Operation control method and device, cooking utensil and computer readable storage medium

A technology for operation control and cooking utensils, applied in the fields of computer-readable storage media and cooking utensils, can solve the problems such as the inability to completely close the feeding opening of the cleaning cavity, the reduction of the cleanliness of the cleaning cavity, the breeding of bacteria in the cleaning cavity, etc., so as to reduce the cleaning effect. Ineffective, reducing safety issues, reducing the effect of bacterial growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

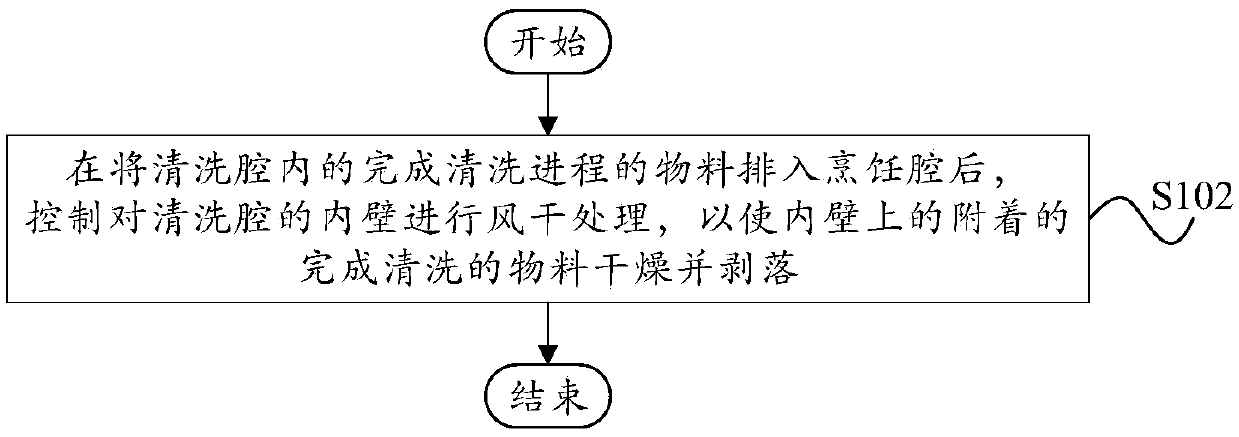

[0071] figure 1 A schematic flowchart of an operation control method according to an embodiment of the present invention is shown.

[0072] Such as figure 1 As shown, the operation control method according to the embodiment of the present invention includes: Step S102, after discharging the materials in the cleaning cavity that have completed the cleaning process into the cooking cavity, control to perform air-drying treatment on the inner wall of the cleaning cavity, so that on the inner wall The attached finished cleaning material dries and flakes off.

[0073] In this technical scheme, after the materials in the cleaning cavity that have completed the cleaning process are discharged into the cooking cavity, the inner walls (top wall, side wall and bottom wall) of the cleaning cavity are controlled to be air-dried, so that the attached inner walls can be made The cleaned material is dried, so that it is easier to enter the cooking cavity, which effectively improves the f...

Embodiment 2

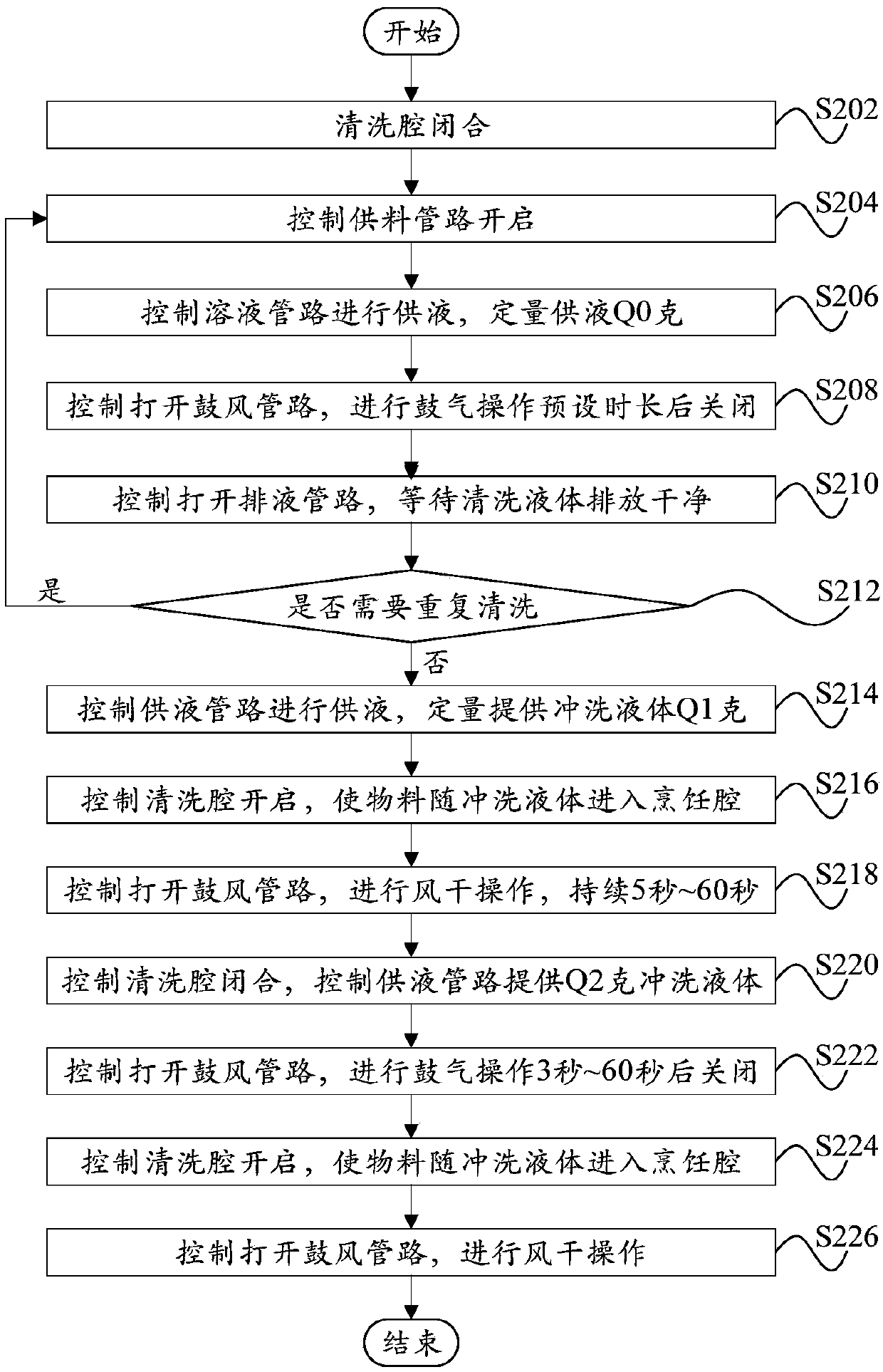

[0095] figure 2 A schematic flowchart of an operation control method according to another embodiment of the present invention is shown.

[0096] Such as figure 2 As shown, the operation control method according to the embodiment of the present invention includes: step S202, closing the cleaning chamber; step S204, controlling the opening of the feeding pipeline; step S206, controlling the solution pipeline to supply liquid, quantitatively supplying liquid Q0 grams; Step S208, control to open the blowing pipeline, and close it after performing the blowing operation for a preset period of time; Step S210, control to open the drain pipeline, and wait for the cleaning liquid to be discharged; Step S212, determine whether repeated cleaning is required, and if so, execute S204, if not, then execute step S214; step S214, control the liquid supply pipeline to supply liquid, quantitatively provide Q1 g of flushing liquid; step S216, control the opening of the cleaning chamber, so th...

Embodiment 3

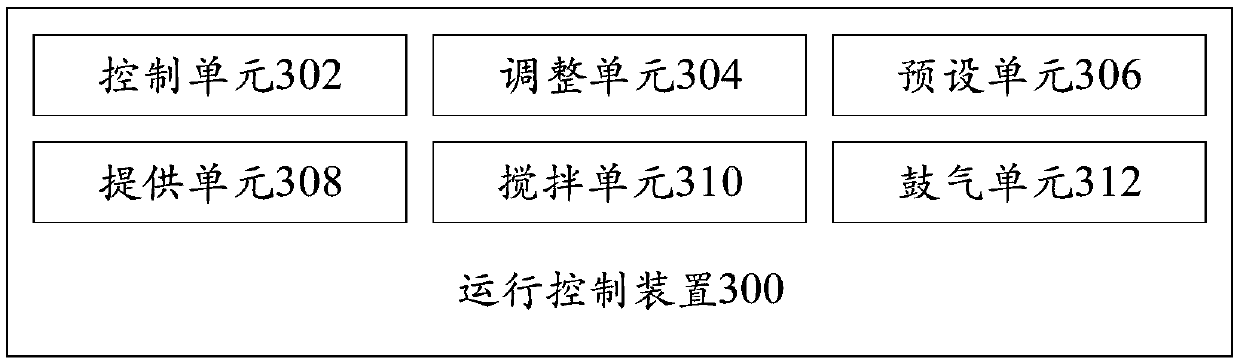

[0100] image 3 A schematic block diagram of an operation control device 300 according to an embodiment of the present invention is shown.

[0101] Such as image 3 As shown, the operation control device 300 according to the embodiment of the second aspect of the present invention includes: a control unit 302, which is used to control the cleaning process on the inner wall of the cleaning cavity after the materials that have completed the cleaning process in the cleaning cavity are discharged into the cooking cavity. Air-drying is performed to dry and peel off the adhered cleaned material on the inner wall.

[0102] In this technical scheme, after the materials in the cleaning cavity that have completed the cleaning process are discharged into the cooking cavity, the inner walls (top wall, side wall and bottom wall) of the cleaning cavity are controlled to be air-dried, so that the attached inner walls can be made The cleaned material is dried, so that it is easier to enter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com