Multi-blade rotary feeding pipe cutting cutterhead and pipe cutter

A technology of pipe cutter and cutter head, which is applied in the direction of pipe shearing device, shearing device, shearing machine equipment, etc., can solve the problems of low operation efficiency, difficulty in multiple blades, wrist damage, etc., and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

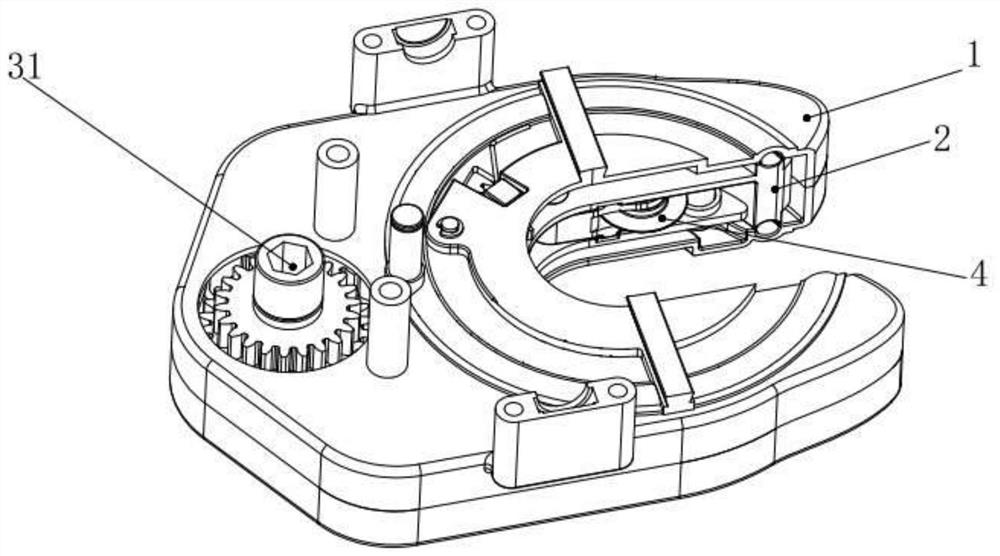

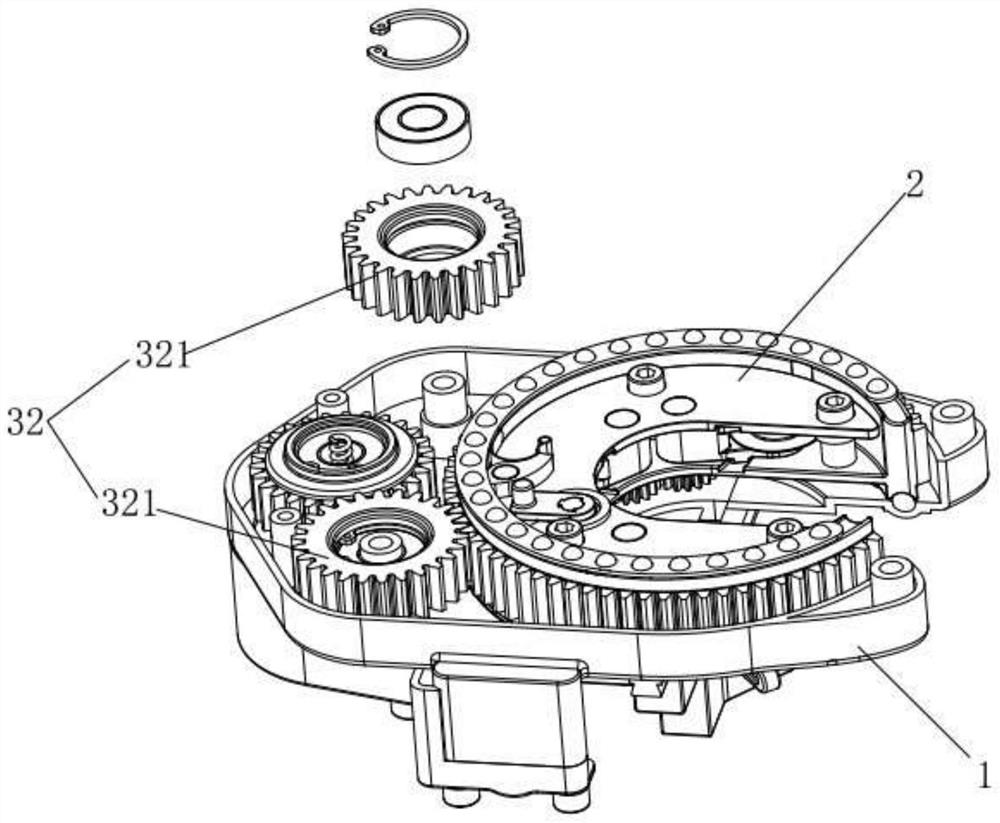

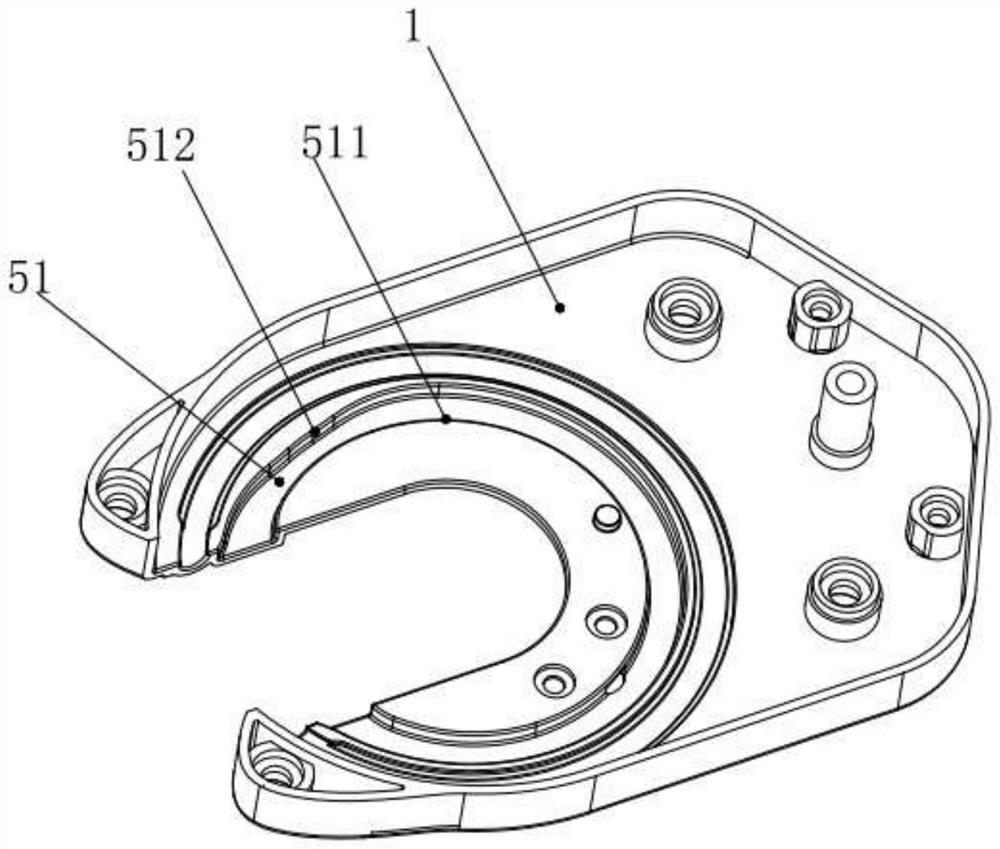

[0059] Such as Figure 1-10 As shown, the multi-blade rotary feed pipe cutting cutterhead 10 includes a housing 1 and also includes:

[0060]The cutter head 2 is installed in the casing 1 through the ball bearing positioning structure 21 arranged on both ends of the cutter head 2 and can rotate around its axis. Both the casing 1 and the cutter head 2 are provided with The through hole in the center forms a cutting space for placing the cutting object (pipe) in the through hole; the cutter head 2 is a ring-shaped structure (ie a C-like structure) with an opening, and the housing 1 is also provided with a corresponding The opening, the opening of the cutter head 2 and the opening of the casing 1 communicate with the cutting space. The effect of setting the opening on the cutter head 2 and the housing 1 is to facilitate the pipe cutting cutter head 2 to be directly placed on the pipe at any position of the pipe to be cut for cutting, which is convenient for use.

[0061] The cu...

Embodiment 2

[0072] On the basis of embodiment 1 technical scheme, make following improvement:

[0073] Such as Figure 11-15As shown, the cutter head 2 is installed in the casing 1 through a ball positioning structure arranged on the outer ring of the cutter head 2 . The quantity of described knife rest is three, is respectively knife rest a41, knife rest b42 and knife rest c43, is arc-shaped structure and the outer side is provided with rack, the side of each knife rest and described cutter head 2 respectively Matching arc-shaped guide protrusions and arc-shaped guide grooves are provided, and the tool post linkage 53 also includes a reverse linkage rack 532, and the feed gear 522 is connected to the reverse direction through a driven feed gear 5221. Linkage rack 532, thereby make reverse linkage rack 532 and described forward linkage rack 531 movement directions opposite, one end of knife rest is equipped with described blade 4, wherein the rack of knife rest a41 and knife rest b42 are...

Embodiment 3

[0076] On the basis of embodiment 1 technical scheme, make following improvement:

[0077] Such as Figure 16 As shown, the number of the tool holders is three, which are respectively the tool holder a41, the tool holder b42 and the tool holder c43. One end of the tool holder a41 is hinged on the cutter head 2 and is provided with the cutter bar gear a4111, and the other end The blade 4 is installed, one end of the knife rest b42 is hinged on the cutter head 2 and is provided with the cutter bar gear b4211, the other end is equipped with the blade 4, and one end of the knife rest c43 is hinged on the cutter head 2 There is also a cutter bar gear c4311, and the blade 4 is installed at the other end, wherein the cutter bar gear a4111 and the cutter bar gear b4211 are both meshed with the forward linkage rack 531, and the cutter bar gear c4311 is meshed with the cutter bar gear a4111. This design makes when the knife rest linkage 53 rotates in the forward direction, it will driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com