A kind of modified asphalt compatibilizer and preparation method thereof

A technology of modified asphalt and compatibilizer, which is applied in the direction of building components, building insulation materials, construction, etc., can solve the problems of affecting the use effect of compatibilizer, the price of oil rich in aromatic hydrocarbons is expensive, and its properties are unstable, so as to improve the storage capacity Stability, improving anti-aging ability, and reducing the effect of preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

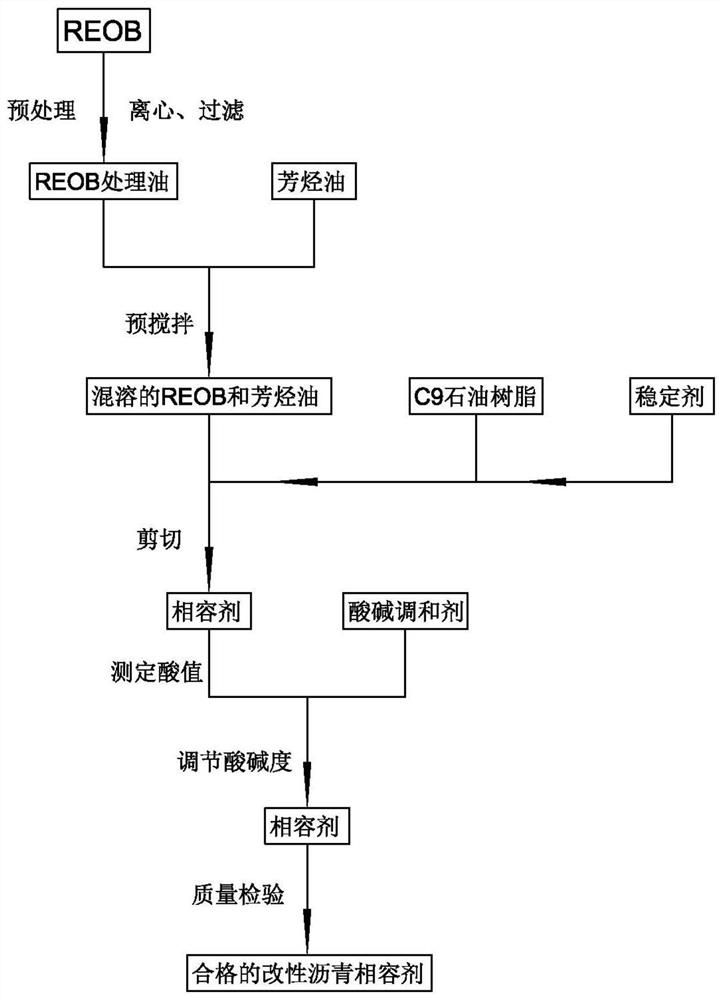

Method used

Image

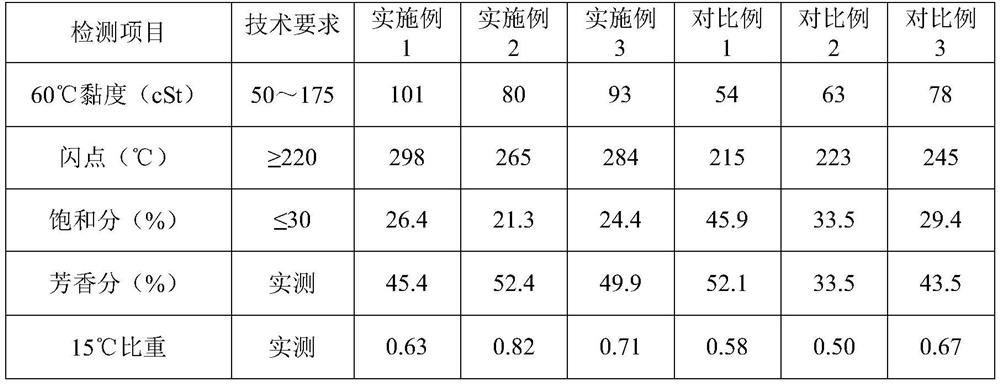

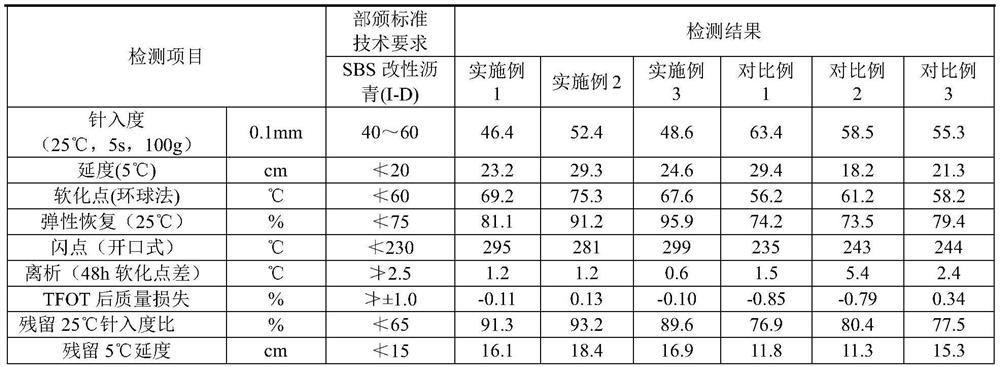

Examples

Embodiment 1

[0036] Prepare modified asphalt phase solvent, the steps are as follows:

[0037] (1) Pretreatment

[0038] Heat 5.0kg of waste engine oil residues to 160°C and perform centrifugation. The waste engine oil residues used are waste lubricating oil residues after centrifugal separation and molecular distillation process. The rotation speed is 4000r / min. The solid impurities in the bottom layer are then filtered through a screen with a pore size of 1.18mm to obtain pure waste oil residue treatment oil;

[0039] (2) Pre-stirring

[0040] Transfer waste engine oil residue treatment oil and 2.5kg aromatic oil to the high-speed shear pre-mixing system for pre-mixing to make the two fully miscible. The aromatic oil used is special aromatic oil for reclaimed rubber;

[0041] (3) cut

[0042] After pre-stirring, the miscible in step (2) is sent to the machine for high-speed shearing, and the rotating speed is 4500r / min. During the shearing process, 1.5kg C9 petroleum resin is first mi...

Embodiment 2

[0047] Prepare modified asphalt phase solvent, the steps are as follows:

[0048] (1) Pretreatment

[0049] Heat 7.0kg of waste engine oil residues to 160°C and perform centrifugation. The waste engine oil residues used are waste lubricating oil residues after centrifugal separation and molecular distillation process. The rotation speed is 4000r / min. The bottom solid impurities are separated, and then filtered through a sieve with a pore size of 1.18mm to obtain pure waste engine oil residue treatment oil;

[0050] (2) Pre-stirring

[0051] Transfer waste engine oil residue treatment oil and 1.5kg aromatic oil to the high-speed shear pre-mixing system for pre-mixing to make the two fully miscible. The aromatic oil used is special aromatic oil for reclaimed rubber;

[0052] (3) cut

[0053] After pre-stirring, the miscible in step (2) is sent to the machine for high-speed shearing, and the rotating speed is 4500r / min. During the shearing process, 1.0kg C9 petroleum resin is fi...

Embodiment 3

[0057] Prepare modified asphalt phase solvent, the steps are as follows:

[0058] (1) Pretreatment

[0059] Heat 6.0kg of waste engine oil residue to 160°C and then centrifuge. The waste engine oil residue used is the waste lubricating oil residue after centrifugal separation and molecular distillation process. The speed is 4000r / min. The bottom solid impurities are separated, and then filtered through a sieve with a pore size of 1.18mm to obtain pure waste engine oil residue treatment oil;

[0060] (2) Pre-stirring

[0061] Transfer waste engine oil residue treatment oil and 2.0kg aromatic oil to the high-speed shear pre-mixing system for pre-mixing to make the two fully miscible. The aromatic oil used is special aromatic oil for reclaimed rubber;

[0062] (3) cut

[0063] After pre-stirring, the miscible in step (2) is sent into the machine for high-speed shearing, and the rotating speed is 4500r / min. During the shearing process, 1.3kg C9 petroleum resin is first mixed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com