A pcb board cleaning transfer device

A transfer device and PCB board technology, applied in the direction of cleaning/polishing of conductive graphics, secondary treatment of printed circuits, etc., can solve problems such as corrosion, health damage of staff, etc., to reduce contact, improve labor efficiency, and prevent falling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] The specific implementation is described as follows:

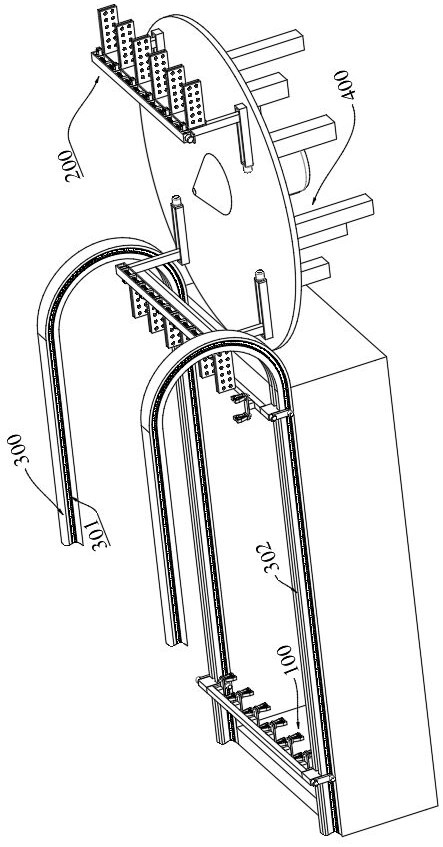

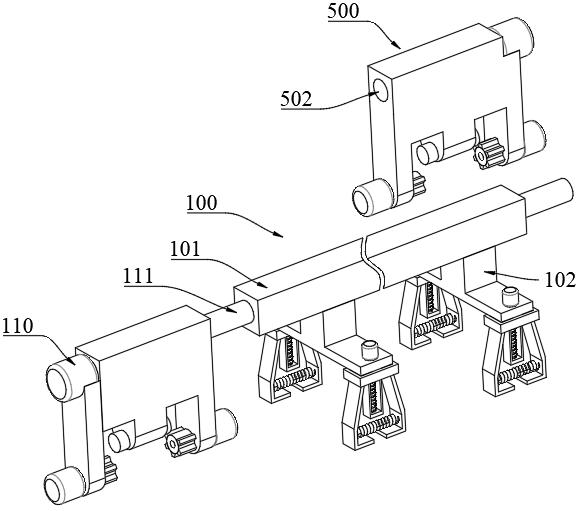

[0039] Insert the first transmission shaft 111 of the clamping mechanism 100 into the first installation hole 502 of the stroke mechanism 500, and then be stuck in the connecting rod 101, so that the sixth motor 110 is fixed on the stroke block 501, and then the stroke mechanism 500 is removed from the track 300 into the linear track, make the gear 506 cooperate with the gear groove 301, and the roller 509 cooperate with the chute 302, so that the clamping mechanism 100 can move on the track under the cooperation of the stroke mechanism 500, and then the linear track of the track 300 The part is assembled with the arc track part;

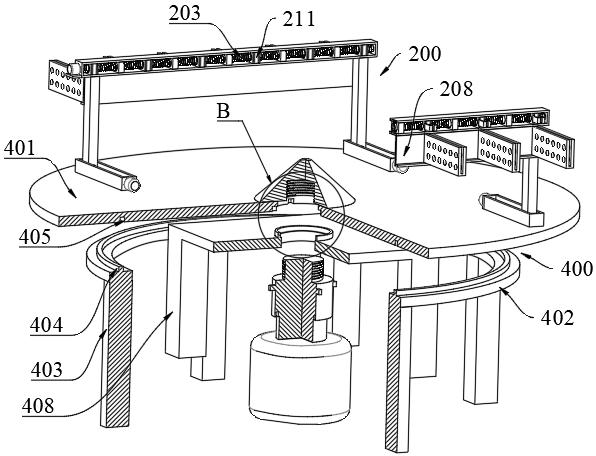

[0040] The rotating disk 401 is placed on the supporting round table 402, the first ring groove 405 on the lower end surface of the rotating disk 401 is matched with the first ring table 404 on the upper end surface of the supporting round table 402, and then the second transmission shaft...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap