Composite pile for ground foundation engineering

A technology for foundation engineering and combined piles, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as difficulty in pulling out foundation piles, hidden dangers of building safety, etc., and achieve material saving, foundation pile stability, and good use effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

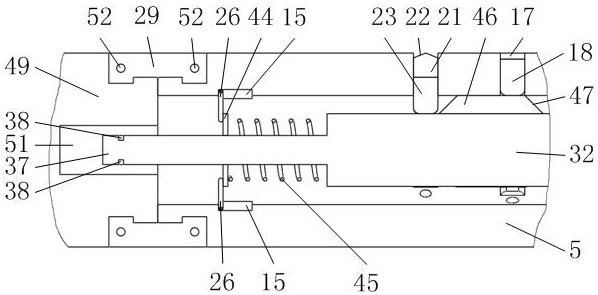

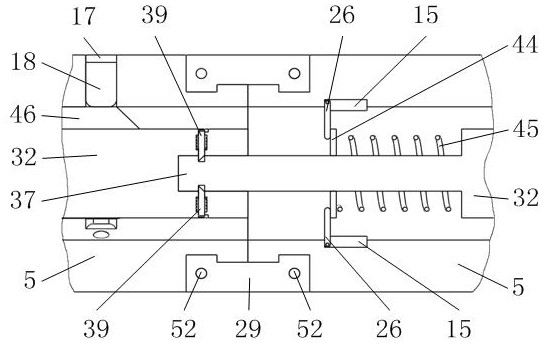

[0037]The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

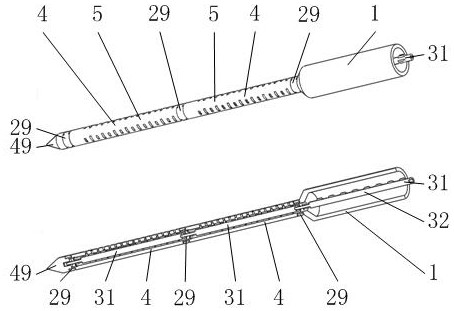

[0038] Such as figure 1 Shown, it comprises top pile tube 1, bottom pile mechanism 4, taper head 49, solid pile mechanism 31, wherein as figure 2 , 3 , 4, one end of several lower pile mechanisms 4 that are connected successively is equipped with a conical head 49 that facilitates its insertion into the foundation, and the other end is equipped with an upper pile pipe 1 that is larger in diameter and communicates with it; figure 1 , 2 , 3, each lower pile mechanism 4 is equipped with a pile fixing mechanism 31 that is fixed in the foundation, and two adjacent pile fixing mechanisms 31 are detachably connected.

[0039] Such as Figure 12 Shown, above-mentioned bottom pile mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com