Part deformation correcting device and using method thereof

A calibration device and parts technology, which is applied in the field of parts deformation correction, can solve the problems of insufficient efficiency and convenience of calibration and verification, and the size of parts cannot meet the design requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

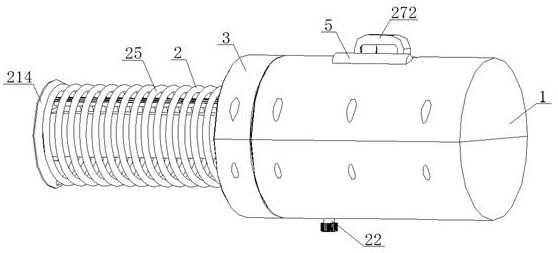

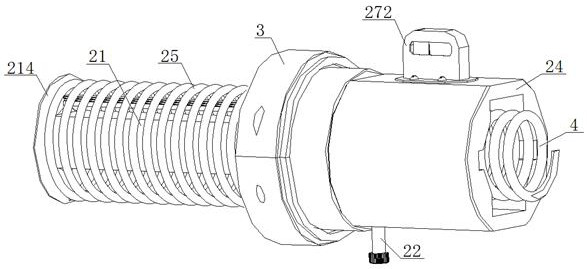

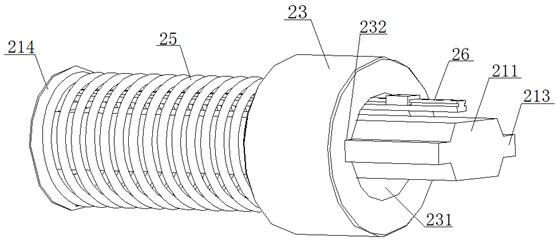

[0056] see Figure 1 to Figure 4 , a component deformation correction device, the correction device includes a housing 1 open at one end, a calibration verification assembly 2, an adjustment nut 3, a tension spring 4, a level 5, and the calibration verification assembly 2 is arranged on the housing 1 Inside, it includes a push rod 21, a follower set screw 22, an adjustment block 23, a follower sleeve 24, a spring 25, a guide rail 26, an indicator needle-dial assembly 27, and a sliding block 28. The indicator needle-dial assembly 27 includes The indicator needle 271, the dial 272 matched with the indicator needle 271, the adjustment nut 3, the ejector rod 21, the adjustment block 23, and the follower sleeve 24 are arranged coaxially with the housing 1, and the adjustment nut 3 is sleeved on the adjustment block 23 outside, the inner wall of the adjusting nut 3 is threadedly connected with the outer wall of the adjusting block 23, and the end faces of the adjusting nut 3 and the...

Embodiment 2

[0063] The difference with embodiment 1 is:

[0064] see Figure 5 , the correction device also includes a protective cover 6 with an open end, the inner wall of the open end of the protective cover 6 is threadedly connected with the outer wall of the adjustment nut 3, and one end of the guide rail 26, the B end 212, the spring 25, and the pressure plate 213 are all located at the protective cover. In the inside of the cover 6, the protective cover 6 can be removed during work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com