Super-bright full-color-gamut Mini LED packaging structure

A technology of packaging structure and color gamut, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of prolonged product production cycle, low speed, and inaccurate and consistent dispensing volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

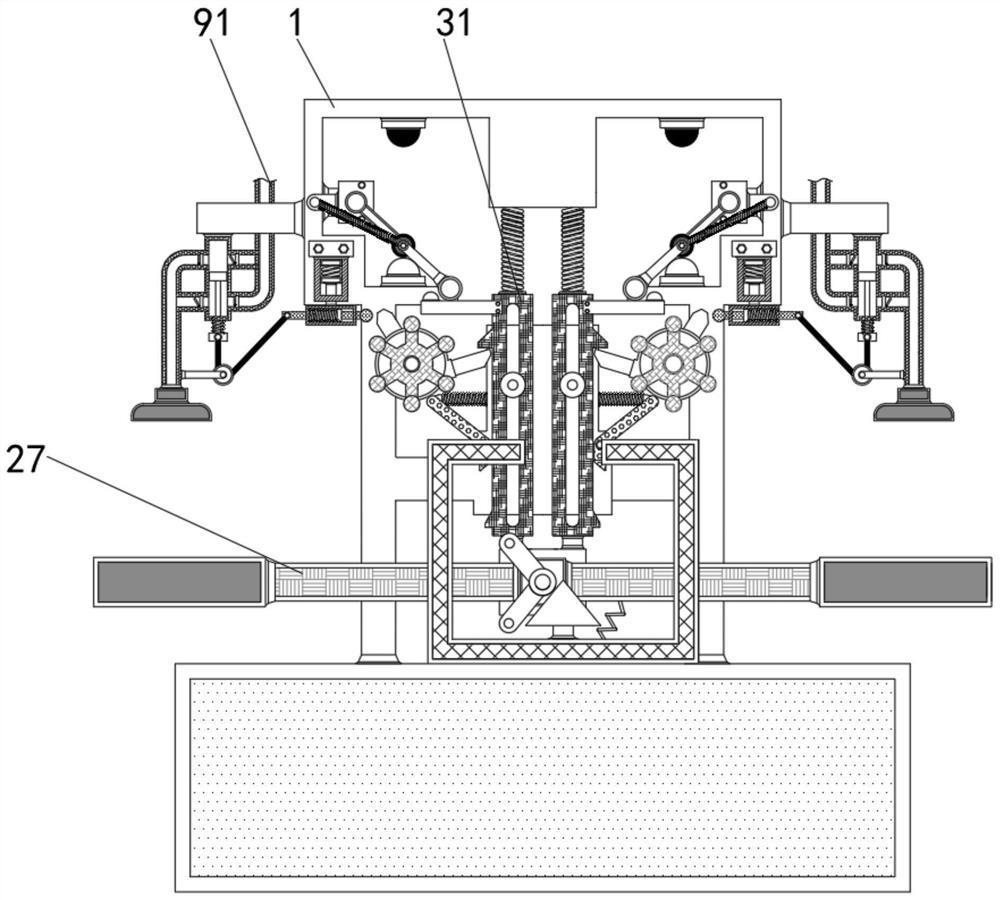

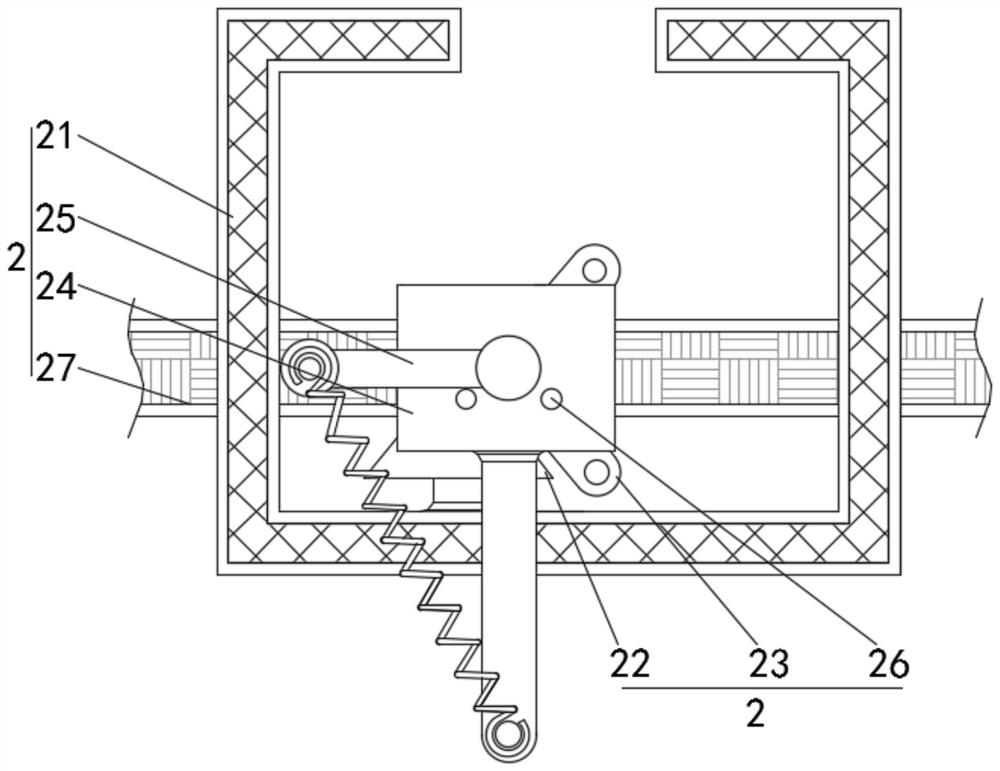

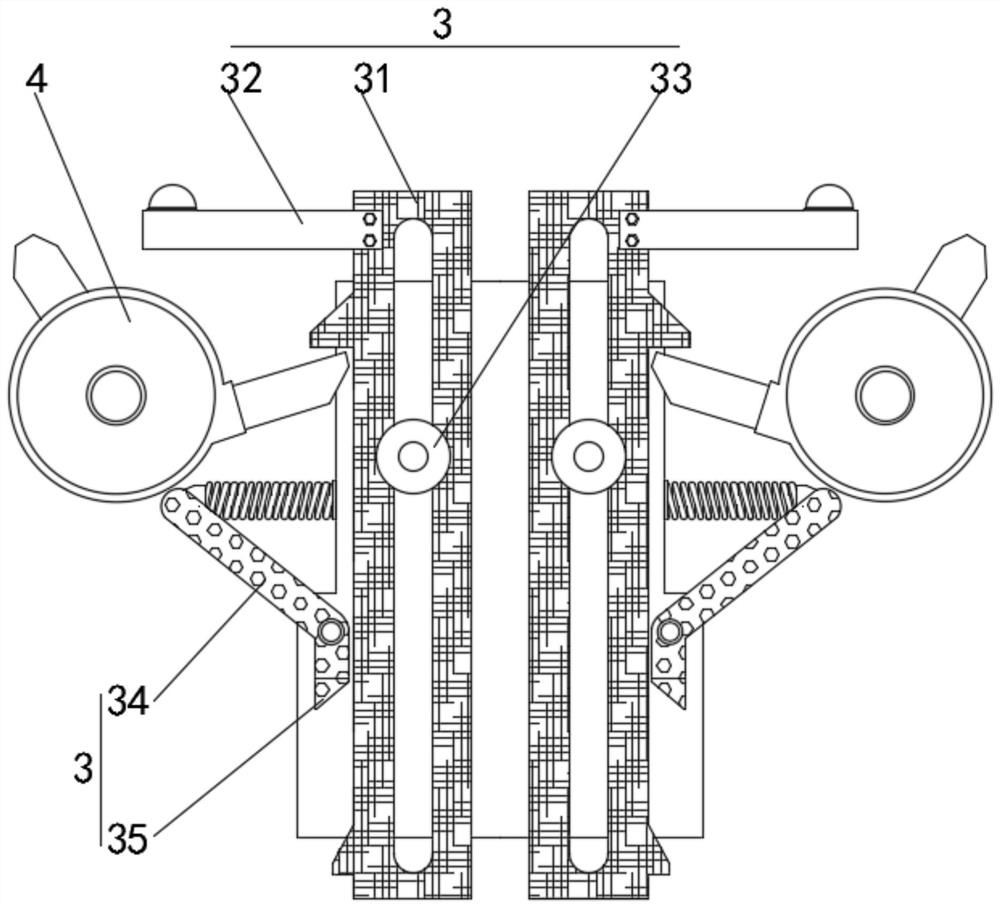

[0026] see Figure 1-3 , an ultra-bright full-color gamut Mini LED packaging structure, including a frame body 1, the upper side of the frame body 1 is slidably connected with a flipping component 2, and the flipping component 2 includes a motion frame 21, and the upper side of the motion frame 21 is fixedly connected with a triangular block 22. The upper side of the triangular block 22 is provided with a rotating block 23, the upper side of the rotating block 23 is provided with a drive assembly 3, the left side of the drive assembly 3 is slidingly connected with a control assembly 6, and the lower side of the control assembly 6 is provided with a linkage assembly 8 , the lower left side of the linkage assembly 8 is fixedly connected with the spraying assembly 9 .

[0027] Further, the outer side of the rotating block 23 is rotatably connected with a movable block 24, the front side of the rotating block 23 is fixedly connected with a rotating rod 25, the rear side of the rot...

Embodiment 2

[0030] see Figure 1-6 , an ultra-bright full-color gamut Mini LED packaging structure, including a frame body 1, the upper side of the frame body 1 is slidably connected with a flipping component 2, and the flipping component 2 includes a motion frame 21, and the upper side of the motion frame 21 is fixedly connected with a triangular block 22. The upper side of the triangular block 22 is provided with a rotating block 23, the upper side of the rotating block 23 is provided with a drive assembly 3, the left side of the drive assembly 3 is slidingly connected with a control assembly 6, and the lower side of the control assembly 6 is provided with a linkage assembly 8 , the lower left side of the linkage assembly 8 is fixedly connected with the spraying assembly 9 .

[0031] Further, the outer side of the rotating block 23 is rotatably connected with a movable block 24, the front side of the rotating block 23 is fixedly connected with a rotating rod 25, the rear side of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com