Wall surface net hanging layer and net hanging wall

A technology of mesh layer and mesh cover, which is applied in the field of wall hanging mesh layer and hanging mesh wall, which can solve the problems of low grout hanging force on mortar wall, steel wire mesh is not easy to cling to the wall, and hanging wall is gray and hollow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

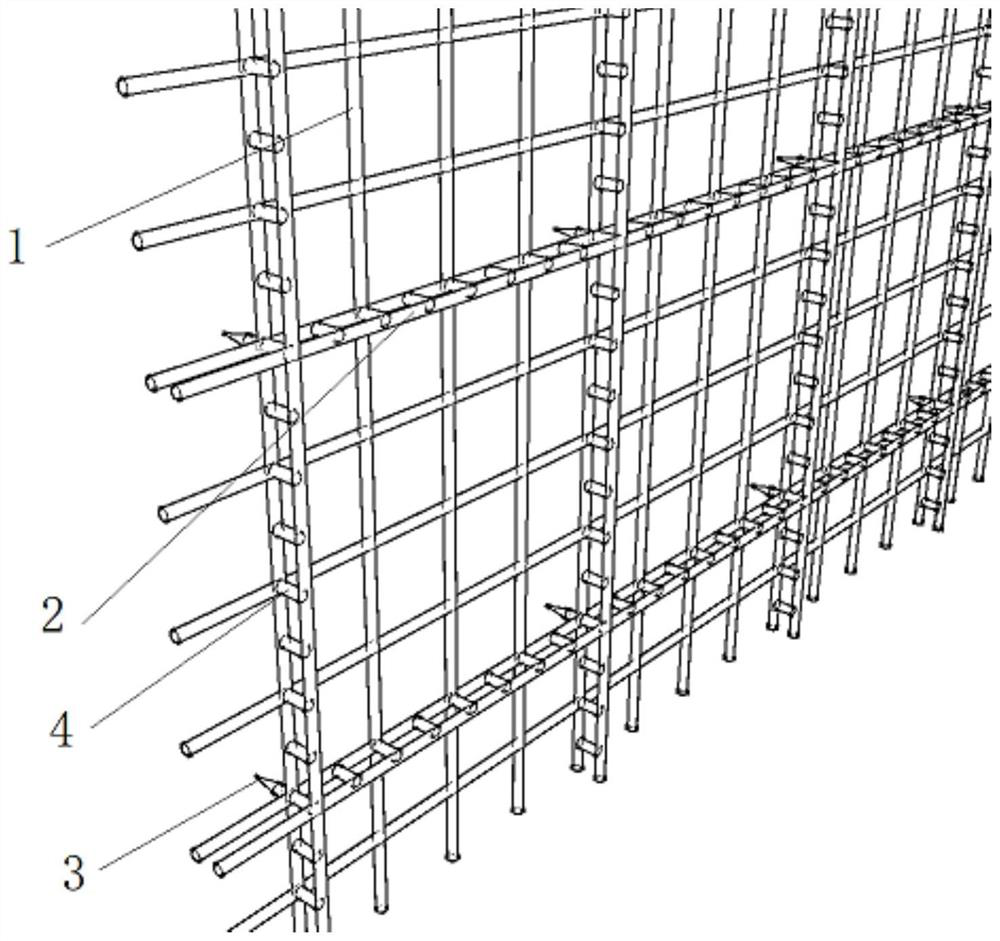

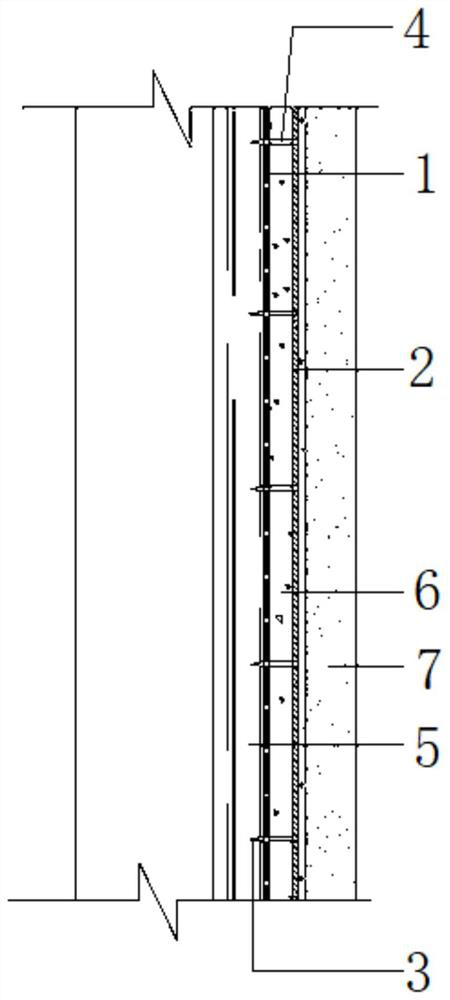

[0025] Such as figure 1 As shown, a kind of wall hanging mesh layer disclosed by this patent is provided with a square mesh cover 2 on the front of the single-layer mesh 1 to increase the strength of the mortar hanging on the wall when the wall is plastered. The back side is provided with fixing nail 3, strengthens the wall surface hanging net layer to stick to the wall surface fixity.

[0026] For the hanging mesh layer on the wall, the traditional large-aperture 100mm single-layer mesh 1 is used as the original base layer. The single-layer mesh 1 can choose steel wire mesh, which has certain corrosion resistance and the function of a supporting system. The aperture size of 100mm is convenient. The plaster layer is firmly bonded to the base layer to improve the adhesion. The front of the single-layer mesh 1 is covered with a grid cover 2, the distance between the grid cover 2 and the single-layer mesh 1 is not more than 200mm, the grid cover 2 can be made of steel wire, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com