High-safety locking device capable of achieving hydraulic crusher maintenance conveniently

A hydraulic crushing and locking device technology, applied in grain processing, etc., can solve problems such as inability to absorb dust, accidents of maintenance personnel, screening blockage, etc., and achieve the effect of preventing personnel from being injured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

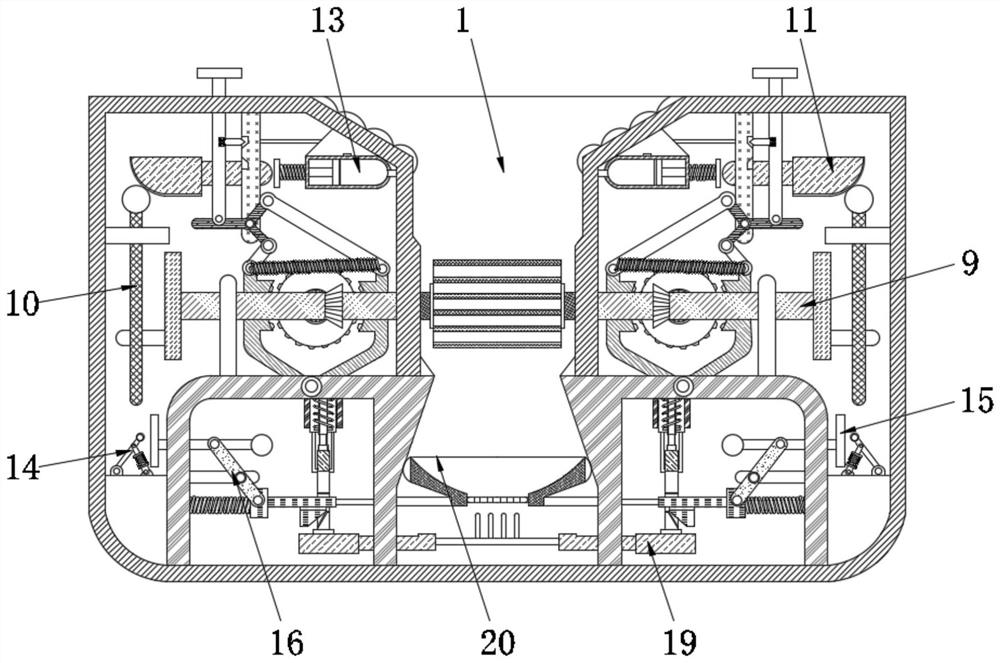

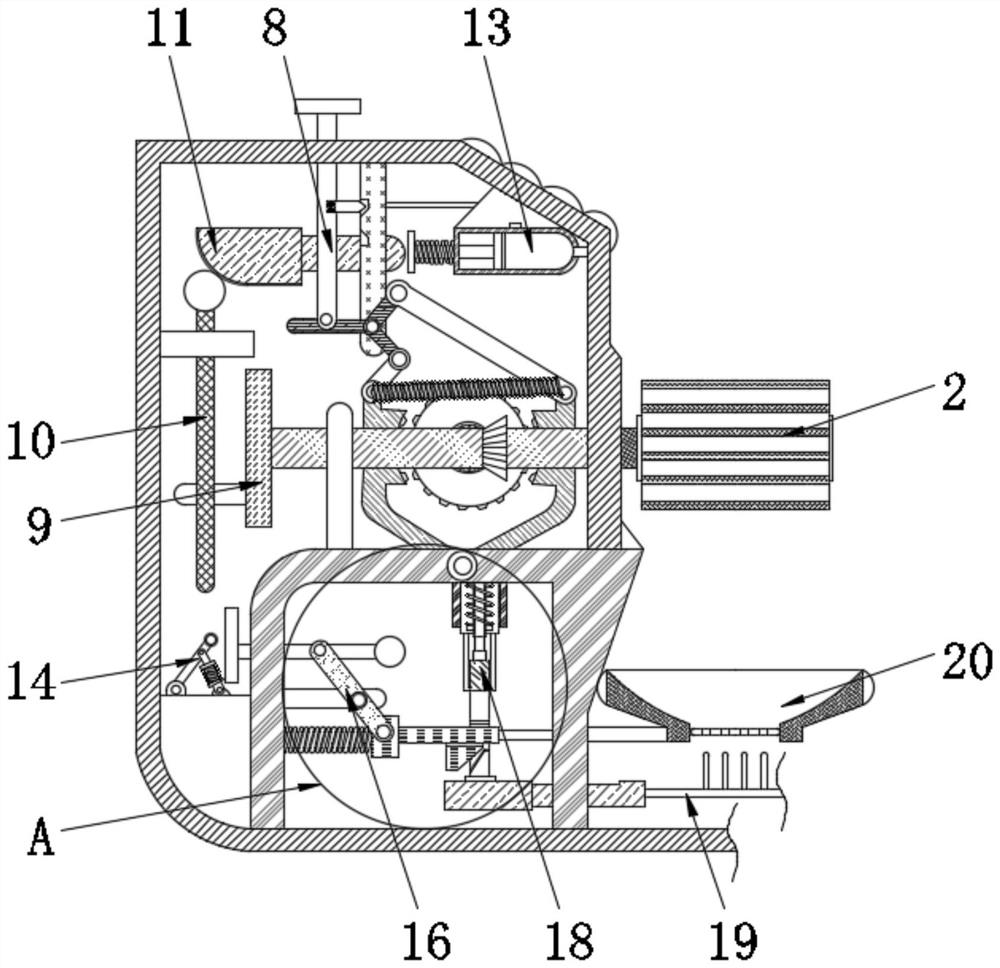

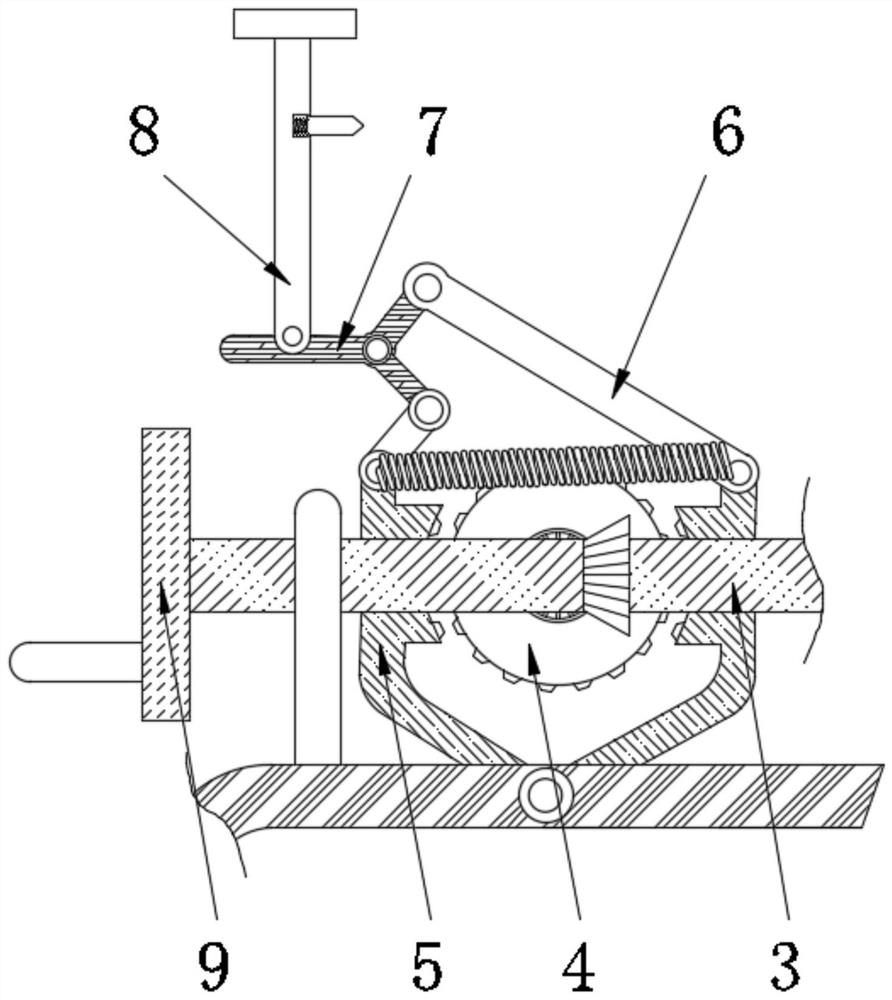

[0019] The present invention will be further described below in conjunction with accompanying drawing:

[0020] The invention provides a high-safety locking device convenient for hydraulic crusher maintenance, as attached figure 1 to attach Figure 4 Shown: includes the body 1, the body 1 is rotated and installed with the crushing roller 2, the left and right ends of the crushing roller 2 are fixedly installed with the transmission rod 3, the rear surface of the transmission rod 3 is engaged with the disc 4, and the left and right sides of the disc 4 Both are provided with clamping plates 5, and the connection between the front surface of the disc 4 and the transmission rod 3 is provided with a corresponding bevel gear, and the left and right sides of the transmission rod 3 and the inner wall of the clamping plate 5 are all provided with tooth blocks. A spring is fixedly connected between the adjacent clamping plates 5, and the bottom ends of the adjacent clamping plates 5 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com