Anti-wrinkle rapid cloth paving device

An anti-wrinkle and fast technology, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of affecting the cutting processing accuracy, easy wrinkling of fabrics, and low flatness, so as to save manpower, spread fast and smooth high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the examples and drawings, but the embodiments of the present invention are not limited thereto.

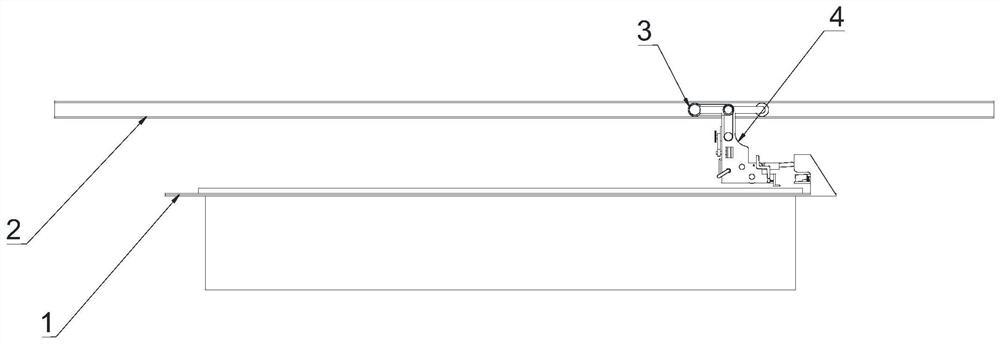

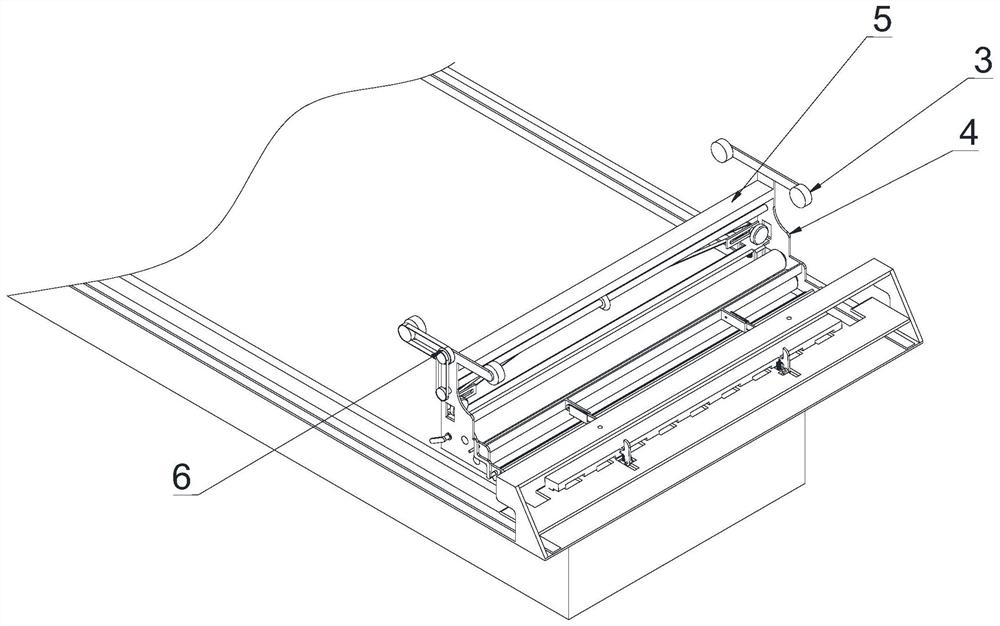

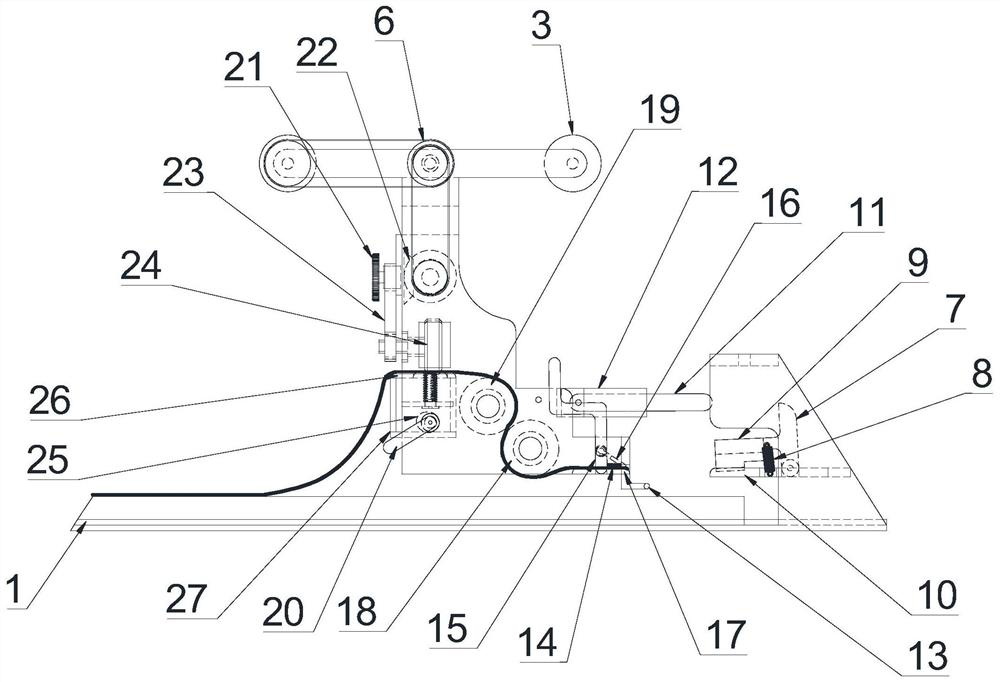

[0026] see Figure 1-Figure 9 , the anti-wrinkle rapid cloth spreading device of this embodiment includes a sliding frame, a cloth pulling and discharging mechanism, a cloth leveling mechanism and a positioning and tensioning mechanism. The sliding frame is arranged above the platform 1, and the sliding frame can be moved along the The length direction of the platform 1 performs reciprocating sliding movement, the pulling cloth discharging mechanism and the cloth leveling mechanism are both arranged on the sliding frame, and the positioning and tensioning mechanism is fixedly arranged at one end of the platform 1; wherein, the pulling cloth The discharge mechanism includes a cloth clamping assembly for clamping the front end of the cloth and a cloth clamping control mechanism for controlling the clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com