Secondary packaging device and secondary packaging method of soft package battery

A technology for secondary packaging and soft pack batteries, which is applied in the direction of exhaust plug devices, battery pack components, circuits, etc., and can solve problems such as unfavorable battery quality, polluting battery outer packaging, and electrolyte splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

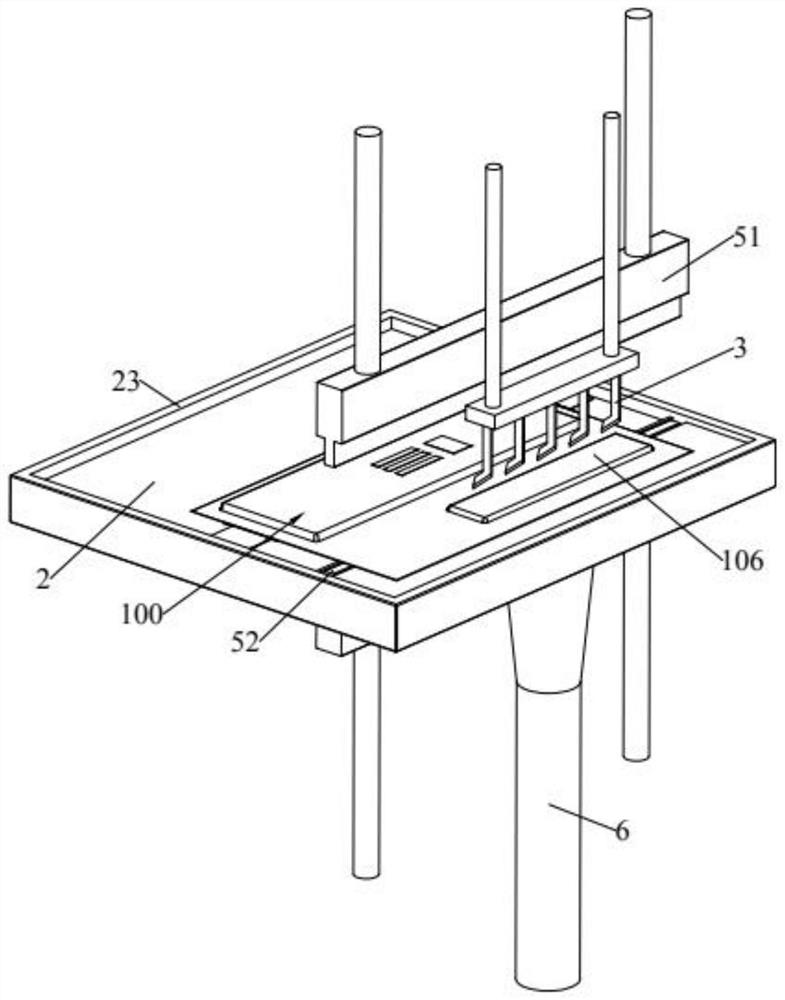

[0064] As an embodiment, the number m of vacuum holes 22 ≥ the number n of bayonets 3 and at least (m-l) positions of vacuum holes 22 correspond to bayonets 3, wherein, l is the number of empty grooves.

[0065] It can be understood that the corresponding position means that the bayonet 3 can extend into the vacuum hole 22 during the process of puncturing the air bag 106 .

[0066] In order to facilitate secondary packaging of the battery 100, such as Figure 2 to Figure 4 As shown, the secondary packaging device of the pouch battery in this embodiment also includes a packaging mechanism 5, and the packaging mechanism 5 includes an upper sealing head 51, a lower sealing head 52, a second lifting driver (not shown) and a third lifting The driver (not shown), the upper head 51 is disposed in the housing 1 and above the tray 2 . The lower sealing head 52 is disposed in the casing 1 and is located below the upper sealing head 51 , and the lower sealing head 52 runs through the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com