Beam bending deformation simulation system based on complex working conditions of projects and used in material mechanics teaching

A technology of material mechanics and complex working conditions, applied in the field of teaching aids, can solve problems such as unfavorable, unintuitive learning methods, and learning effects that need to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

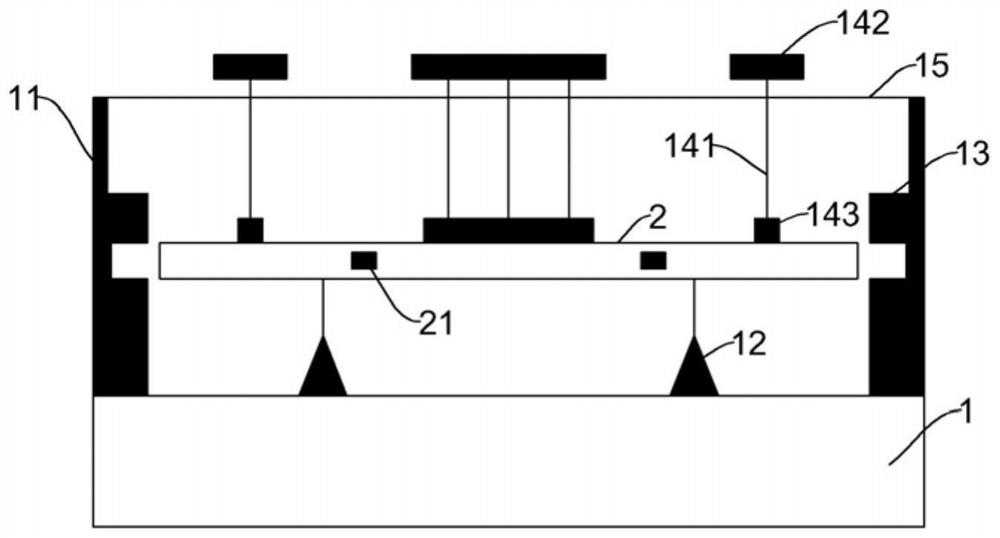

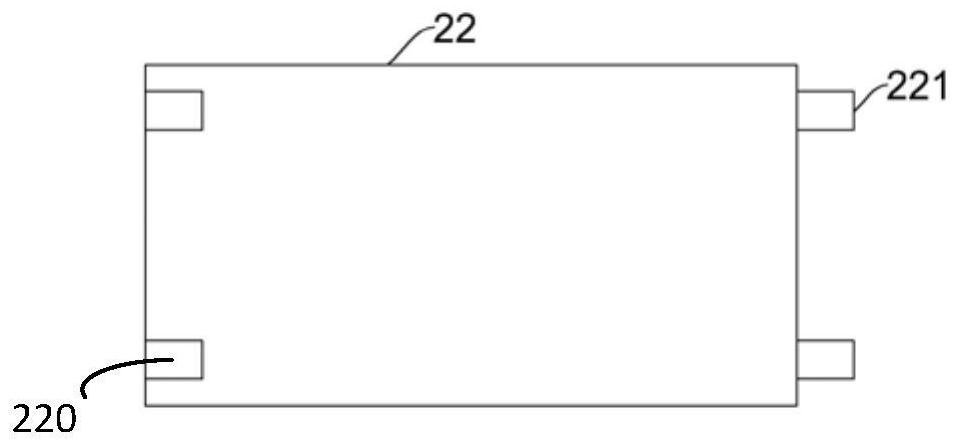

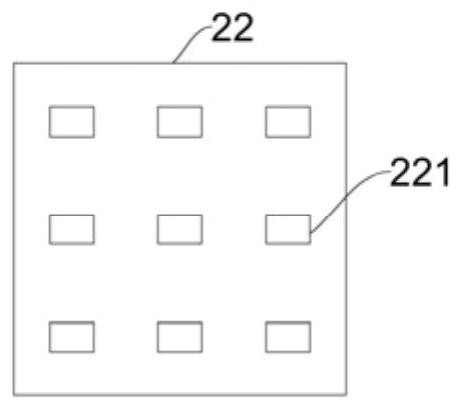

[0025] see figure 1 According to the beam bending deformation simulation system based on engineering complex working conditions in the teaching of material mechanics provided by the present invention, it includes an experimental platform, rods, force application components, and restraint components. The experimental platform includes a base 1, side columns 11 and a top The horizontal plate 15, the base 1, the side column 11 and the top horizontal plate 15 form a frame structure, and the rod 2 is located inside the space formed by the base 1, the side column 11 and the top horizontal plate 15. The force application component includes a force component and a force couple component, the force component passes through the top horizontal plate 15 and contacts the rod 2, and the force couple component is located between the rod 2 and the surface of the base 1, so The constraint assembly includes a hinge support 12 and a fixed end support 13, the hinge support 12 is in contact with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com