A motor prefabricated winding embedding equipment

A winding and equipment technology, applied in the field of motor prefabricated winding embedding equipment, can solve the problems of scattered ends of prefabricated windings, scattered prefabricated windings, uneven ends of prefabricated windings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

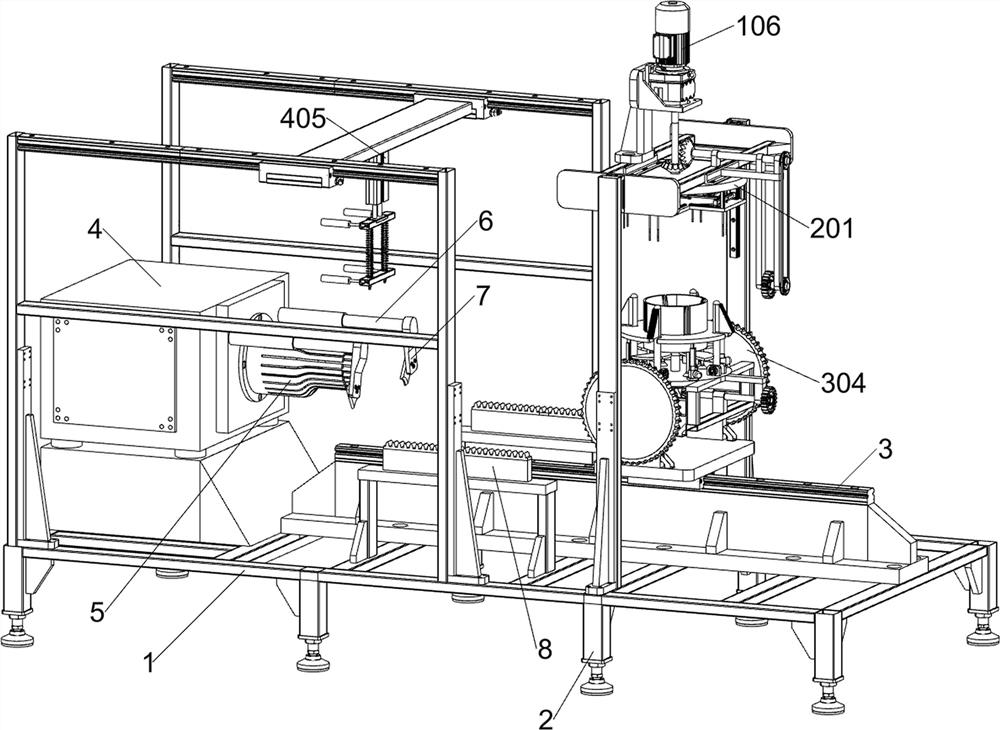

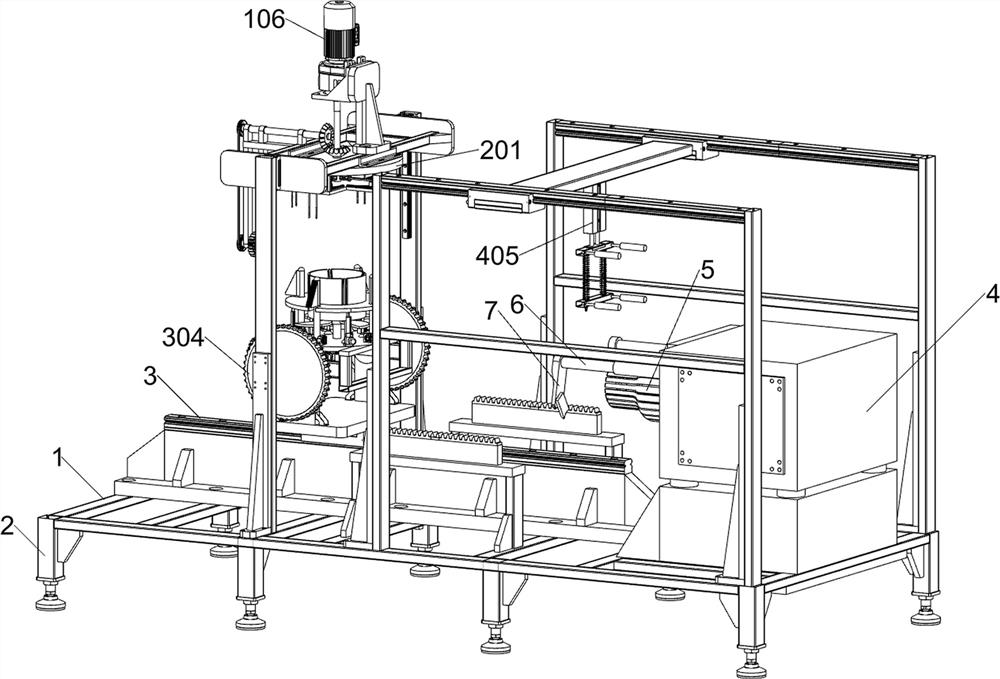

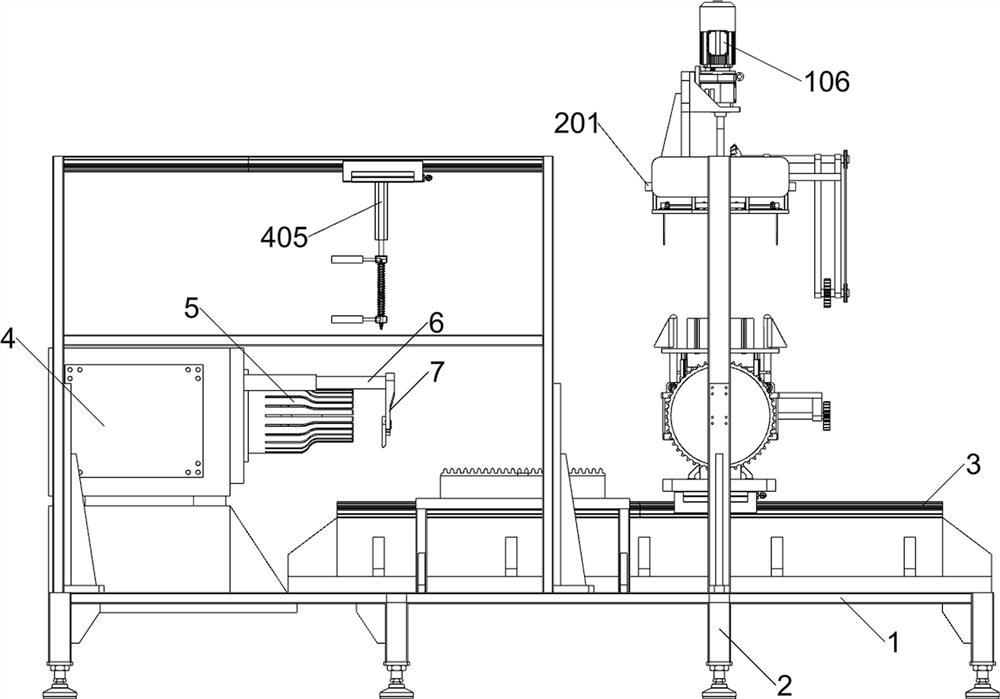

[0040] A motor prefabricated winding embedding device, according to Figure 1-3 As shown, it includes a chassis 1, a support 2, a first electric slide rail 3, a press 4, a support sleeve 5, a rotating telescopic rod 6, a baffle 7, a rack 8, a first support 101, a second Electric slide rail 102, fourth electric slider 103, sliding frame 104, drive unit, carding unit, material sorting unit and assembly unit; bottom frame 1 is fixedly connected with support 2; Electric slide rail 3; a press 4 is fixedly connected to the upper left part of the bottom frame 1; a group of racks 8 are fixedly connected to the front and rear of the upper middle part of the bottom frame 1; a support sleeve 5 is fixedly connected to the right middle part of the press machine 4; A group of rotating telescopic rods 6 are fixedly connected to the front and rear parts on the right; two groups of baffle plates 7 are fixedly connected to the right ends of the two groups of rotating telescopic rods 6; the uppe...

Embodiment 2

[0051] according to figure 1 with Figure 14-15 As shown, an assembly unit is also included, and the assembly unit includes a third support member 401, a third electric slide rail 402, a sixth electric slide block 403, a connecting plate 404, a second electric actuator 405, a first support plate 406, The first clamping piece 407, the elastic piece 408, the second supporting plate 409 and the second clamping piece 4010; a set of third supporting pieces 401 are fixedly connected to the front and rear of the upper middle left part of the chassis 1; two sets of third supporting pieces 401 A set of third electric slide rails 402 is fixedly connected to the upper top; a sixth electric slider 403 is slidably connected to the bottom of the two sets of third electric slide rails 402; a connecting plate 404 is fixedly connected between the two sets of sixth electric slides 403; The middle part below the connection plate 404 is fixedly connected with the second electric actuator 405; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com