A kind of LED epitaxial structure, LED chip and LED epitaxial structure preparation method

An epitaxial structure and scope technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of poor ohmic contact in the production of electrodes, laser peeling damage, etc., and achieve the effect of enhancing success rate and yield, and improving leakage rate increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] For the convenience of description, this paper uses terms representing relative positions in space to describe, such as "upper", "lower",

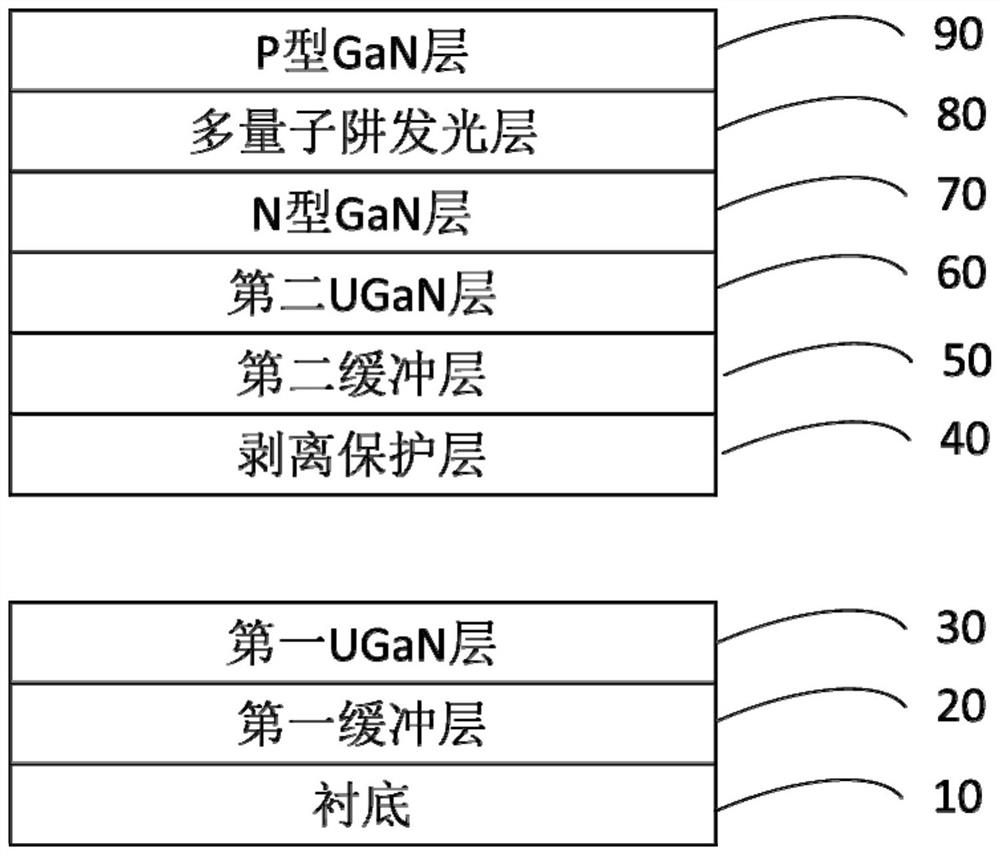

[0040] The LED epitaxial structure sequentially includes a substrate 10, a first buffer layer 20, a first UGaN layer 30, and a lift-off protection from bottom to top

[0041] As shown in FIG. 2, the first UGaN layer 30 is peeled off using an existing lift-off technology (eg, laser lift-off technology), and the

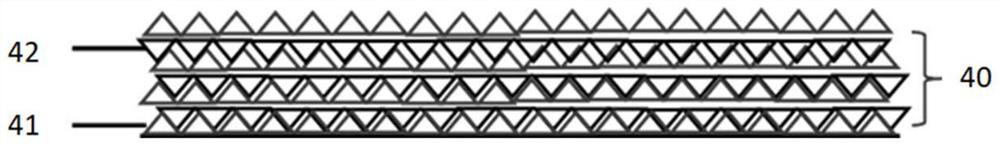

[0044] Here, the exfoliation protective layer 40 is an example of a composite structure of Al / AlGaN for illustration, of course, in other implementations

[0047] FIG. 4 is a schematic diagram of an LED chip in the present invention, please refer to FIG. 4 .

[0048] The LED chip includes the above-mentioned LED epitaxial structure (stripping the protective layer 40, the second buffer layer 50, the second UGaN layer 60, the N

[0051] Step S1: growing the first buffer layer 20 and the first UGaN layer 30 on the substrate 10;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com