Front mounted vehicle spreader

A spreader and front-mounted technology, applied in the field of front-mounted vehicle spreaders, can solve problems such as hidden safety hazards, difficult quality assurance, and a large amount of labor, so as to improve construction quality, improve work efficiency, facilitate maintenance and The effect of overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

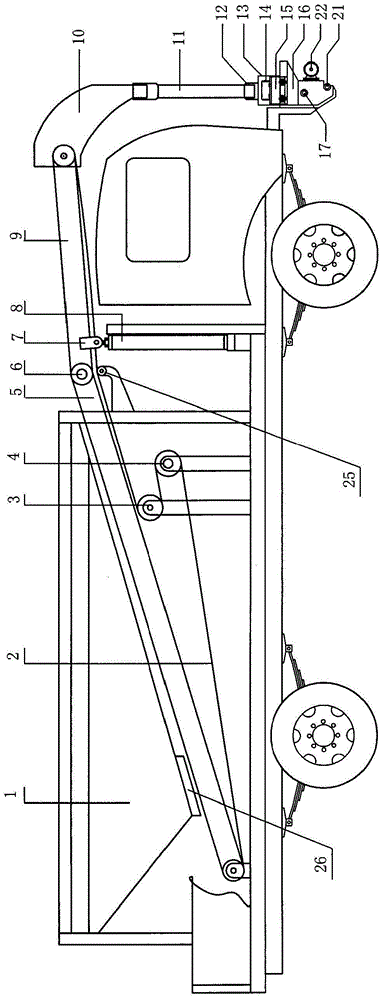

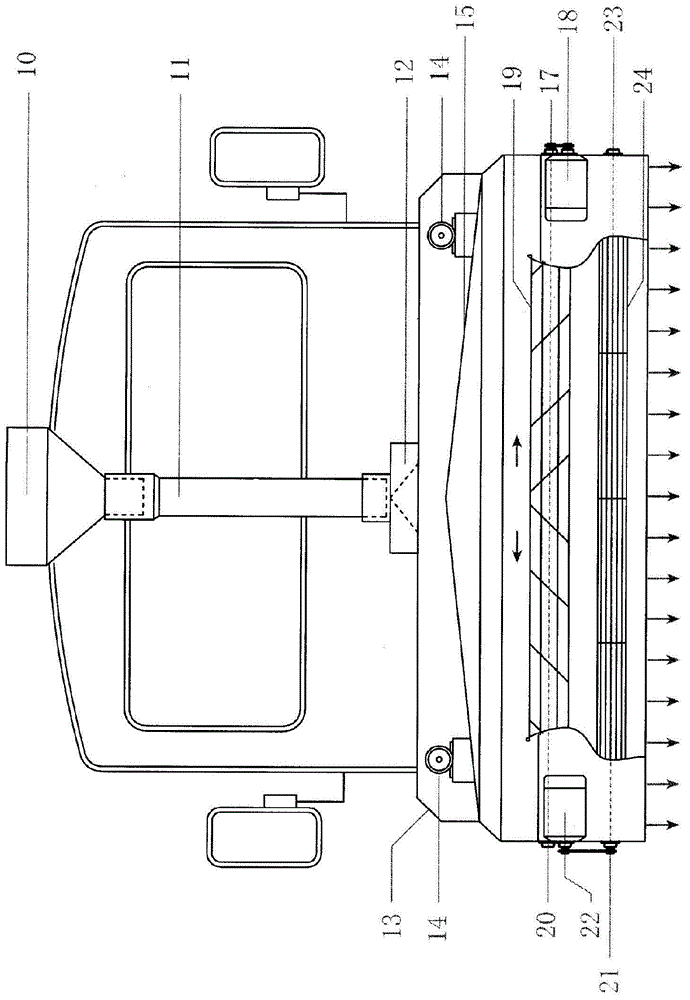

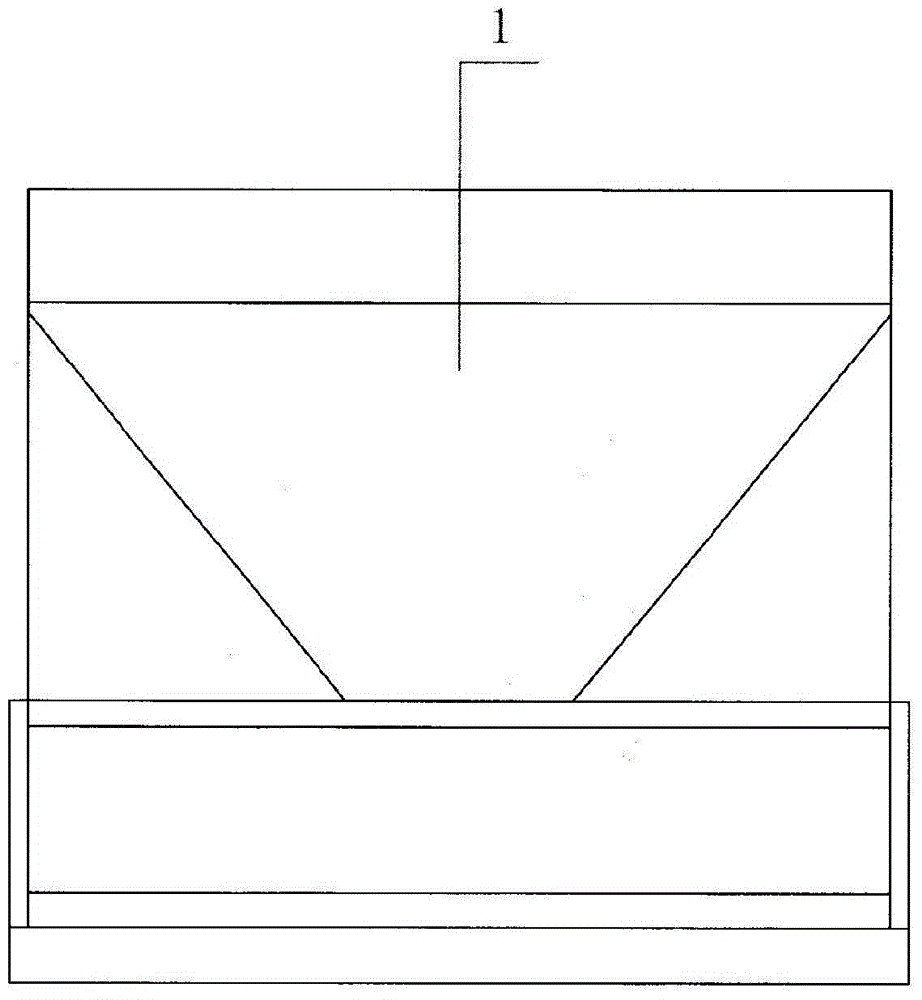

[0015] Figure 1~4 Middle, 1. Collection bin; 2. Conveyor belt; 3. Conveyor belt roller; 4. Conveyor belt speed regulating motor; 5. Conveyor fixed section; 6. Conveyor movable shaft; 7. Hydraulic support; 8. Hydraulic cylinder ;9. Conveyor lifting section; 10. Receiving box; 11. Unloading connecting pipe; 12. Collecting material inlet; 13. Spreader shell; 14. Vibrating speed regulating motor; 15. Vibrating screen; 16. Storage bin; 17, material distribution shaft; 18, material distribution speed regulating motor; 19, two-way material distribution spiral blade; 20, material distribution bearing seat; 21, material spreading shaft; 22, material spreading speed regulating motor; 23, material spreading Bearing seat; 24, volume control blade; 25, conveyor belt idler; 26, outlet of collecting bin.

[0016] Depend on Figure 1~4 It can be seen that this front-mounted vehicle-mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com