Aluminum alloy special-shaped door and window

An aluminum alloy and special-shaped technology, applied in the field of aluminum alloy doors and windows, can solve the problems of inconvenient rainwater cleaning, easy accumulation of rainwater, easy accumulation of dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

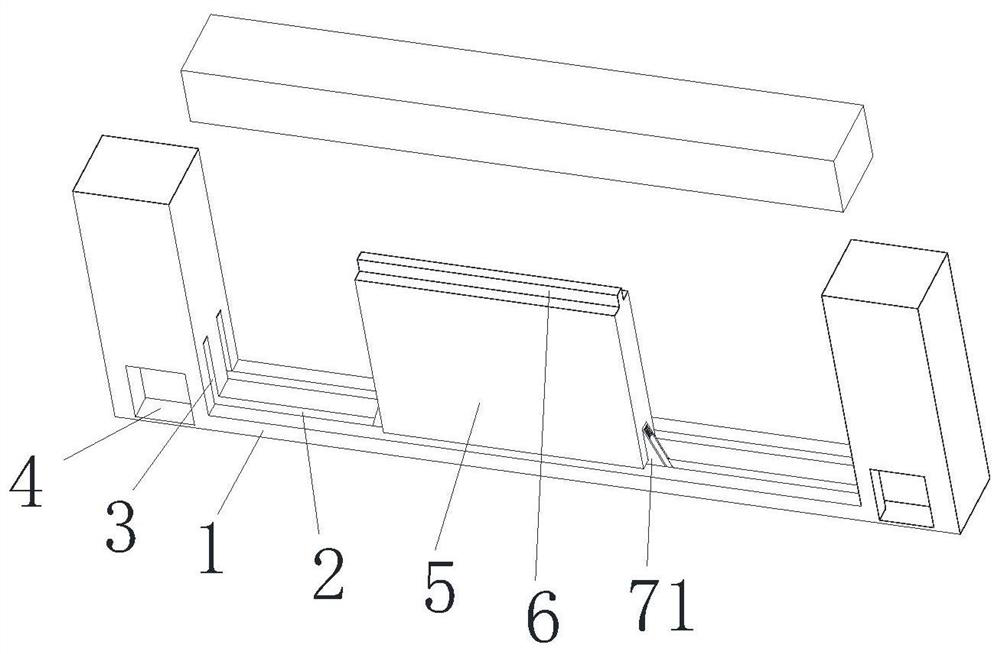

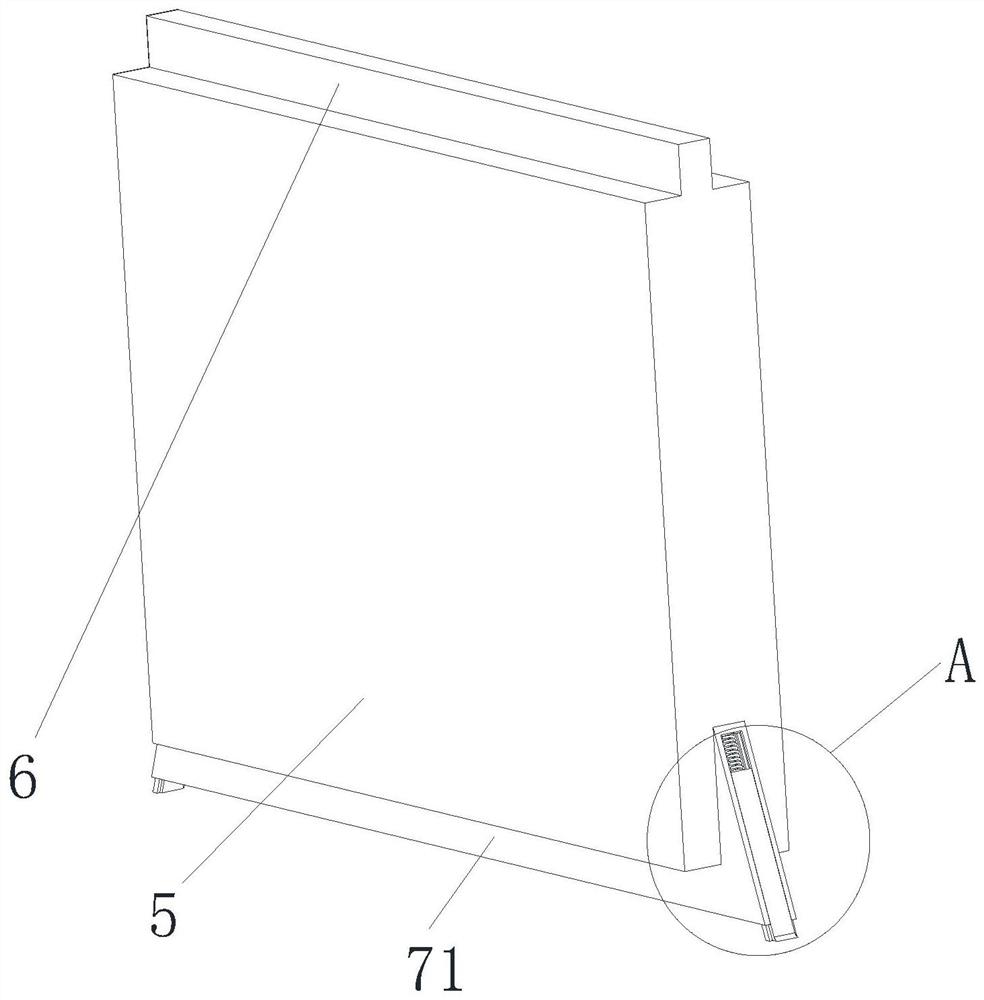

[0032] like Figure 1 - Figure 3 As shown, an aluminum alloy shaped doors and windows, including door frame 1, two sets of sliding grooves 2 in the bottom of the door frame 1, and two sets of grooves 3 are opened on both sides of the door frame 1, and the door frame 1 Two sets of cleaning grooves 4 are opened on both sides of the front and rear, and the cleaning groove 4 is connected to the groove 3, the door frame 1 is attached to the window 5, and the window 5 is fixedly mounted with a sliding block 6, the window 5 The cleaning device is provided below, and the wall surface of the internal corresponding door frame 1 of the cleaning groove 4 has a mounting groove 11, the mounting groove 11 is a circular groove, and the internal activity of the mounting groove 11 is mounted with a rotating shaft 12, a rotating shaft 12. For a circular column, the bottom end of the rotating shaft 12 is fixedly mounted having a baffle 13, a triangular block, and a side surface of the baffle 13 mounts...

Embodiment 2

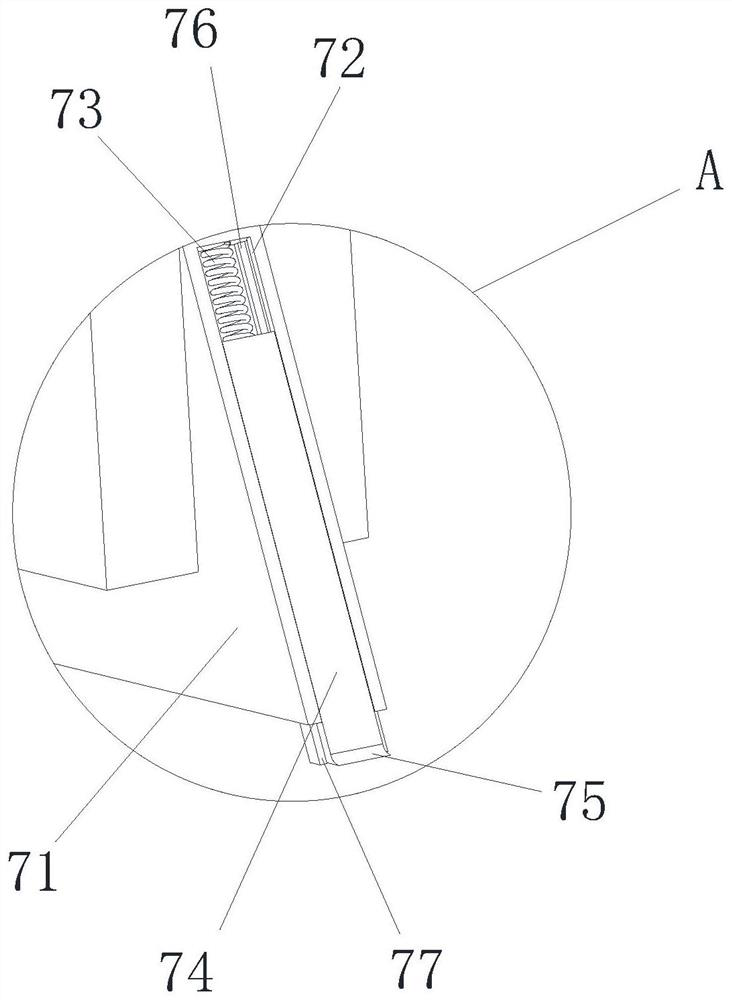

[0034] On the basis of the example, such as Figure 1 - Figure 3 with Figure 8 As shown, the sweep means includes a first cleaning block 71, and the first cleaning block 71 is fixedly mounted below the window 5, and the first cleaning block 71 is a trapezoidal block shape, and the first cleaning block 71 has a left and right sides of the left and right sides. The active tank 72 is opened, the movable groove 72 is a rectangular groove, and the moving spring 73 is fixed to the wall surface of the first cleaning block 71, and the moving spring 73-bit has a technique not described herein. The lower end of the extrusion block 74 is fixedly mounted with an arcuate block 75, and the window 5 is a curved block;

[0035] The card slots 76 are opened on both sides of the first cleaning block 71 in the left and right sides of the movable groove 72, and the card slot 76 is a rectangular groove, and the left and right sides of the extrusion block 74 are fixedly mounted. 77 The block 77 is a rec...

Embodiment 3

[0038] On the basis of the example, such as Figure 4 - Figure 6As shown, the sweeping device includes a second cleaning block 81, and the second cleaning block 81 is a ladder block shape, and the left and right sides of the second cleaning block 81 have a placement slot 82, the placement groove 82 is left and right. The movable block 83 is fixed to the wall surface of the second cleaning block 81 on both sides, and the movable block 83 is a circular columnar shape, and the two sets of the movable block 83 are attached to one side movable with each other, and the fixed block 84 is attached to each other. The internal setting of 82 has a regulating device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com