A kind of equipment for producing gradient glare texture panel

A texture and panel technology, which is applied in the field of equipment for producing gradient glare texture panels, can solve the problems of small visual impact, achieve high visual impact, diverse visual effects, and reduce misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

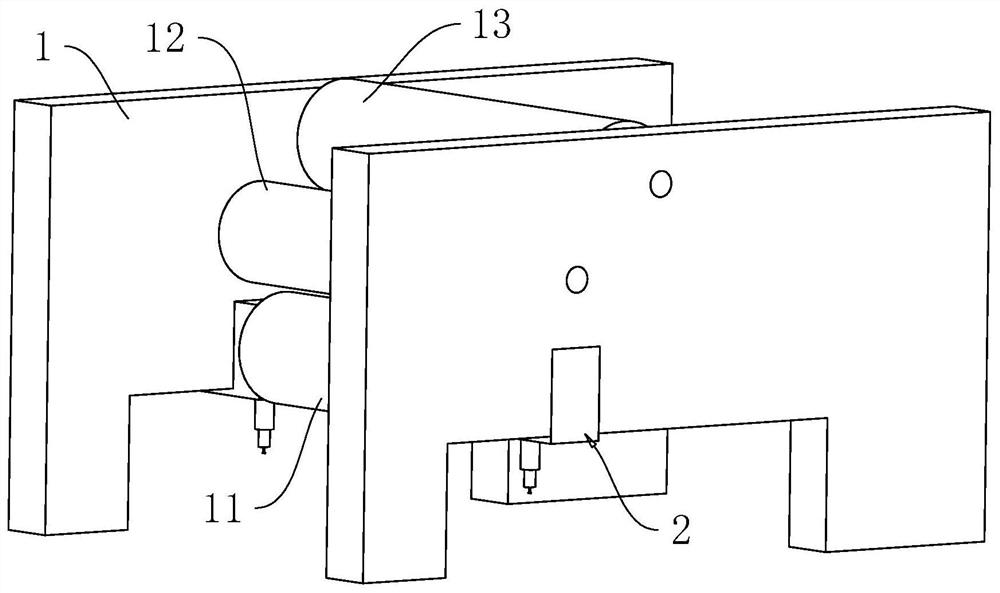

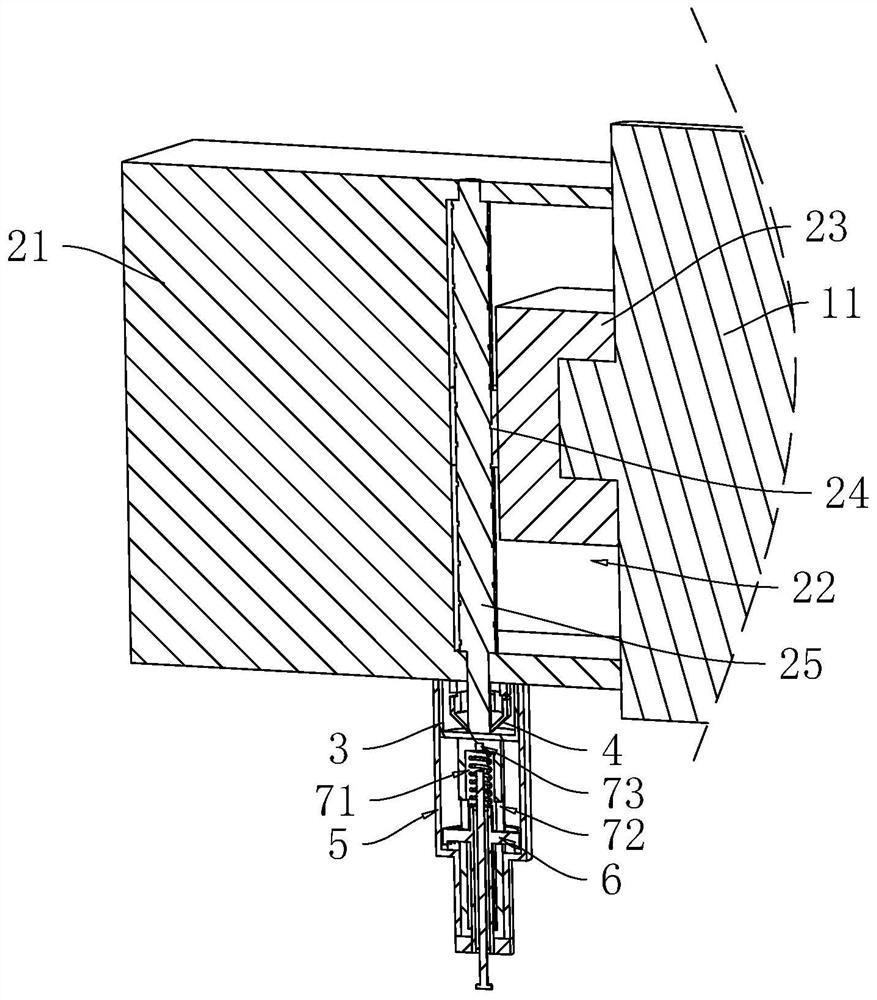

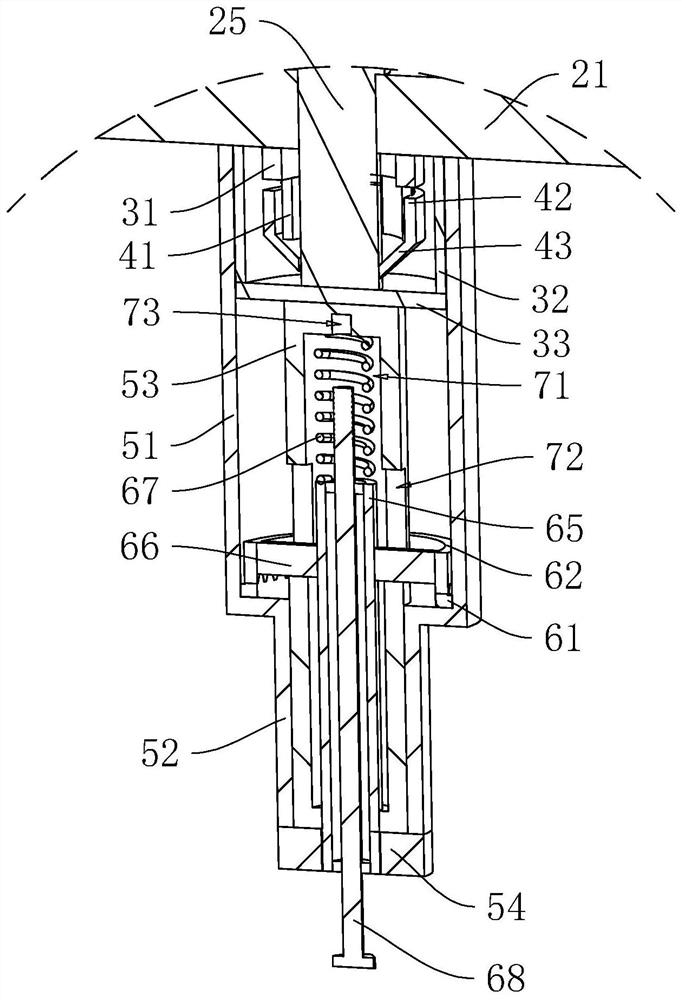

[0053] Attached to the following Figure 1-4 This application will be described in further detail.

[0054] The embodiment of the present application discloses a production process of a gradient glare textured panel.

[0055] A production process of a gradient glare textured panel includes the following process steps:

[0056] S1, pre-treatment, namely processing the transparent substrate to obtain the blank to be printed. The specific process of pretreatment is:

[0057] S11, open the material, carry out CNC cutting after the transparent base material is increased, and the allowance is 0.1 mm to obtain a rough blank, wherein the transparent base material can be tempered glass, or it can be conventional transparent such as PC and PMMA composite sheet substrate.

[0058] S12, fine carving, use a fine carving machine to grind the rough blank obtained in step S1, remove the allowance set in step S11, and perform chamfering and drilling on the rough blank according to the desi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com