Steel rail surface damage fine-grained image classification and detection method

A detection method and fine-grained technology, applied in image analysis, image enhancement, image data processing, etc., can solve the problems of digitalization, low automation and intelligence, low efficiency, and inability to provide predictive decision-making information for rail maintenance and repair, etc., to achieve The effect of improving driving safety and comfort and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

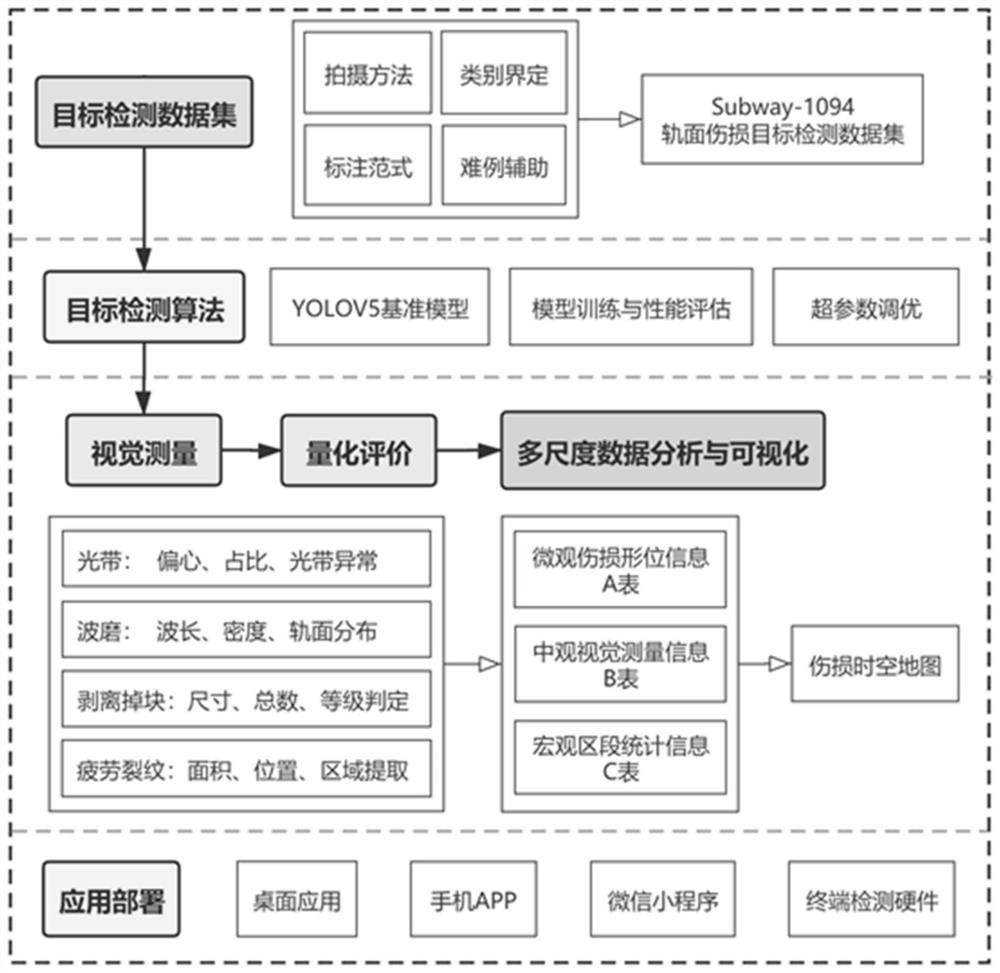

[0061] Such as figure 1 As shown, the present invention provides a fine-grained image classification and detection method for rail surface damage, including the following:

[0062] (1) Constructing a target detection dataset: A standard process for constructing a rail surface damage target detection dataset is proposed, including shooting methods, damage category definition, instance-level fine-grained target detection and labeling paradigm, and auxiliary enhancement for low-contrast difficult images method, and then proposed the Subway-1094 track surface damage target detection dataset. The data set is superior to existing data sets in terms of image quantity, image quality, damage category, labeling quality, and target density, and can drive deep learning algorithm training.

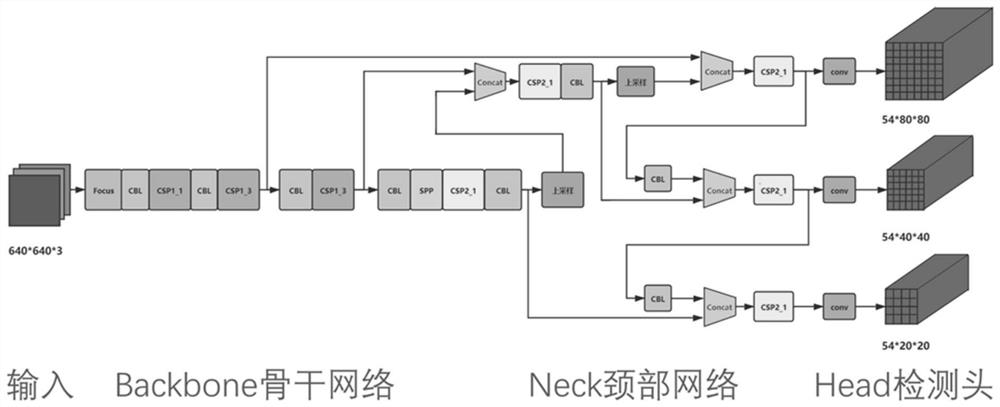

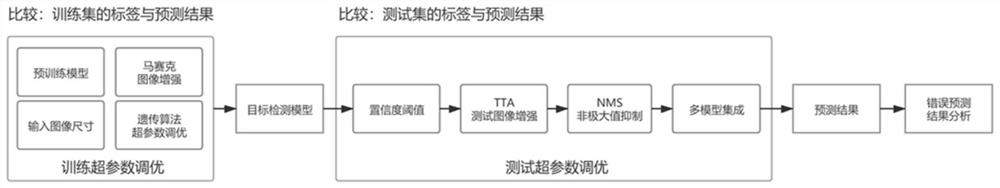

[0063] (2) Training target detection algorithm: YOLOV5 deep learning target detection algorithm is trained based on the above data set. Evaluate the recognition performance of each category, optimize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com