Precise installation method and structure for butt joint of split type jacket foundation and upper module of large offshore electrical platform

A technology of precise installation and jacket, applied in infrastructure engineering, underwater structures, assembly of wind turbines, etc. It can solve problems such as difficulty in placing receivers smoothly, inability to complete floatover, and large errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

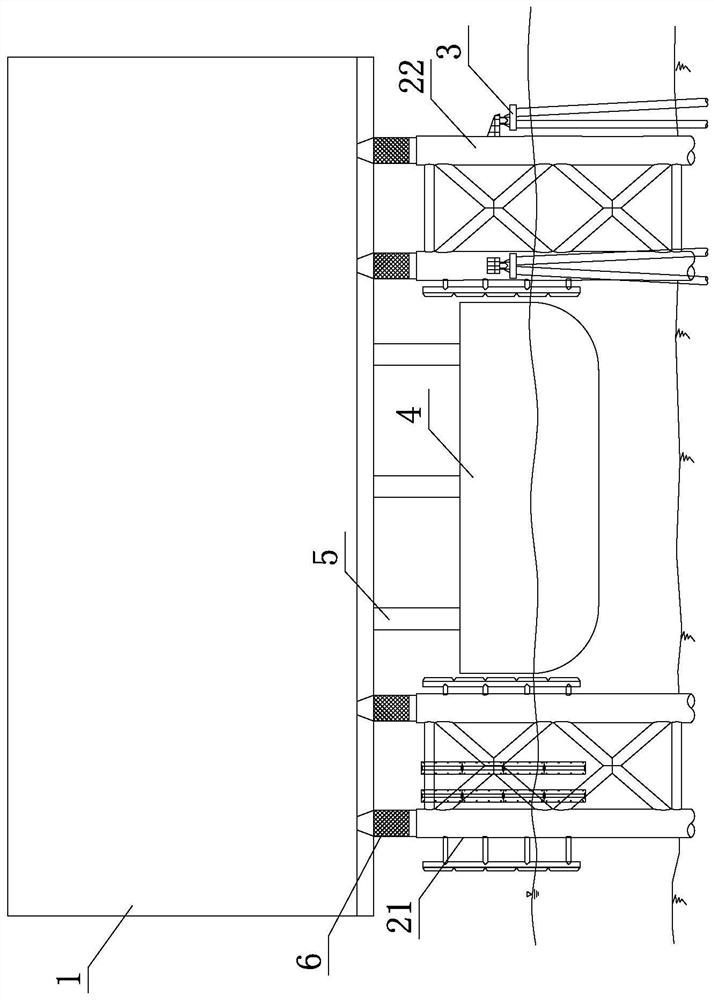

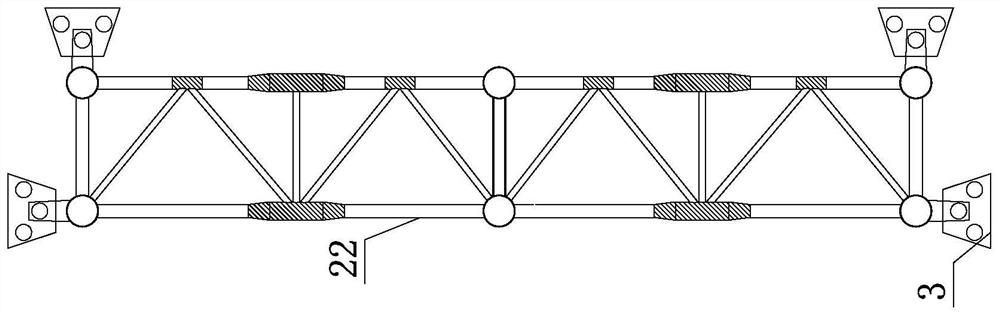

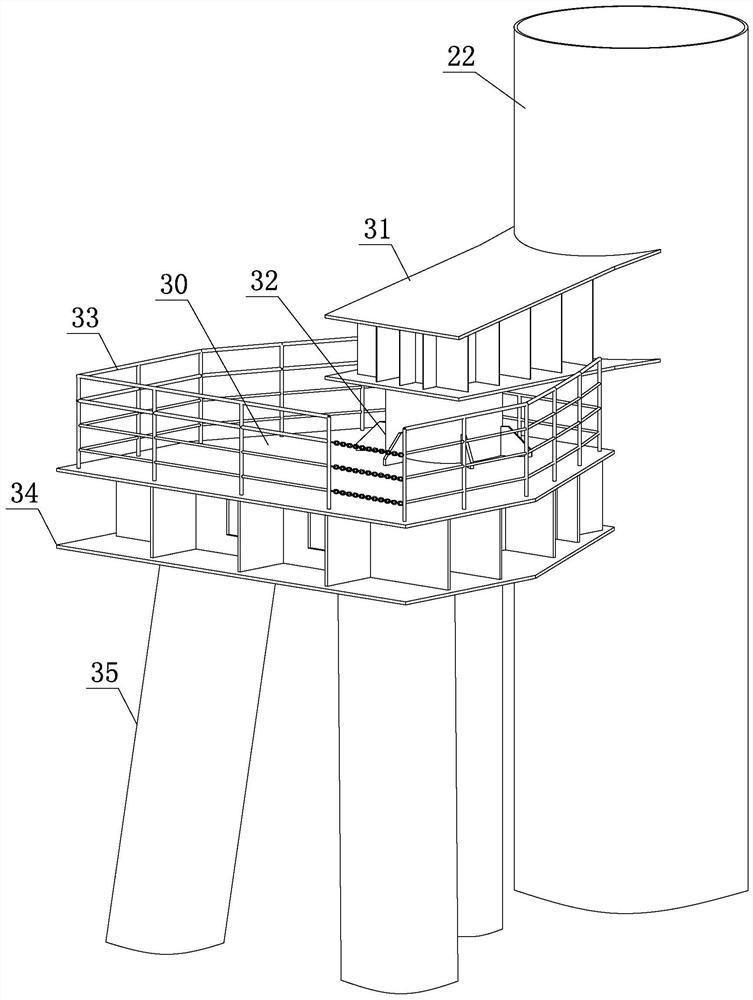

[0039] like figure 1 , 2 As shown, the large-scale offshore electrical platform adopts the precise installation method of the present invention to float and install the upper block 1 . Before installing the floatover, it needs to be hoisted in place according to the absolute coordinates of the piece jacket 21 installed first, and the position of each pile in the auxiliary platform 3 calculated according to the absolute coordinates of the piece jacket 22 installed later, the auxiliary platform 3 Arranged on the outside of the long side direction and the short side direction of the post-installation piece jacket 22, to ensure the entry and exit of the floating ship and the precise positioning of the post-installation piece jacket 22. At the same time, the plane error of the receiver of each leg coupling unit (LMU) is fed back, and the final form of the adjustable conical plate node 6 is determined, which is processed and manufactured in the onshore manufacturing plant. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com