Rail car side bearing

A technology of rails and components, applied in the side bearing field of roll motion, which can solve the problems of prolonging the snaking motion events and aggravating the instability of rail cars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

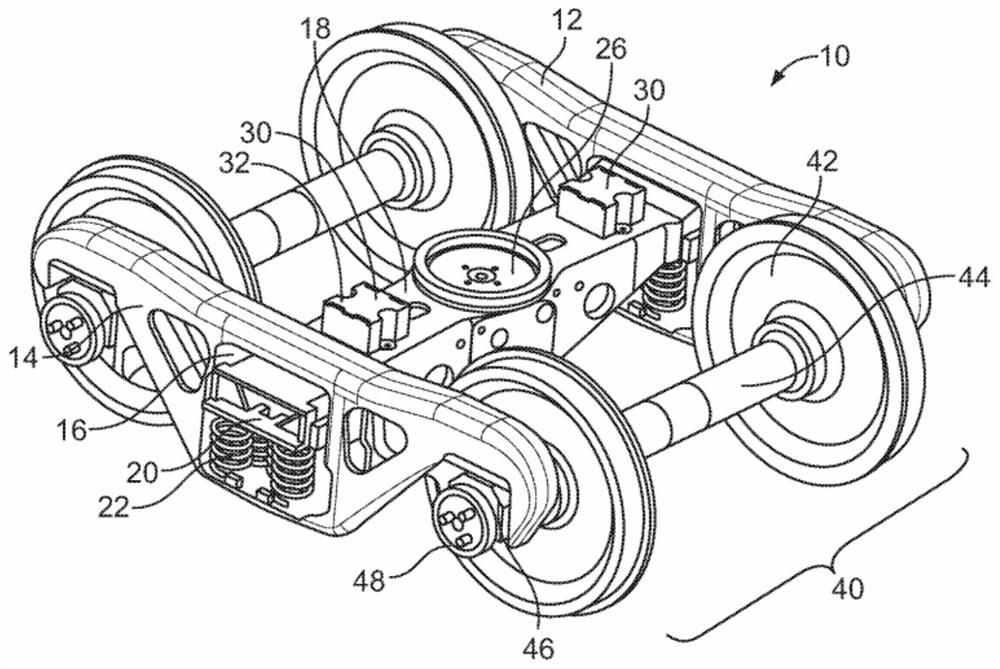

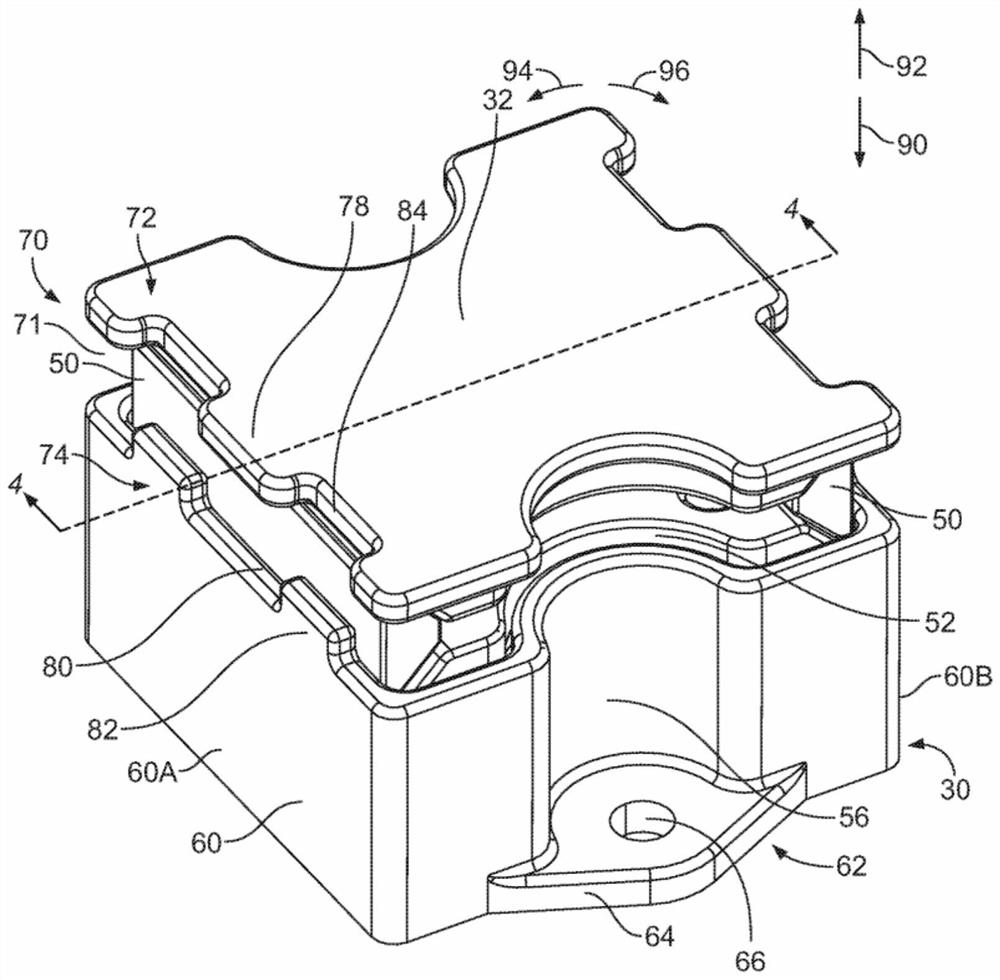

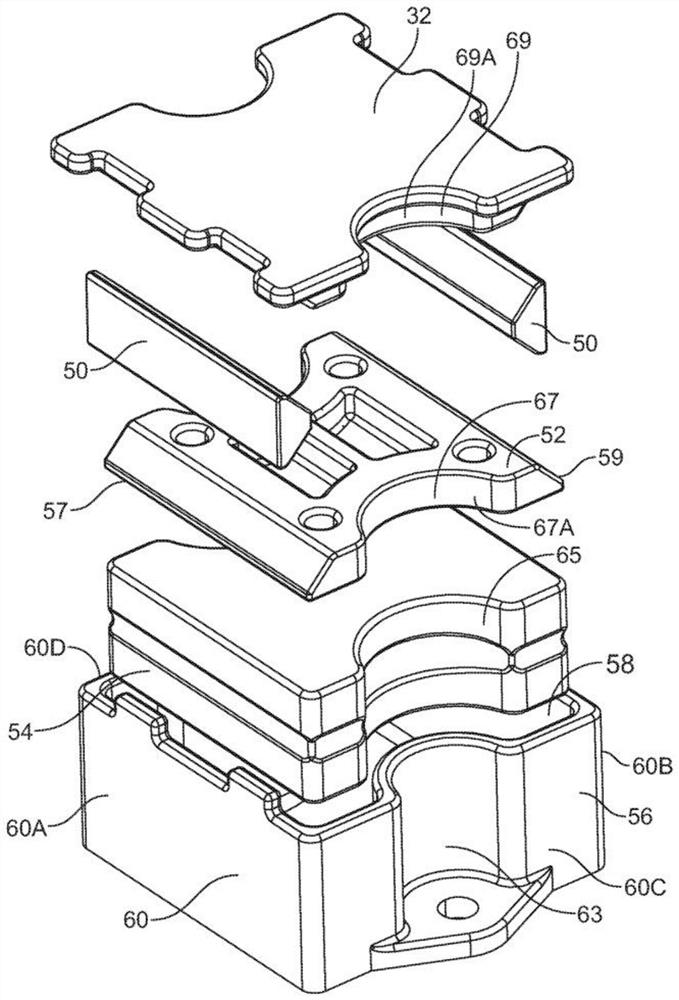

[0025] refer to figure 1 with Figure 7, a rail car truck 10 is provided that includes a bolster 18 and a pair of spaced side frames 12, 14 having an opening 16 through which the bolster 18 extends. The bolster 18 has an end portion 20 extending through the side frame opening 16 which is supported by a spring 22 . The bolster 18 includes an upper center plate 26 for receiving one of the lower core plates of the main body 23 of the railcar 25 . Railcar truck 10 includes a pair of side bearings 30 having railcar body supports such as covers 32 configured to contact bolsters 27 of railcar body 23 and to restrain railcar body 25 as it travels along the track. 23 back and forth roll motions. The cover 32 undergoes vertical reciprocating motion as the railcar body 23 rocks back and forth, and remains in constant contact with the railcar body 23 to slow the movement of the railcar body 23 . Rail car truck 10 includes one or more wheel sets 40 , each wheel set 40 including a pair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com