Supporting device capable of adjusting elevation of bent cap end chamfering formwork and construction technology

A supporting device and adjustable technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of limited use scenarios and inability to adjust the elevation of the vertical formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

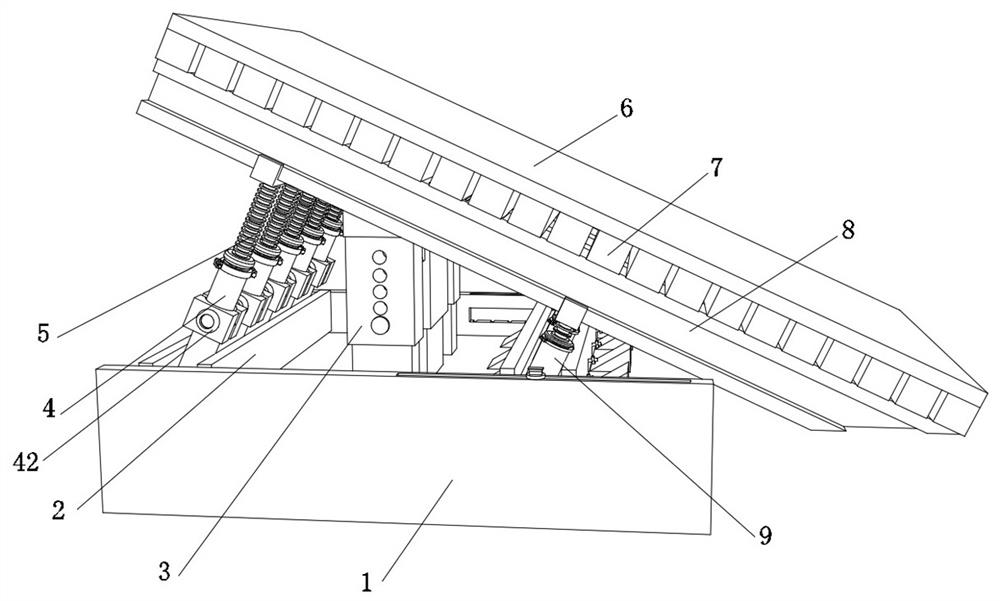

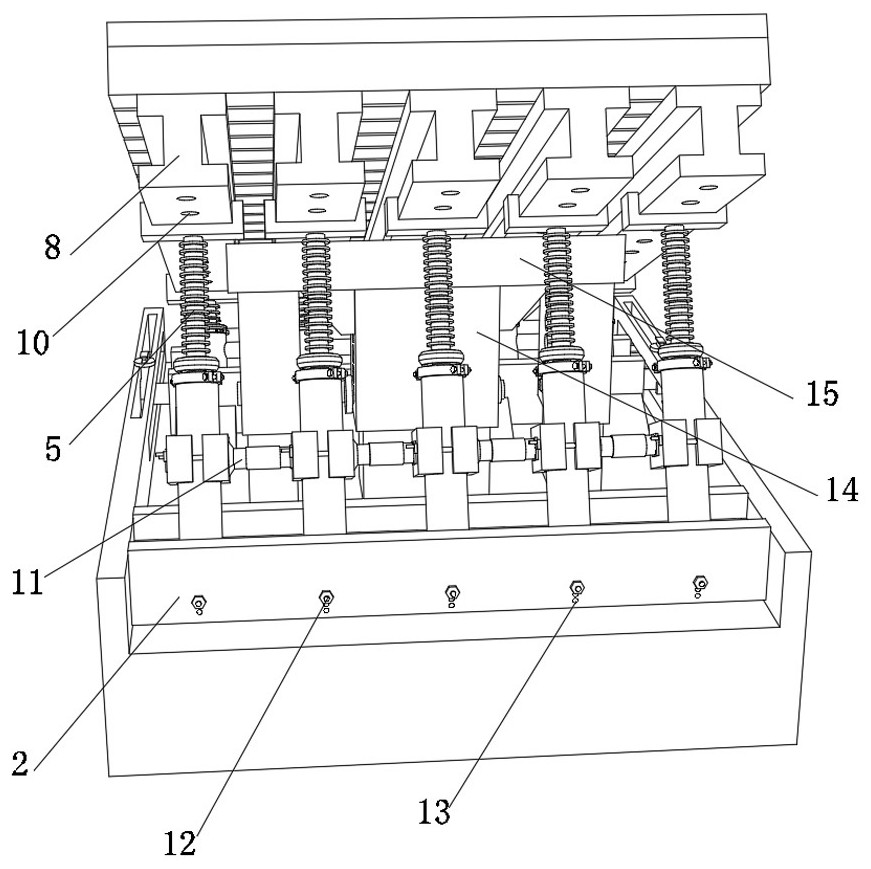

[0047] A support device that can adjust the height of the chamfering formwork at the end of the cover beam, such as figure 1 , figure 2 , Figure 4 and Figure 7 As shown, it includes two first I-beams 2, the top outer walls of the two first I-beams 2 are provided with a plurality of circular grooves, and the circumferential inner walls of the multiple circular grooves are all fixed with elastic shrink covers 23 by bolts. The inner wall of the elastic shrink cover 23 is welded with a rubber block 22, and the outer wall of the elastic shrink cover 23 is fixed with two elastic connectors 30 by bolts. One end of the two elastic connectors 30 is respectively fixed to the same first I-beam 2 by bolts the inner wall on the opposite side. Two sets of inclined holes 13 are provided on one side of the first I-beam 2, and the number of each set of inclined holes 13 is not less than two. Preferably, in this embodiment, the number of inclined holes 13 in each set is The number is thr...

Embodiment 2

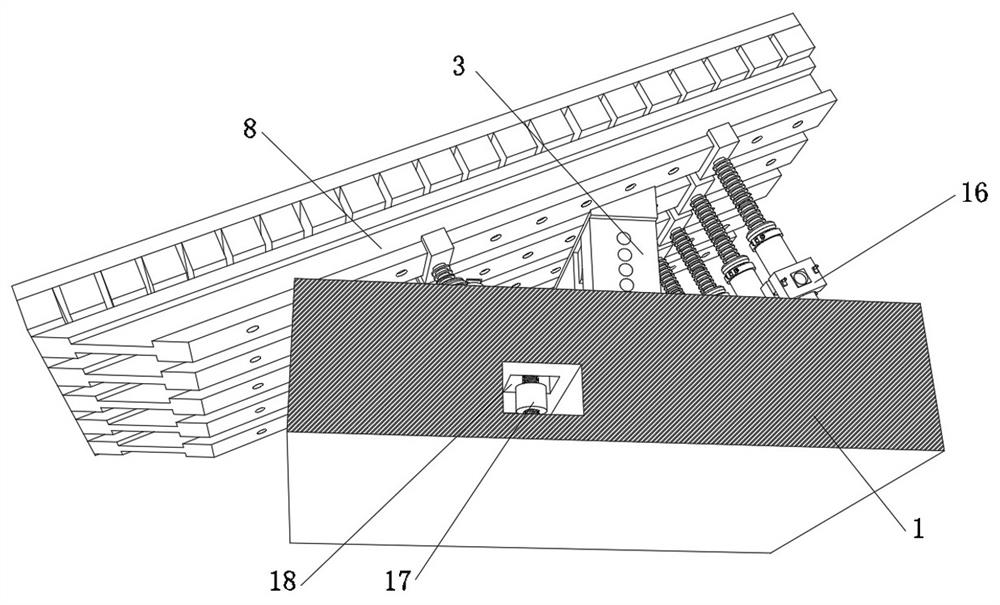

[0052] A support device that can adjust the height of the chamfered formwork at the end of the cover beam. In order to effectively avoid the deformation of the load-bearing structure during use, such as Figure 1-6 As shown, the bottom outer wall of one of the first I-beams 2 is fixed with a base 1 by bolts, and the bottom outer walls of a plurality of second I-beams 8 are fixed with the same backing plate 15 by bolts, and the backing plate 15 The outer wall of the bottom is fixed with at least two adjustment columns 3 by bolts, and the outer wall of the backing plate 15 close to the bottom of the two adjustment columns 3 is fixed with a second adjustment column 14 by bolts, and the outer walls on both sides of the second adjustment column 14 are fixed with reinforcement by bolts. The corner plate, the extension ends of the two adjustment columns 3 and the extension end of the second adjustment column 14 are all plugged into the top outer wall of the base 1; the bottom inner wa...

Embodiment 3

[0056] A construction technique for the support device of the adjustable cover beam end chamfering formwork elevation described in Embodiment 1 and Embodiment 2, such as Figure 1-11 shown, including the following steps:

[0057] S1: install the first steel pipe 4 and the second steel pipe 9 with the two first I-beams 2 respectively, and adjust the inclination angle through the positioning pin 12 and the shackle 31;

[0058] S2: install the threaded column 5 in the first steel pipe 4 and the second steel pipe 9, and install connecting structures and connecting columns between the plurality of first steel pipes 4 and the plurality of second steel pipes 9;

[0059] S3: Adjust the position of one of the first I-beams 2 in the two long grooves 19, and use the limit plate 20 to limit the position;

[0060] S4: Fix the load-bearing structure on the threaded column 5, and rotate the threaded column 5 to operate and adjust the height of the chamfering formwork;

[0061] S5: adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com