Automatic paper taking machine

A paper machine and automatic technology, which is applied in the direction of sending objects, thin material handling, transportation and packaging, etc., can solve the problems of high cost, high requirements on paper characteristics, and easily damaged paper, so as to reduce product cost and maintenance cost and avoid The effect of secondary finishing process and simple machine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

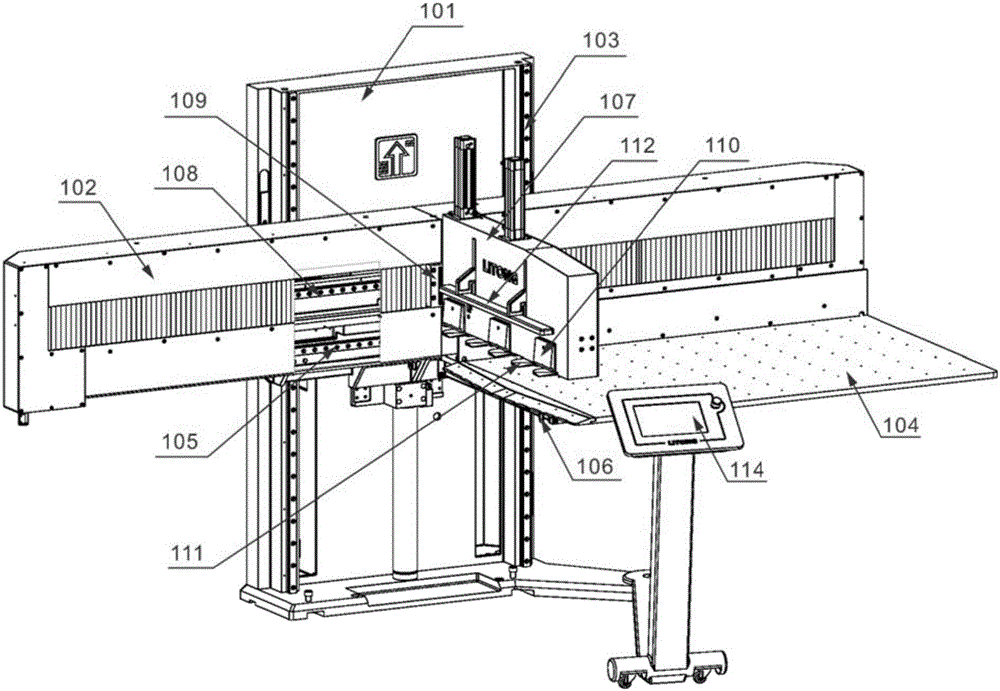

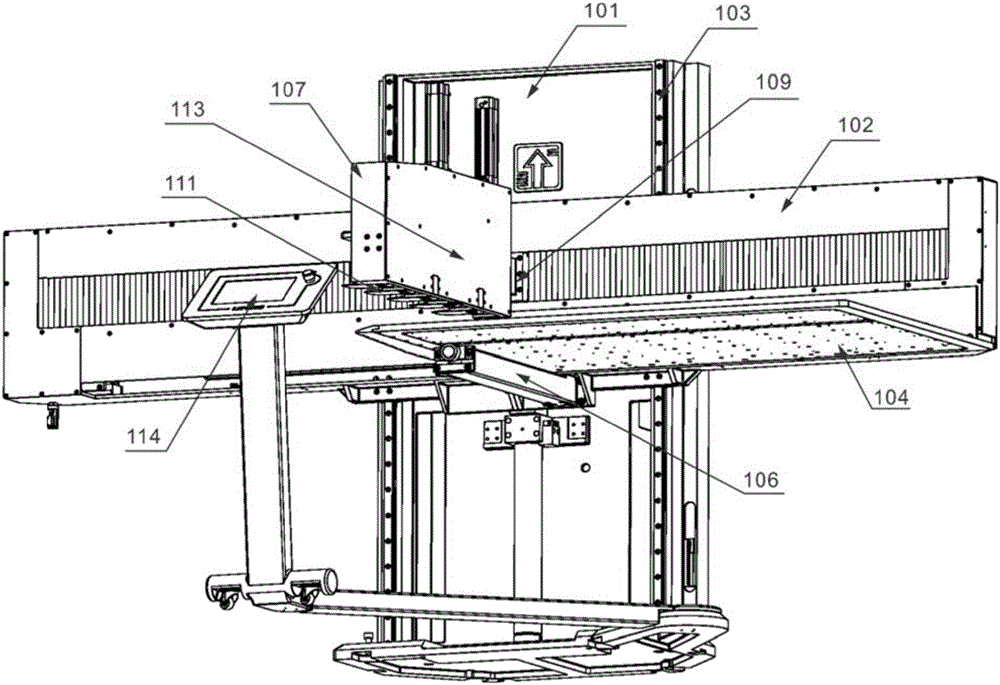

[0024] see figure 1 ,with figure 2 : The present invention mainly comprises fuselage 101, crossbeam 102, crossbeam lifting guide mechanism 103, air cushion workbench 104, air cushion workbench translation guide mechanism 105, air cushion workbench front support 106, mechanical arm 107, mechanical arm translation guide mechanism 108, mechanical Arm lifting guide mechanism 109, paper-fetching board 110, retractable paper-fetching plectrum 111, paper-feeding presser 112, mechanical arm pushing back board 113 and control panel 114.

[0025] The crossbeam 102 can move up and down along the beam lifting guide mechanism 103 under the action of its driving mechanism; Under the action of its lifting and translation drive mechanism, it can move up and down and left and right translation along the manipulator lifting guide mechanism 109 and the manipulator translation guide mechanism 108 respectively.

[0026] The initial position of paper machine of the present invention is as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com