Material belt film sticking machine

A film laminating machine and material tape technology, applied in the field of stamping and forming material belt processing equipment, can solve problems such as low efficiency and unstable film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

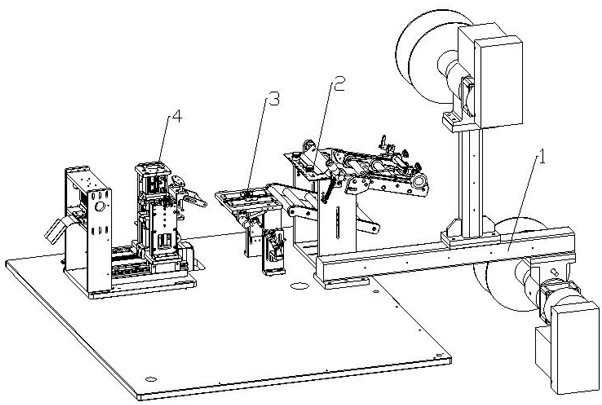

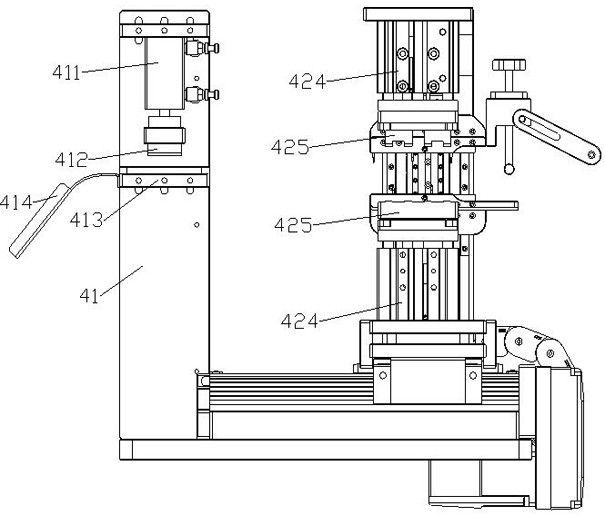

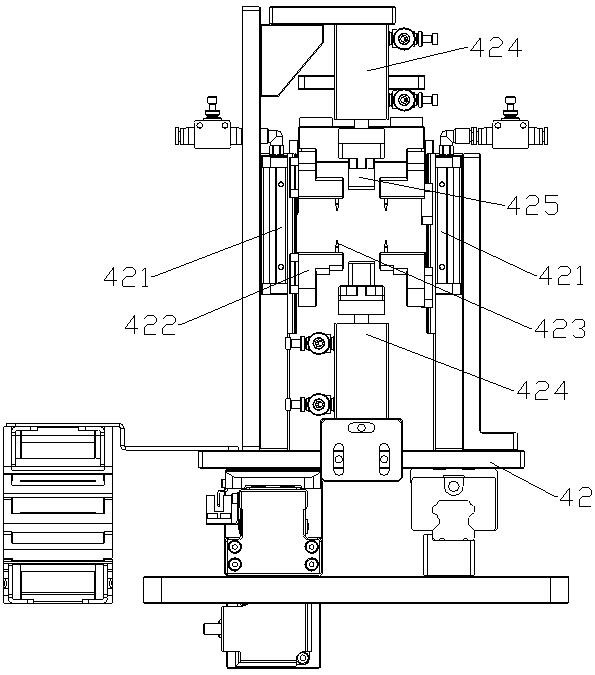

[0018] Such as Figure 1 to Figure 4 As shown, a tape laminating machine includes a film feeding module 1, a film stripping module 2, a material guide module 3 and a film pasting module 4 arranged sequentially along the advancing direction of the tape; the film stripping module 2 Including a film peeling support 21; the film peeling support 21 is provided with two sets of guide shafts and stripping knives 211; the film sticking module 4 includes a horizontal drive device, a film sticking base 42 and a positioning cylinder 421; the film sticking base 42 Set on the horizontal drive device; the positioning cylinder 421 is set on the film base 42 through a bracket; the positioning block 421 is provided with a positioning block 422; the positioning block 422 is provided with a positioning pin 423; the film base 42 Two film-sticking cylinders 424 are also arranged on it; the piston rods of the two film-sticking cylinders 424 are all provided with a film-sticking block 425; when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com