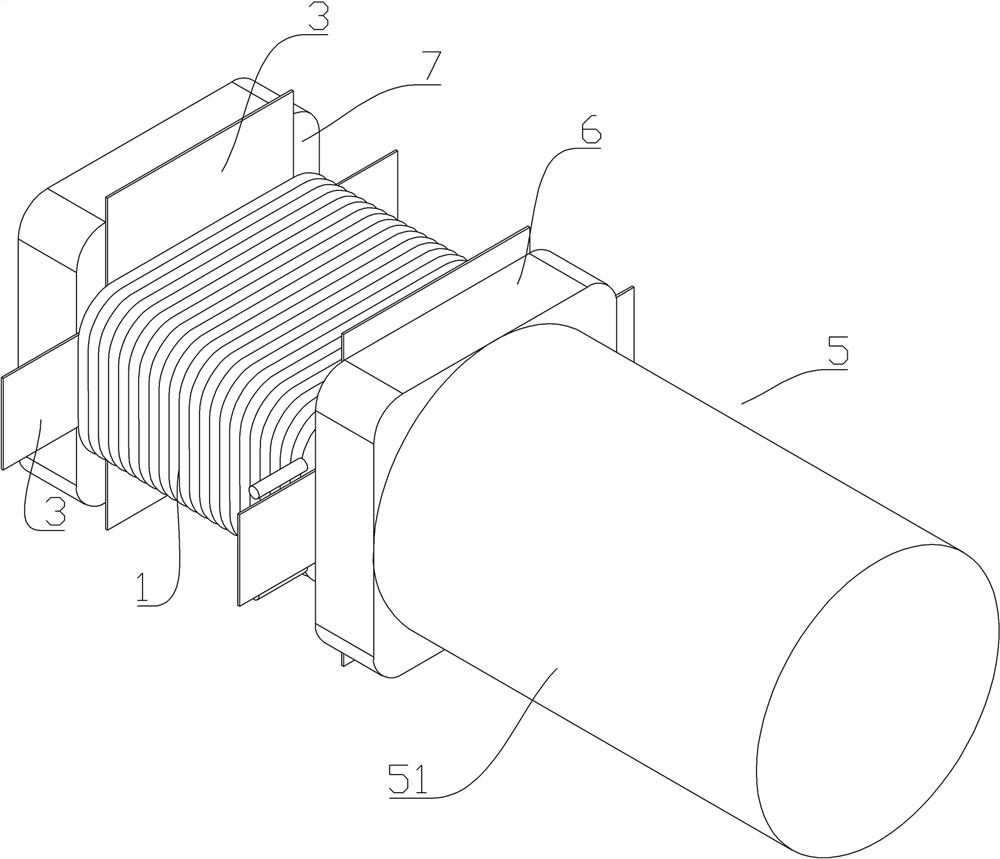

[0043] Such as Figure 1 to Figure 6 As shown, the frameless magnetic bearing stator includes a stator ring 8, an iron core 9, and a coil 1. The iron core 9 is arranged on the stator ring 8, and the coil 1 is located on the periphery of the iron core 9; there is a paper tube 2 between the coil 1 and the iron core 9. , the coil 1 is wound on the paper tube 2, and the paper tube can maintain the shape of the coil and is not easy to disperse. In order to facilitate the installation of the coil 1, reduce the deformation of the coil 1, and reduce the scratching of the coil 1 during installation, both ends of the paper tube 2 have protective strips 3 that extend out of the coil 1 and are folded outward to meet the end surface of the coil 1. The protective strip 3 is folded from the end surface of the coil 1 to the outer peripheral surface of the coil 1 and pasted on the outer peripheral surface of the coil 1 . The protective strip 3 is L-shaped, one of the two folded edges is attac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap