Paper separating mechanism for printer

A paper feeding mechanism technology for printers, applied in the direction of pile separation, object separation, object supply, etc., can solve the problems of low probability of pagination and easily damaged paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

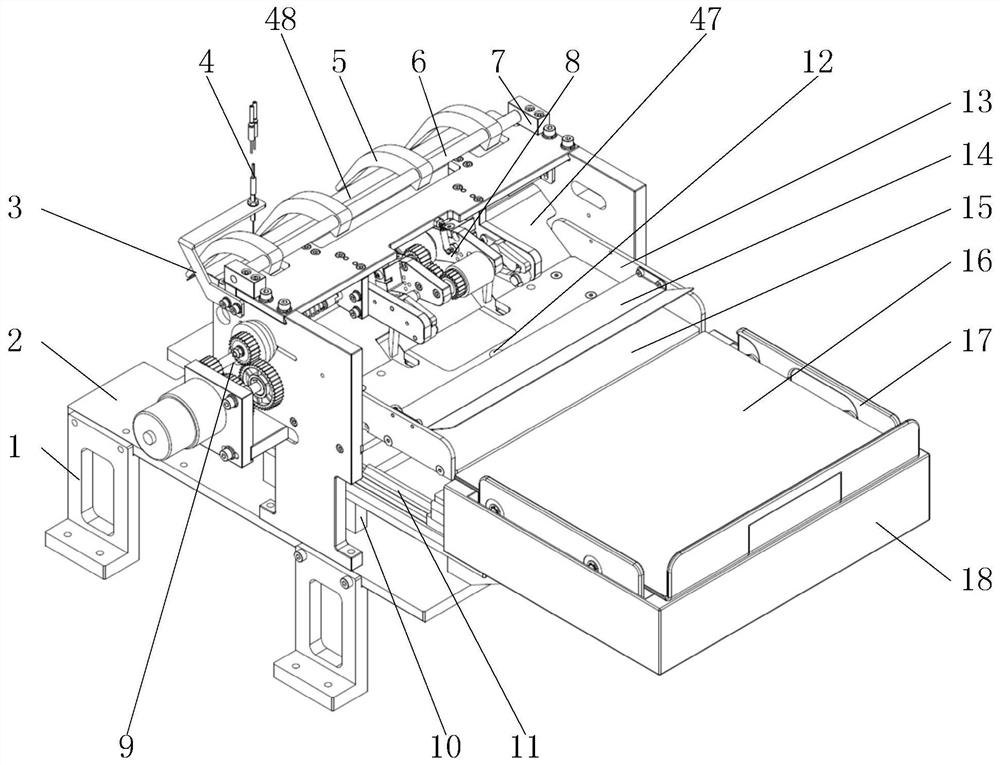

[0050] Such as Figure 1 ~ Figure 3 As shown, a paper separating mechanism for a printer includes a fixed substrate 2, a paper feeding mechanism 8, a paper separating mechanism 9 and a carton mechanism. Paper mechanism 8, paper separation mechanism 9 and paper box mechanism, paper box mechanism, paper feeding mechanism 8 and paper separation mechanism 9 are installed on the fixed substrate 2 in sequence along the negative direction of X axis, and the paper box mechanism is connected with the feeding board 15 through the paper box mechanism. The paper mechanism 8 is connected, and the paper feeding mechanism 8 and the paper separating mechanism 9 are separated by the front paper guide plate 47 and the rear paper guide plate 48 in sequence along the negative direction of the X axis. 48 are sequentially connected to each other along the negative direction of the X axis;

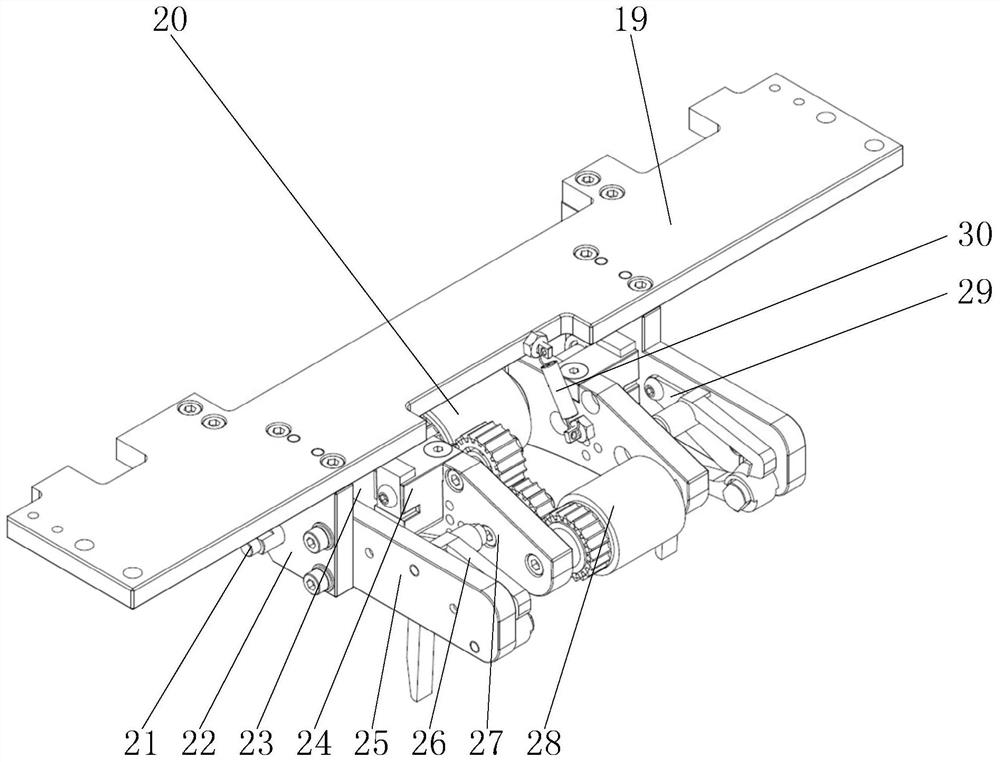

[0051] The paper feeding mechanism 8 includes a top plate 19, a paper feed wheel 20 and a pickup wheel 28. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com