Measuring method of rolling mill rigidity difference

A rolling mill stiffness and difference measurement technology, which is applied in the rolling mill stiffness difference measurement and on-line measurement of rolling mills, can solve problems such as errors and false alarms regardless of measurement, and achieve the effect of improving functional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

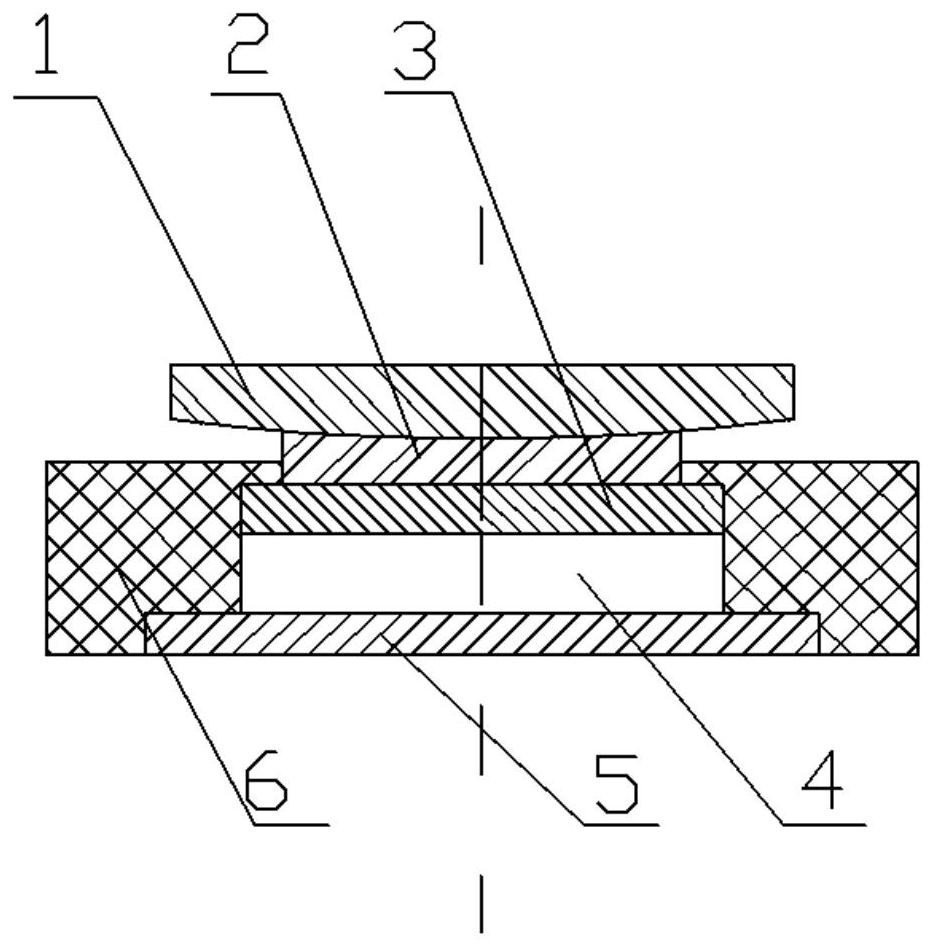

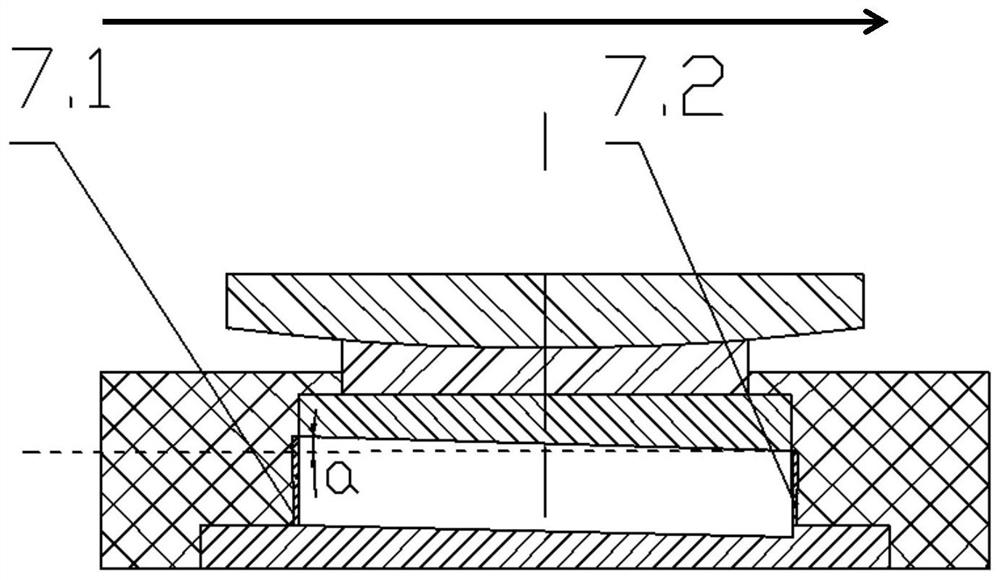

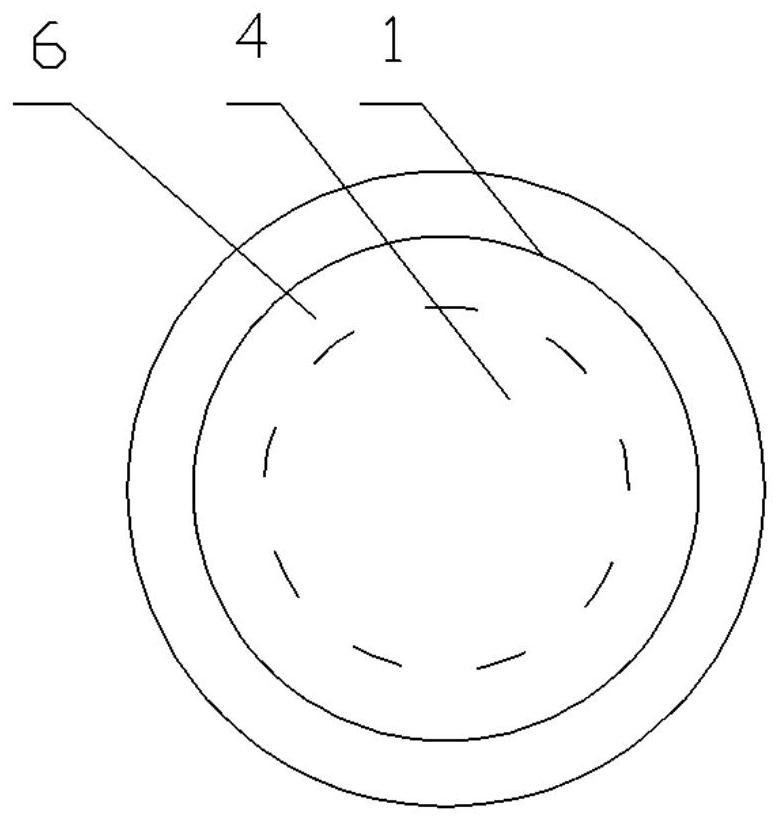

[0020] Such as figure 1 The unit shown is installed under the chocks of the lower back-up rolls of the rolling mill. The pressure measuring head 4 is installed in the mounting frame 6, the pressure measuring head 4 is a cylinder, and the mounting frame 6 is an inner hollow cylinder such as figure 1 shown. An upper pressure equalizing plate 3 is arranged on the pressure measuring head 4, and a lower equalizing pressure plate 5 is arranged below the pressure measuring head. A concave arc-shaped block 2 is arranged on the upper pressure equalizing plate 3, and the effect of the convex arc-shaped block 1 is that after the current supporting roller deviates, after the offset force is canceled, the lower supporting roller can self-return. Such as figure 2 The direction indicated by the arrow is the rolling direction, and a piezoelectric induction sheet 7.1 is installed in the direction of the inlet side, and a pressure induction sheet 7.2 is also installed in the direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com