Automatic indentation and automatic film covering machine

A laminating and automatic technology, applied in the direction of machining/deformation, etc., can solve the problems of the overall volume increase of the laminating machine, the increase of the cost, and the inability of the laminating machine to use the automatic paper output function of the creasing machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

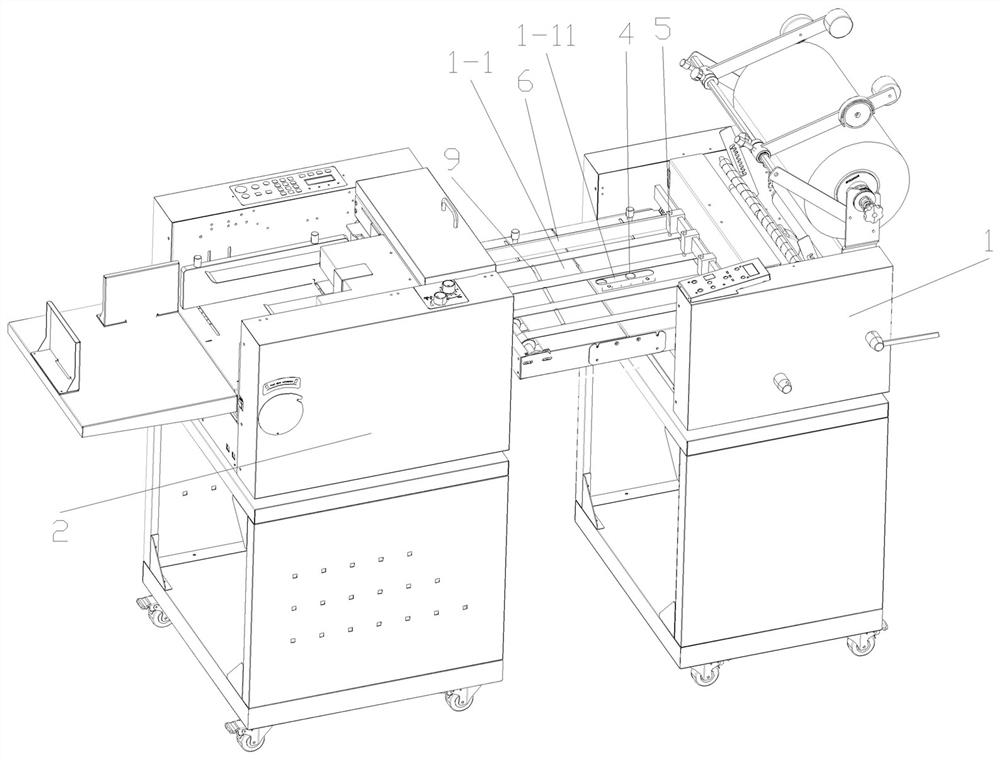

[0031] Such as figure 1 As shown in , the machine of automatic creasing and automatic laminating of the present invention comprises laminating device 1, creasing device 2 and paper sensor 4, and laminating device comprises paper feeding platform 1-1 and laminating unit, and paper feeding platform 1 -1 The paper is conveyed by conveyor belt transmission, and the laminating unit is used for laminating the paper. The middle part of the table surface of the paper feeding table 1-1 is provided with a chute 1-11 along the paper feeding direction, and the paper sensor 4 is set on the chute In 1-11, the paper sensor 4 can slide in the chute 1-11 to adjust the position, and the paper sensor 4 is used to monitor whether there is paper at the monitoring position directly above it on the paper feeding table 1-1; creasing device 2 Including paper feeding unit, creasing unit, paper output unit, creasing mode circuit, automatic lamination mode circuit and mode selection structure, paper feed...

Embodiment 2

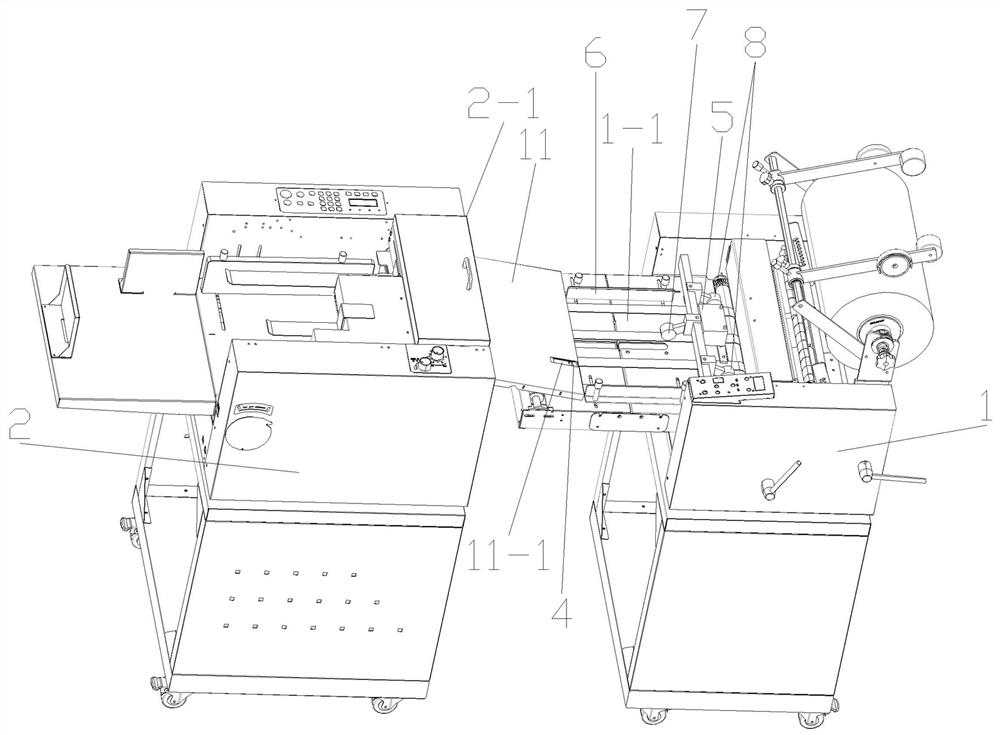

[0037] Such as figure 2 As shown in , the difference between the automatic creasing and automatic laminating machine of this embodiment and embodiment 1 is that the paper outlet 2-1 of the paper outlet unit of the creasing device 2 is provided with an inclined paper guide plate 11, and the paper guide plate 11 It is used to connect the paper feeding platform 1-1 of the laminating device to the outside. The paper sent out from the paper outlet 2-1 slides to the paper feeding platform of the laminating device through the paper guide plate 11. Both sides of the paper guiding plate 11 are hinged on the on the housing of the indentation device 2, and use screws to tighten and lock it. After the screws are loosened, the paper guide plate 11 can rotate around the hinge point. Height adjustment, the angle of inclination of the paper guide plate 11 can also be adjusted according to the paper feed rate, paper feed angle and position requirements of the paper falling on the paper feedin...

Embodiment 3

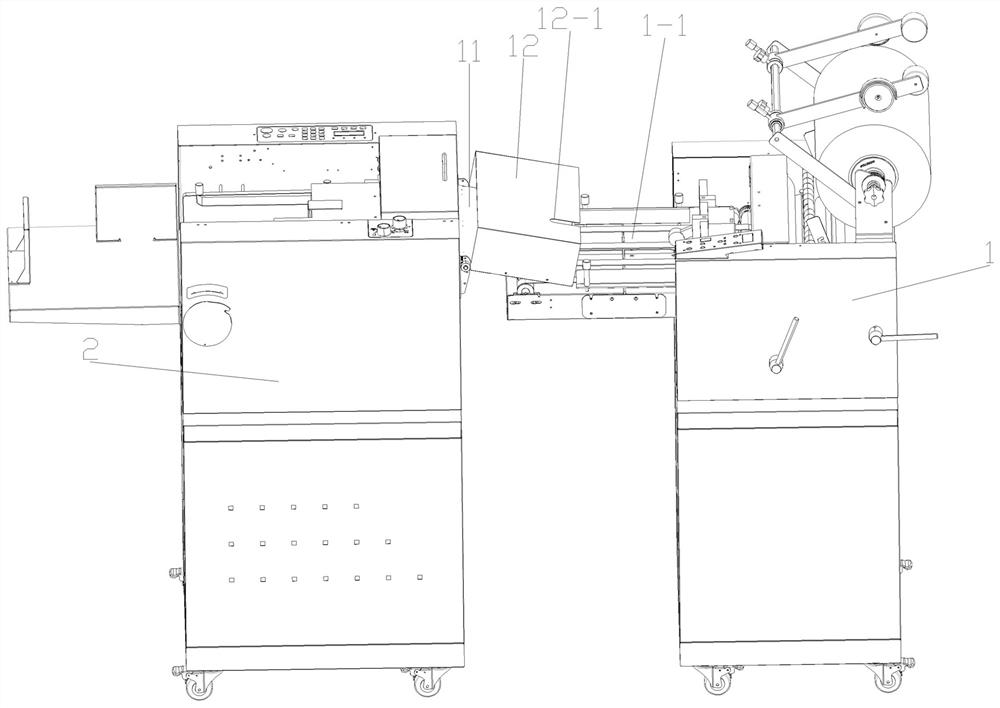

[0042] The difference between the automatic creasing and automatic laminating machine of this embodiment and embodiment 2 is that the paper guide plate 11 can also be provided with side gauges or guide grooves or guide covers that limit and guide the paper, side gauges or guide grooves or The guide cover defines the sliding passage of the paper on the paper guide plate 11 . Such as image 3 As shown, the paper guide plate 11 is provided with a guide cover 12, and the guide cover 12 covers the paper path of the paper guide plate 11, which can avoid the paper deviation or turning up caused by the blowing of the fan or blower in the use environment, so that The design is more conducive to automatic paper feeding, suitable for unmanned operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com