Seamless connection track capable of being bent horizontally

A technology of seamless connection and rail connection, which is applied in the direction of rail system, load suspension components, transportation and packaging, etc., and can solve problems such as unstable operation, derailment, and large gaps of rail traveling equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

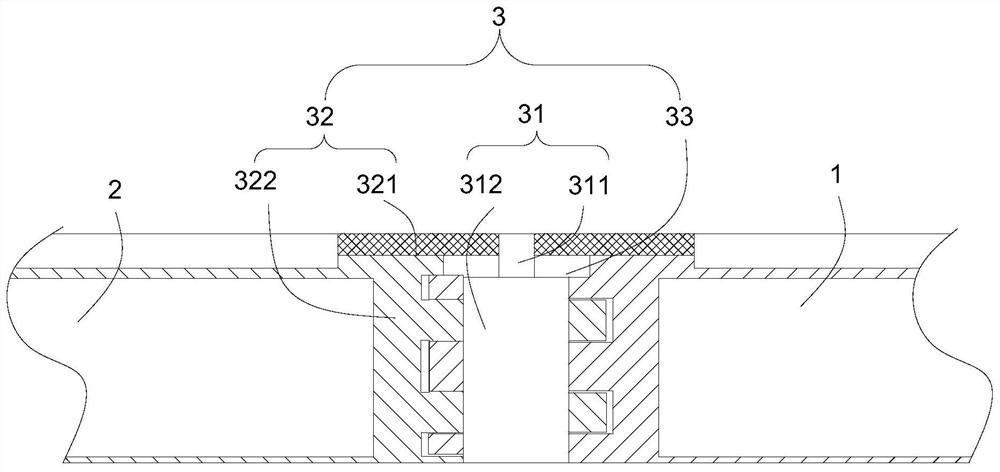

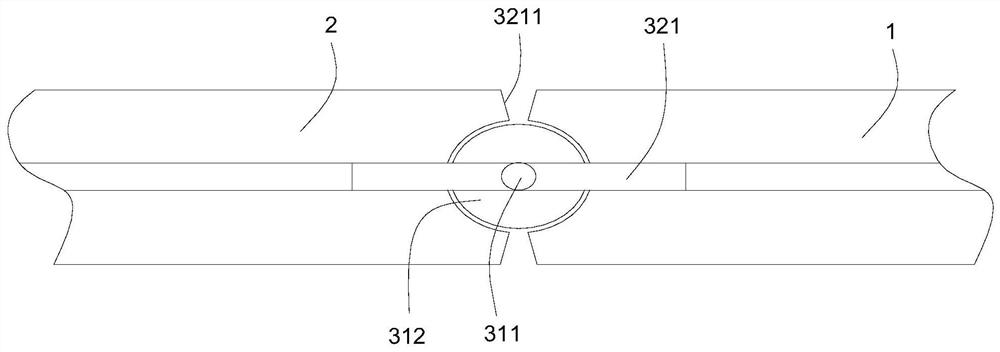

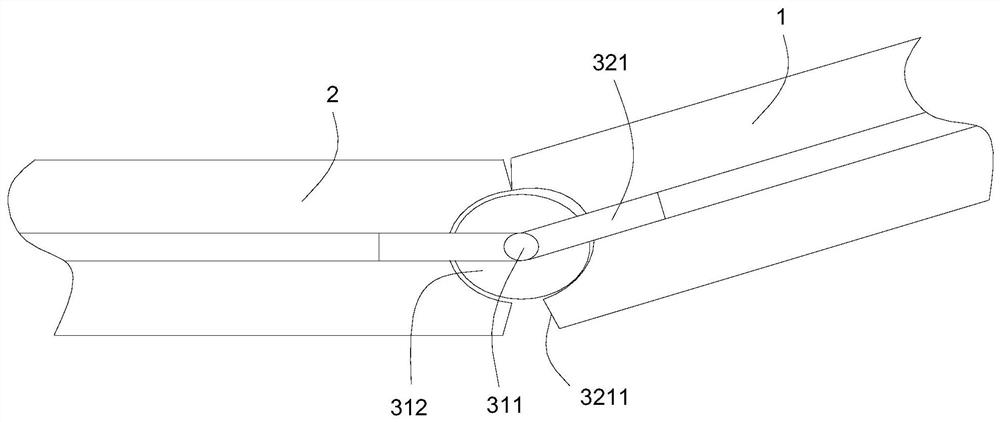

[0032] Example: such as Figure 1 to Figure 5 As shown, a seamlessly connected track that can be bent horizontally includes a front track 1 , a rear track 2 and a connecting structure 3 connecting the front track 1 and the rear track 2 . The connection structure 3 includes a hinge device 31 and a connection device 32 . The hinge device 31 includes a first hinge column 311 and a second hinge column 312, the cross-sectional area of the second hinge column 312 is larger than the cross-sectional area of the first hinge column 311, and the first hinge column 311 is set At the center of the upper end surface of the second hinge column 312 . The connecting device 32 includes two connecting rails 321 and two connecting beams 322 . The front side of the first hinge column 311 is connected to the front track 1 through a connecting rail 321 , and the rear side of the first hinge column 311 is connected to the rear track 2 through another connecting rail 321 . The two connecting be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com