Adsorption type chip transfer device and chip repair device

A chip transfer and adsorption technology, used in electric heating devices, auxiliary devices, welding equipment, etc., can solve problems such as chip damage, and achieve the effect of facilitating installation operations, improving loading efficiency and loading quality, and avoiding collapse and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

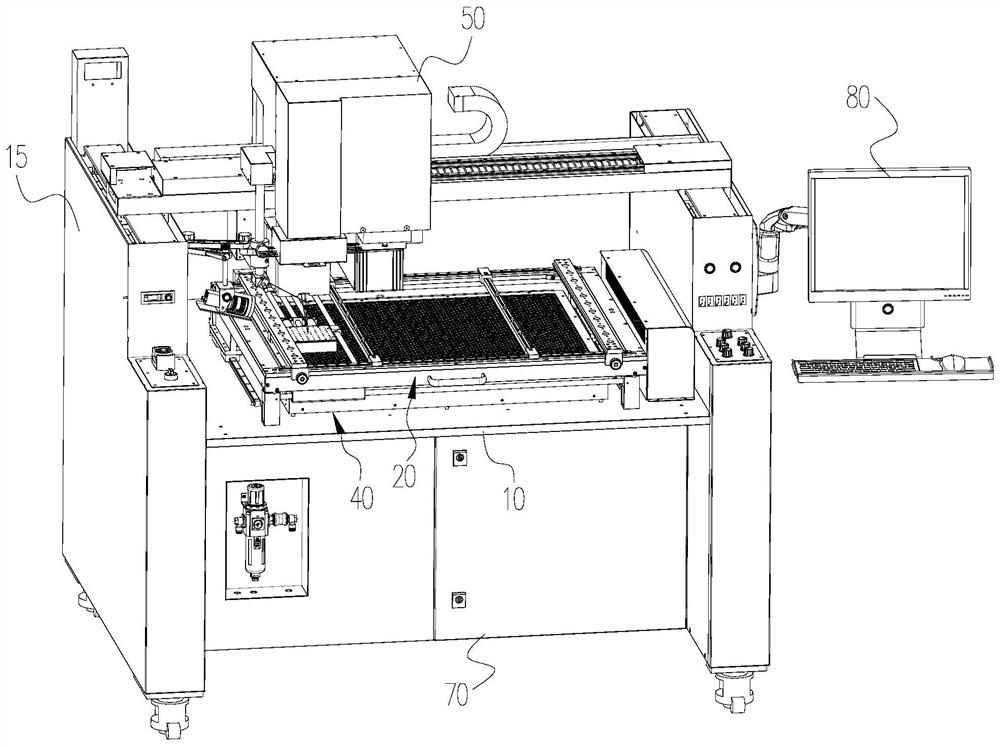

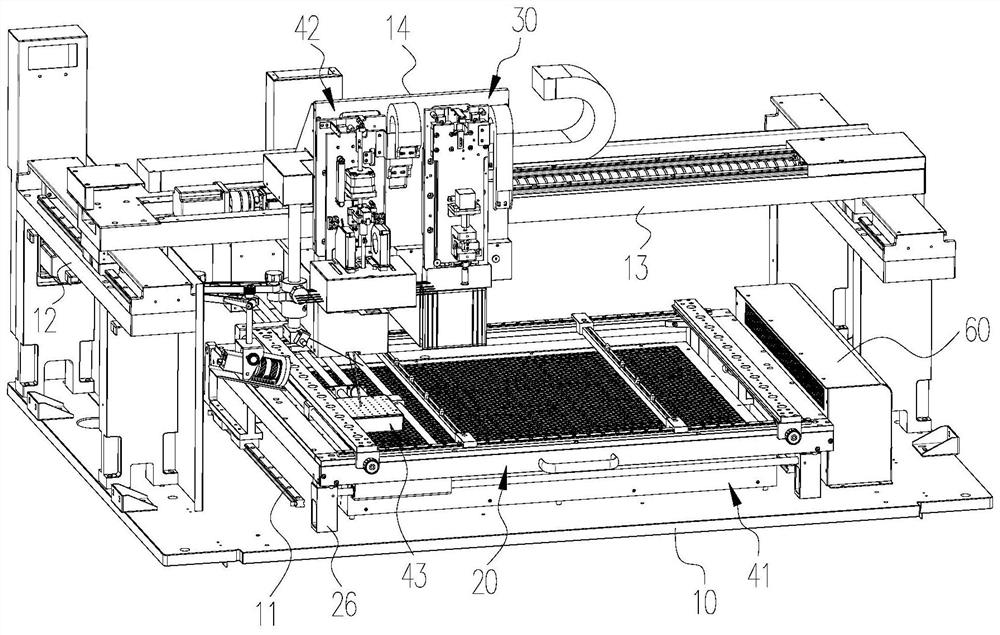

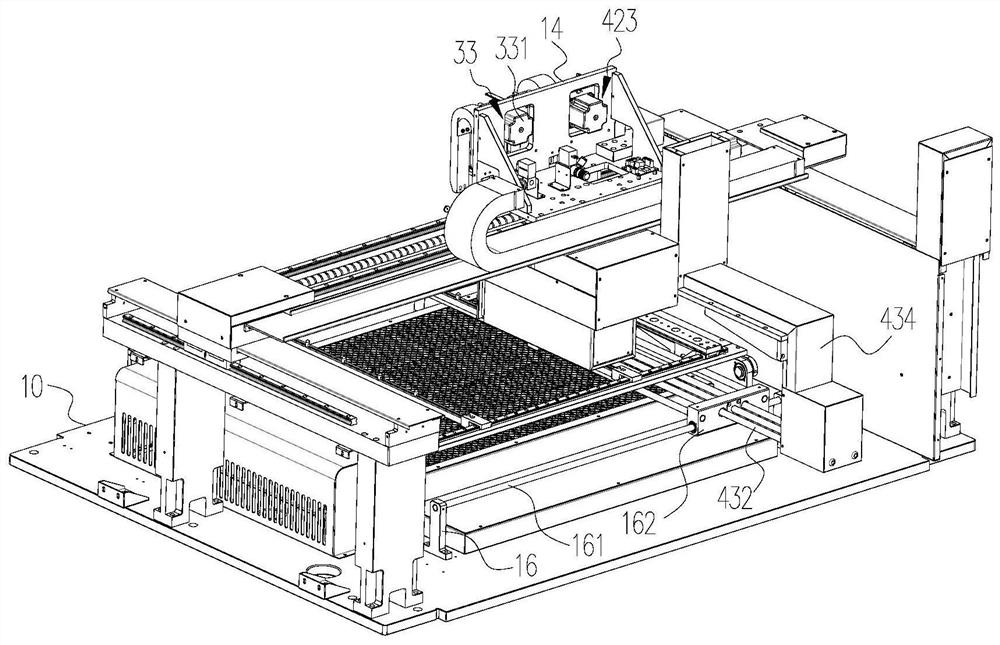

[0093] see figure 1 , figure 2 , the present invention provides a chip rework equipment for desoldering, transfer and soldering of chips, the chip rework equipment includes a machine platform 10, a stage mechanism 20 arranged on the machine platform 10 and used for placing chips, which can The adsorption type chip transfer device 30 that is movably arranged on the stage mechanism 20 and the heating device 40 installed on the machine platform 10, wherein the stage mechanism 20 is used to load a fixed circuit board, and the adsorption type chip transfer device 30 is used to transfer The chip is transferred to the mounting position of the circuit board, and the heating device 40 is used to heat the circuit board to facilitate desoldering and welding.

[0094] see Figure 4 The stage mechanism 20 includes a sliding seat 21 slidably arranged on the machine table 10, a frame 22 reversibly installed on the sliding seat 21, and a support plate 23 and a support rod slidably arranged...

Embodiment 2

[0141] see Figure 18 Embodiment 2 of the present invention provides a chip rework device. The difference between the chip rework device and Embodiment 1 is that the structure of the desoldering heating mechanism 42 of the present invention is different, specifically the structure of the heating module 424 is different.

[0142] Specifically, the heating module 424 in the second embodiment includes a hot air mixing chamber 4248 installed on the sliding plate 422, a cartridge heater 4249 installed on the top of the hot air mixing chamber 4248, and a hot air nozzle installed at the bottom of the hot air mixing chamber 4248. 4250, the cartridge heater 4249 is connected to the blower through the air pipe joint 4251. When in use, the wind generated after the fan is started is heated by the cartridge heater 4249 and enters the hot air mixing chamber 4248, and then passes through the hot air nozzle 4250 Flow to the part of the chip to be desoldered.

[0143] In addition, in order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com