Automatic cable stripping device

A stripping device, fully automatic technology, applied in the direction of cable installation, cable installation, dismantling/armored cable equipment, etc., can solve the problem of laborious stripping of cable insulation, and achieve high stripping efficiency and automation High and reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

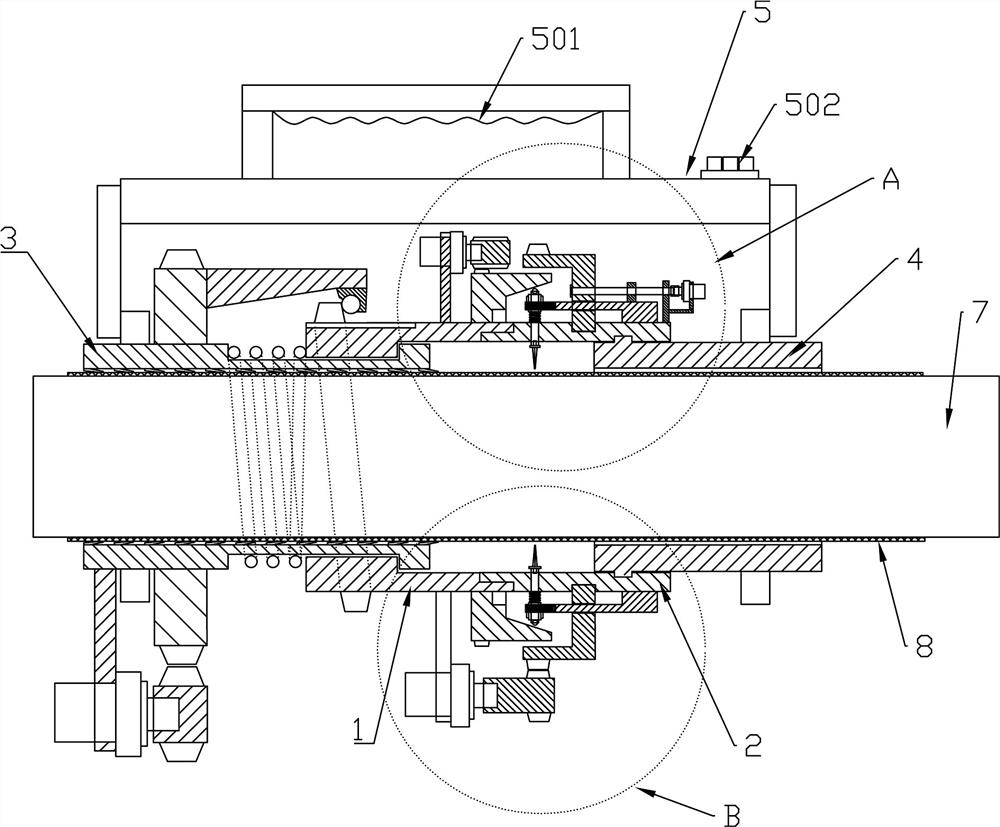

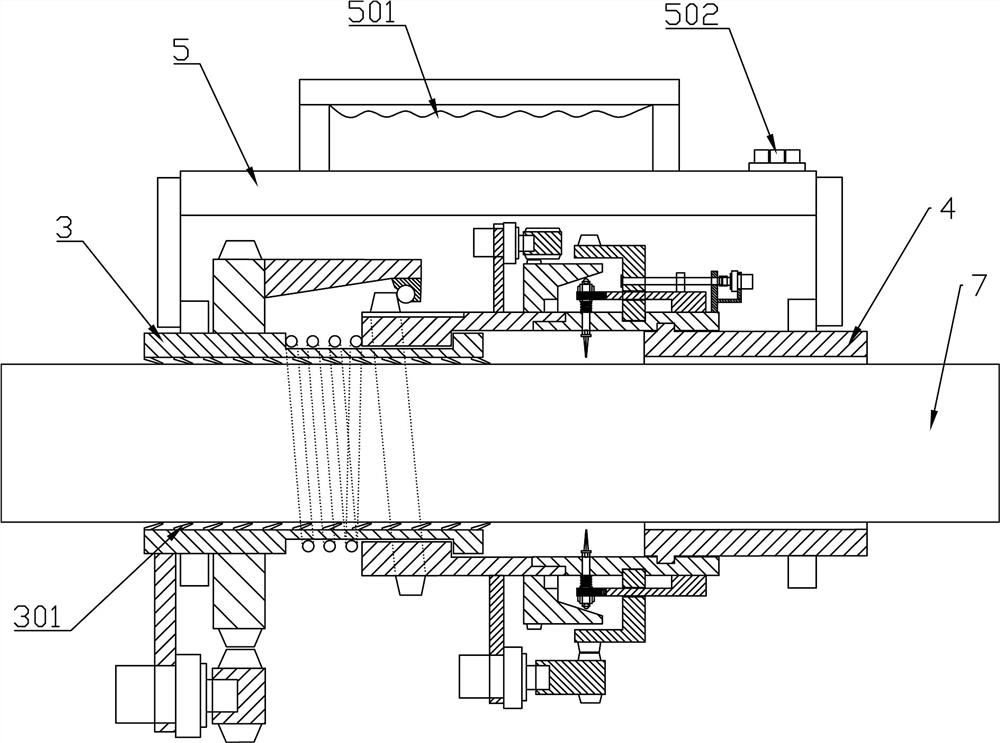

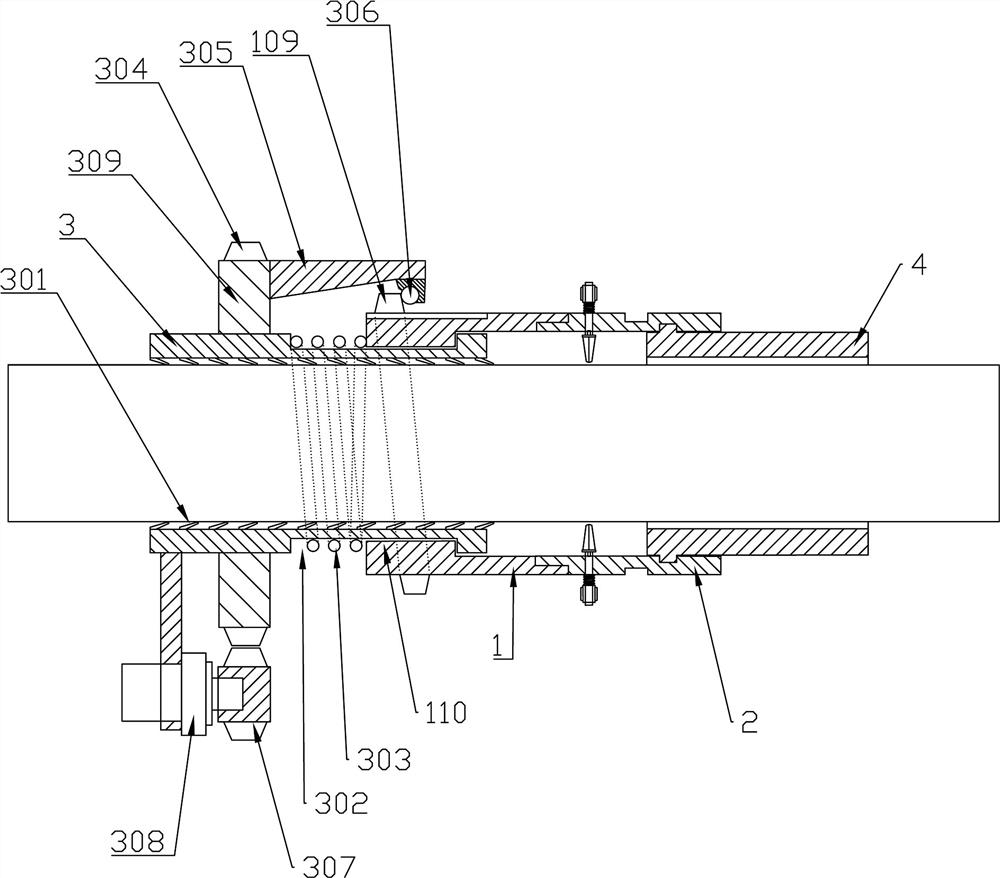

[0030] like Figure 1-11 Among them, an automatic cable stripping device includes a front end tube 3, a first movable tube 1 that can reciprocate and slide is sleeved on one side of the front end tube 3, and a rotatable first movable tube 1 is sleeved at one end of the first movable tube 1 away from the front end tube 3. Two movable tubes 2, the second movable tube 2 is provided with a cutter assembly 6, there are multiple cutter assemblies 6, the end of the second movable tube 2 away from the first movable tube 1 is sleeved with a rear end tube 4, and the inner wall of the front end tube 3 A first one-way spine 301 is provided, and a second one-way spine 401 is provided on the inner wall of the rear end tube 4. The first one-way spine 301 and the second one-way spine 401 are used to pass the cable 7 in one direction. The first one-way spine The spine 301 and the second one-way spine 401 have a certain elasticity and face the same direction. When the front end tube 3 and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com