Hidden frame type curtain wall lamp installation assembly

A lamp installation and frame-type technology, which is applied to the components of lighting devices, walls, building components, etc., can solve safety problems, destroy the airtightness and watertightness of glass curtain walls, and the glass curtain wall and lighting equipment cannot be well integrated And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

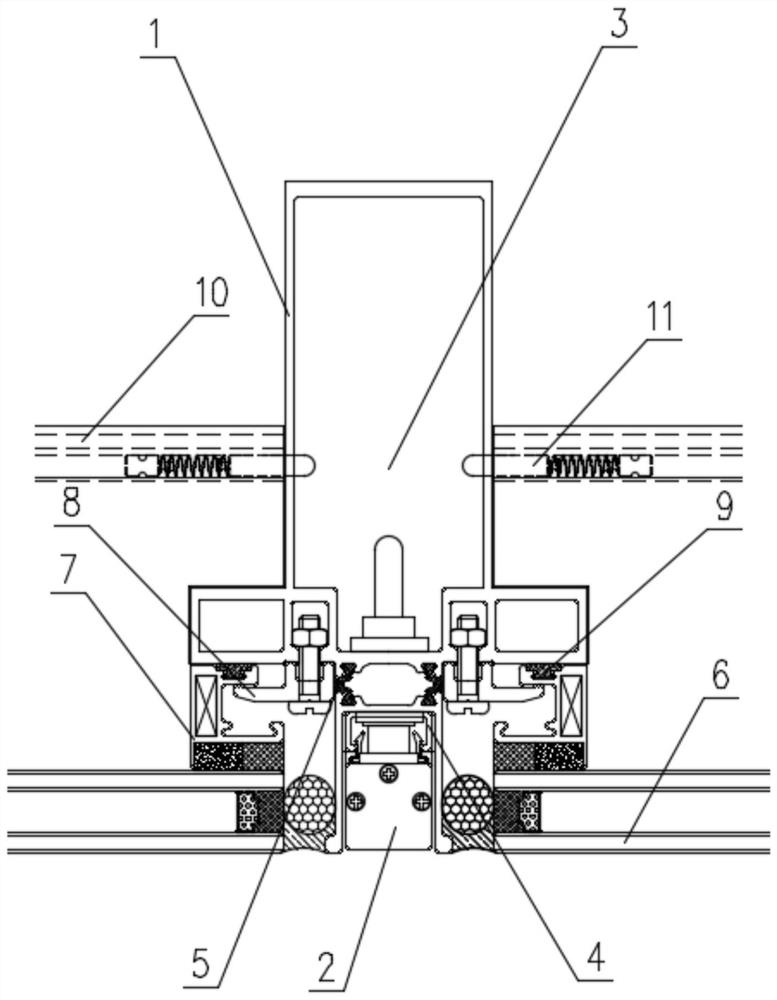

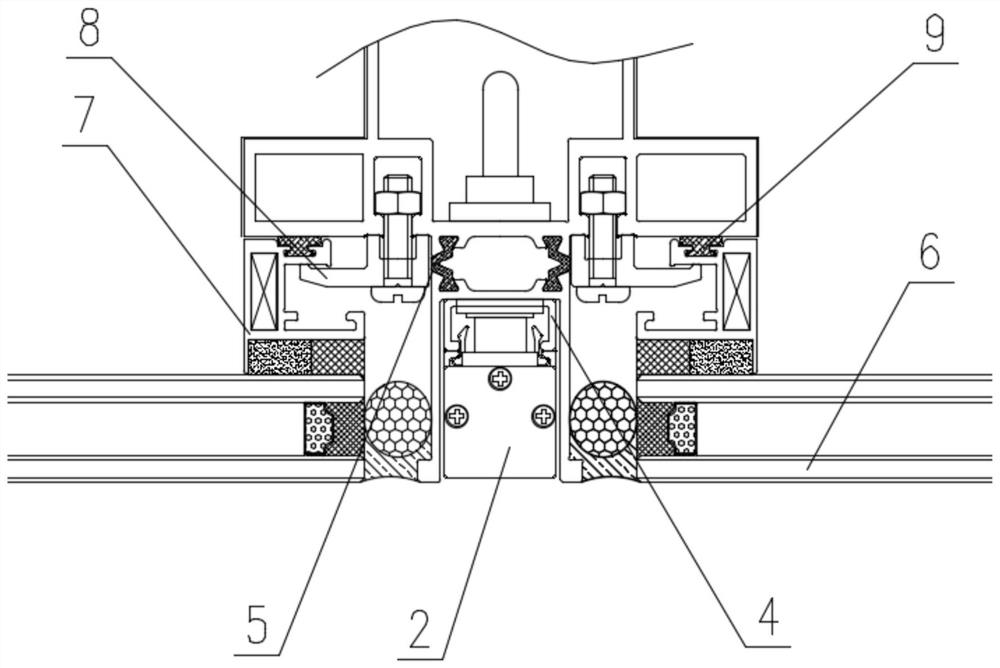

[0028] Such as figure 1 with figure 2 Shown:

[0029] A hidden frame frame type curtain wall lamp installation assembly, including a column 1 and a lamp body 2, the column 1 is made of aluminum alloy material, the cross section of the column 1 is a T-shaped structure, and the interior of the column 1 is provided with a cavity for laying cables 3. The lamp cable is laid concealed by means of the cavity 3 in the stand 1.

[0030] The width of the front end of the column 1 is slightly wider than that of the traditional hidden frame glass curtain wall, but because the aluminum alloy column adopts a T-shaped structure, the lighting effect of the glass curtain wall does not change significantly, which can ensure the normal use effect of the glass curtain wall. After the front end of the column is widened, a 27mm lamp installation space is reserved between the two glass curtain walls. This space can completely conceal the LED strip video lamps commonly used in the market today. T...

Embodiment 2

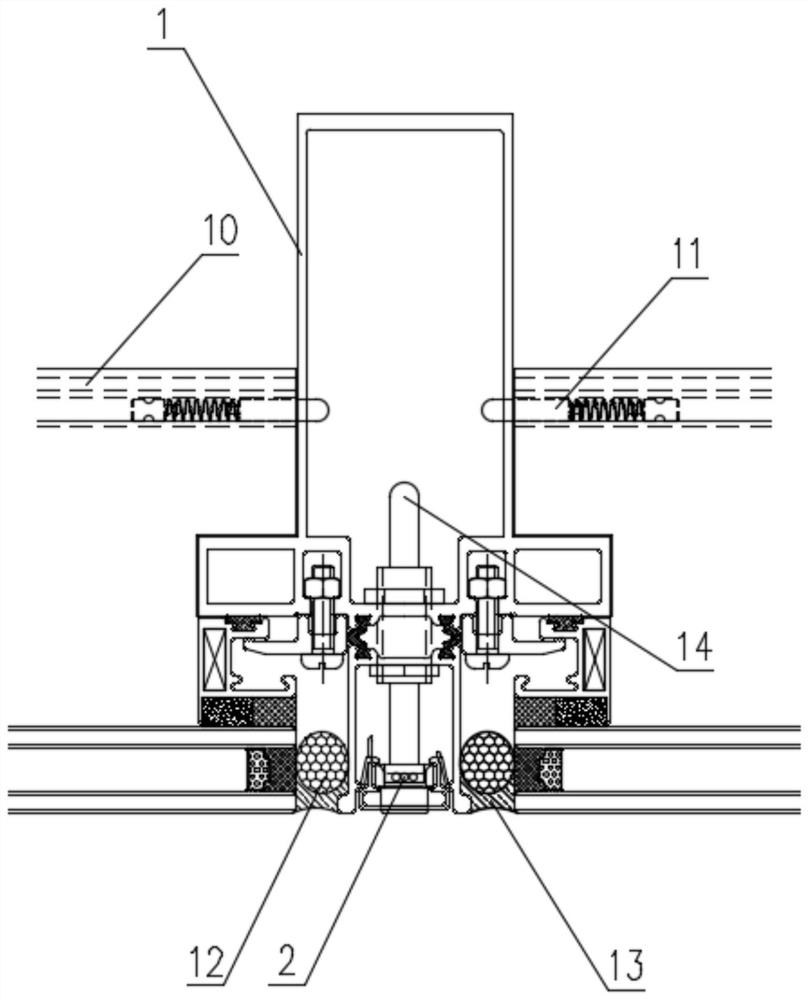

[0037] Such as image 3 with Figure 4 As shown, the structure of this embodiment is basically the same as that of Embodiment 1. The difference is that in this embodiment, the lamp body installed in the 27mm lamp installation space reserved between the two glass curtain walls is a commonly used lamp in the market. The low-power LED point light source lamp realizes the concealed installation of the lamp, and the point light source lamp and the lamp installation attachment frame 4 are also snap-connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com