Method for verifying the operability of a safety valve

A safety valve, functional technology, applied in the field of checking the safety valve function, can solve the problem of not completing the manual partial stroke test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

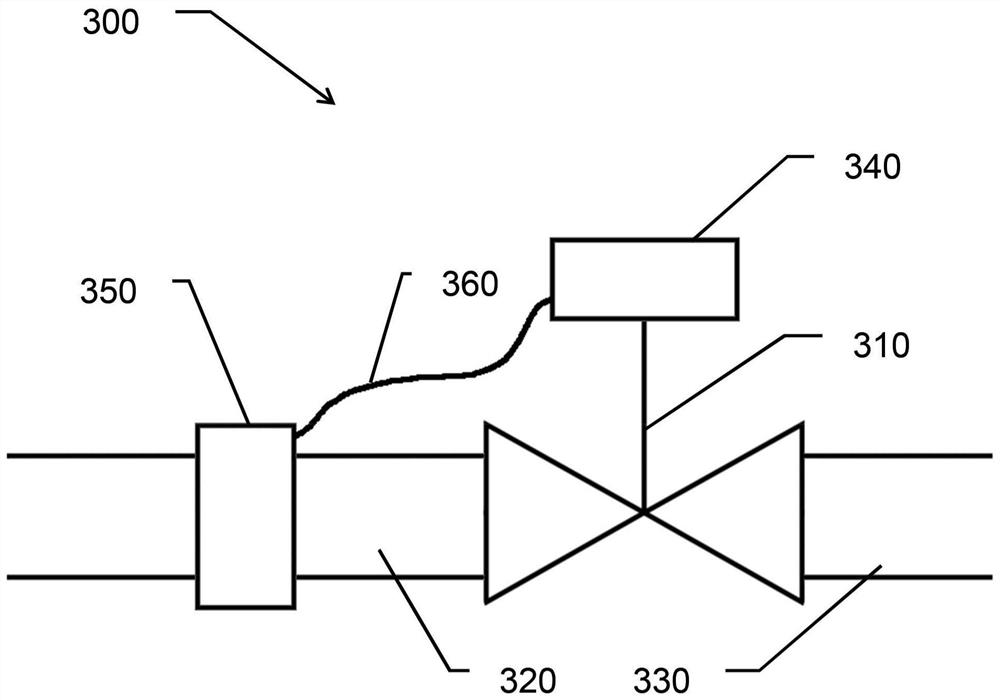

[0156] image 3 Process plant portion 300 is shown with safety valve 310 . During continuous operation of the plant, fluid process medium may be directed through section 300 or valve 310 . To this end, the valve 310 has an inlet 320 and an outlet 330 , wherein the process medium is guided into the safety valve 310 via the inlet 320 and out of the safety valve 310 again via the outlet 330 . The medium flow is controlled by means of a valve member (not explicitly shown) and a position regulator 340 which can move the valve member for this purpose. In continuous operation, the valve member is in a position that obstructs as little or as little as possible the flow of process media through the valve 310 . In the event of a disturbance, the safety valve 310 is closed by means of the position controller 340 , ie the valve member is moved by the position controller 340 into the closed position, so that process medium can no longer pass through the valve 310 .

[0157] The part 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com