Focusing structure

A technology of slotting and connecting blocks, which is applied in the field of focusing structure, can solve the problems of reducing the focusing speed of the lens and low rotation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

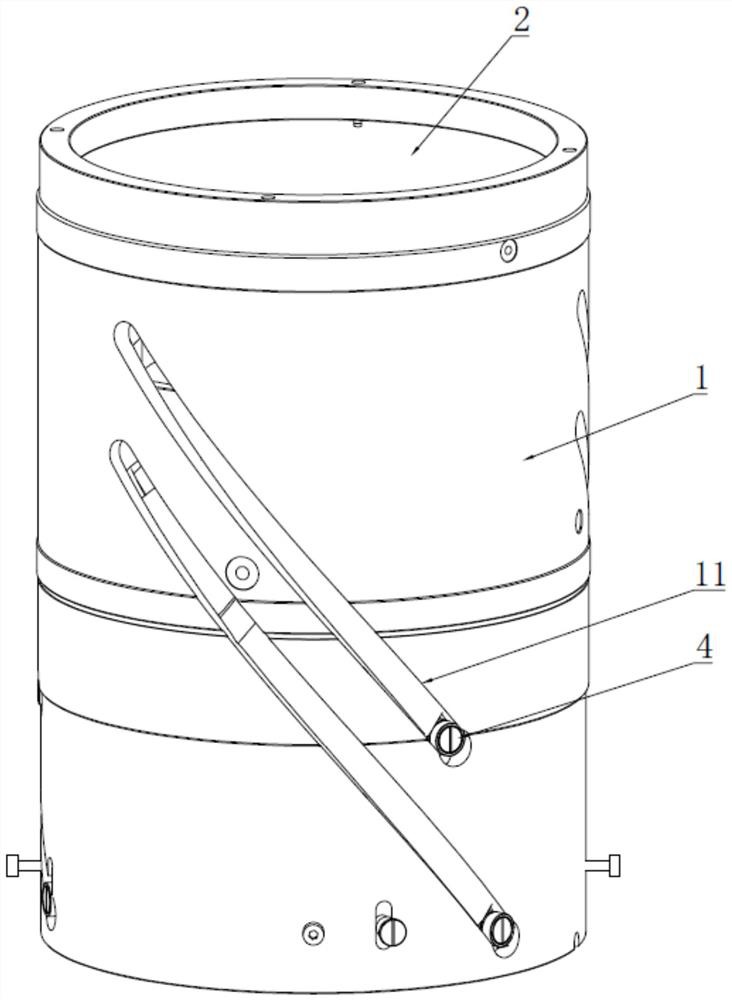

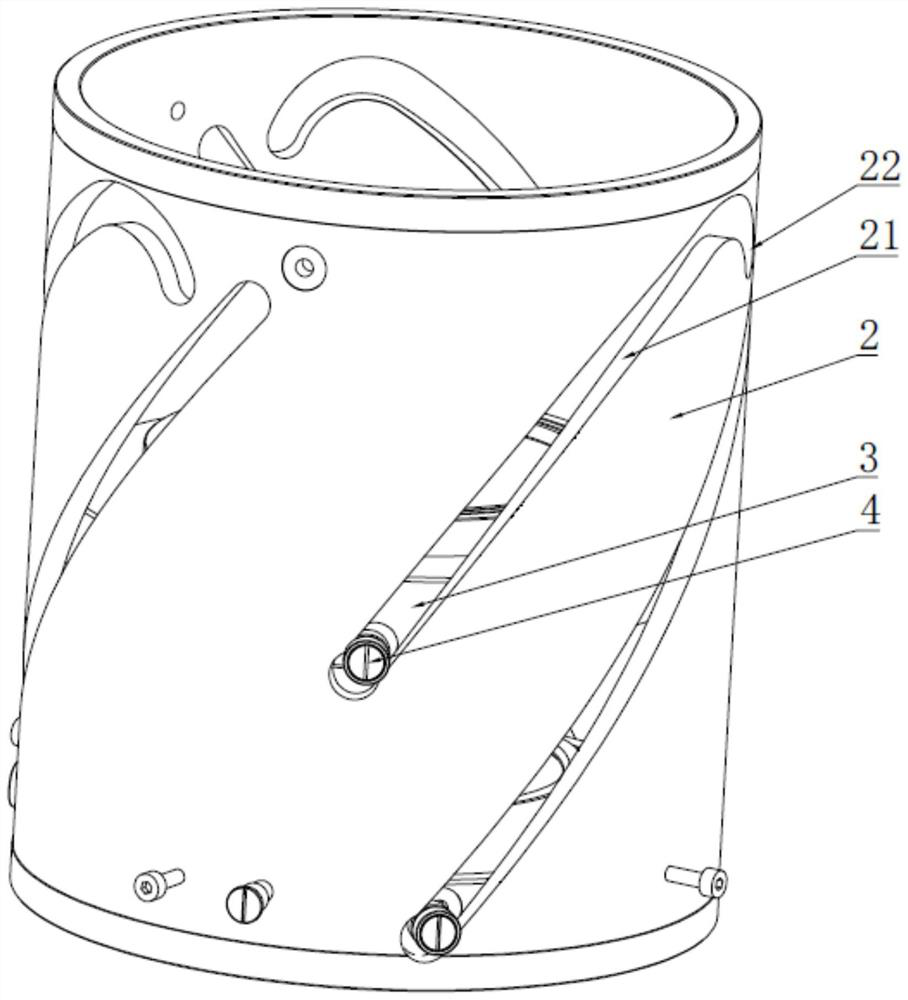

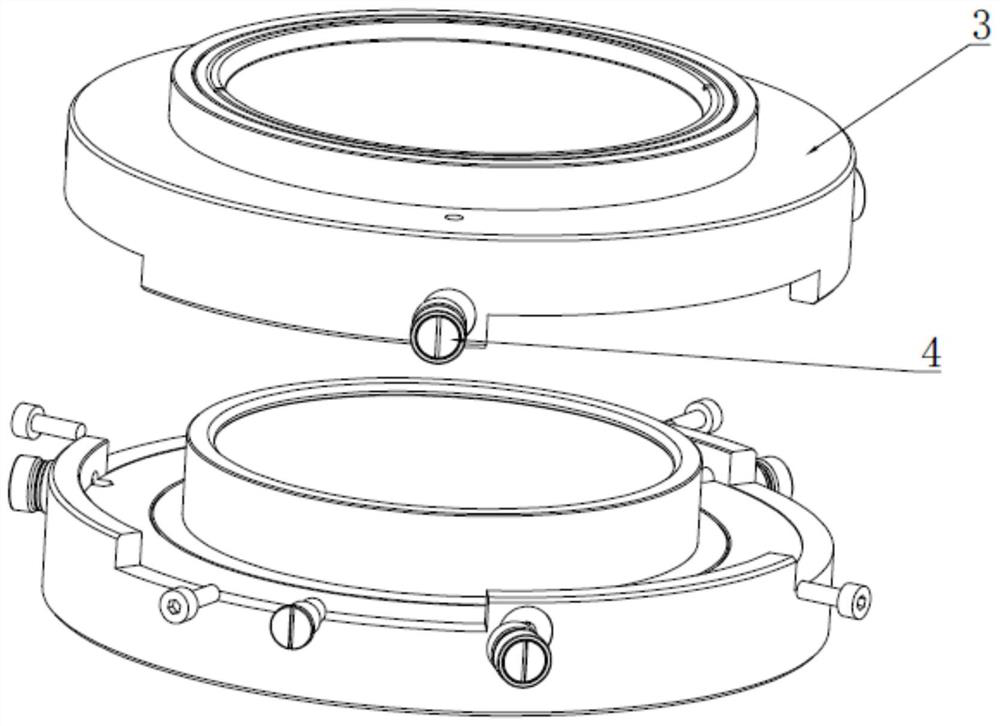

[0045] Such as Figure 1 to Figure 3 As shown, a focusing structure includes a coaxial fixed cylinder 1, a connecting cylinder 2 and a moving group 3. In this embodiment, the fixed cylinder 1 is arranged on the outermost side, and the connecting cylinder 2 is arranged on the inner side of the fixed cylinder 1. The moving group 3 is arranged in the connecting cylinder 2; the connecting cylinder 2 is provided with a first sub-groove 21, and the fixed cylinder 1 is provided with a second sub-groove 11, and the first sub-groove 21 and the second sub-groove are connected to each other. The rotation directions of the grooves 11 are opposite. In this embodiment, the first sub-grooves 21 are opened in a right-handed direction, and the second sub-grooves 11 are opened in a left-handed direction.

[0046] The moving group 3 is provided with a first connecting block 64, and the first connecting block 64 is slidably connected to the first sub-groove 21.

[0047] Optionally, the fixed cyl...

Embodiment 2

[0053] On the basis of Example 1, such as Figures 2 to 5 As shown, in this embodiment, when the first connecting block 64 slides in the first sub-groove 21 along the rotation direction of the first sub-groove 21, the connecting cylinder 2 moves along the second sub-groove. The opening direction of 11 is rotated.

[0054] In this embodiment, the sliding of the first connecting block 64 can drive the connecting cylinder 2 to rotate along the opening direction of the second sub-groove 11, that is, the connecting cylinder 2 can move along the axis of the connecting cylinder 2, and the moving group When the moving stroke of 3 is fixed, the rotation angle of the connecting cylinder 2 is further reduced, the time required for the connecting cylinder 2 to rotate is reduced, the rotating efficiency of the connecting cylinder 2 is increased, and the focusing speed of the lens is increased.

[0055] The fixing cylinder 1 is further provided with a limiting groove 12, the limiting groov...

Embodiment 3

[0067] On the basis of embodiment 1 or 2, such as Figure 1 to Figure 5 As shown, the second sub-groove 11 is a helix; and / or the first sub-groove 21 is a helix.

[0068] By setting the first sub-groove 21 and / or the second sub-groove 11 as a helical line, when the connecting cylinder 2 rotates at a constant speed, it drives the moving group to rotate at a constant speed, which increases the reliability of the focusing structure during movement.

[0069] One or more first sub-grooves 21 are provided, and the spacing between adjacent first sub-grooves 21 along the axis direction of the connecting cylinder 2 is the same as the lens spacing of the lenses in the corresponding state.

[0070] Through the setting of a plurality of first sub-slots 21, the synchronous movement of a plurality of mobile groups 3 has been realized, and the moving efficiency of the mobile groups 3 has been increased.

[0071] The end portion of the first sub-slot 21 is also provided with an extension slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com