Automatic scissor foot assembling device

An automatic assembly and scissor foot technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low yield rate, failure of scissor foot assembly, installation shaft pressure break, etc., to improve the yield rate and facilitate follow-up. The effect of reclaiming and placing materials is stable and accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

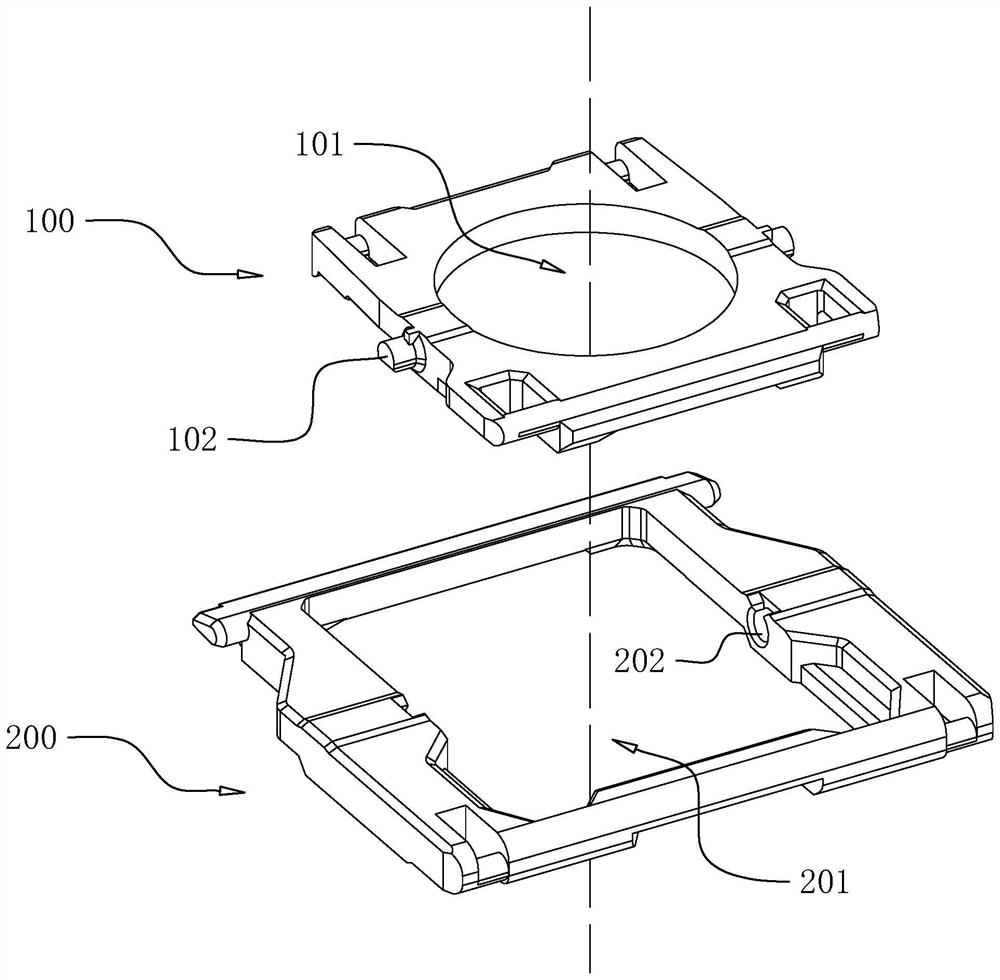

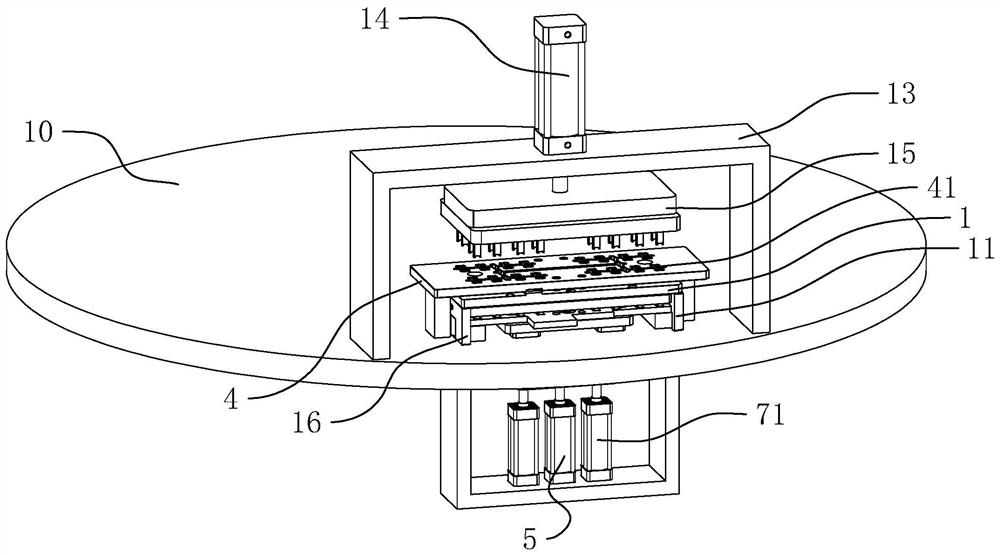

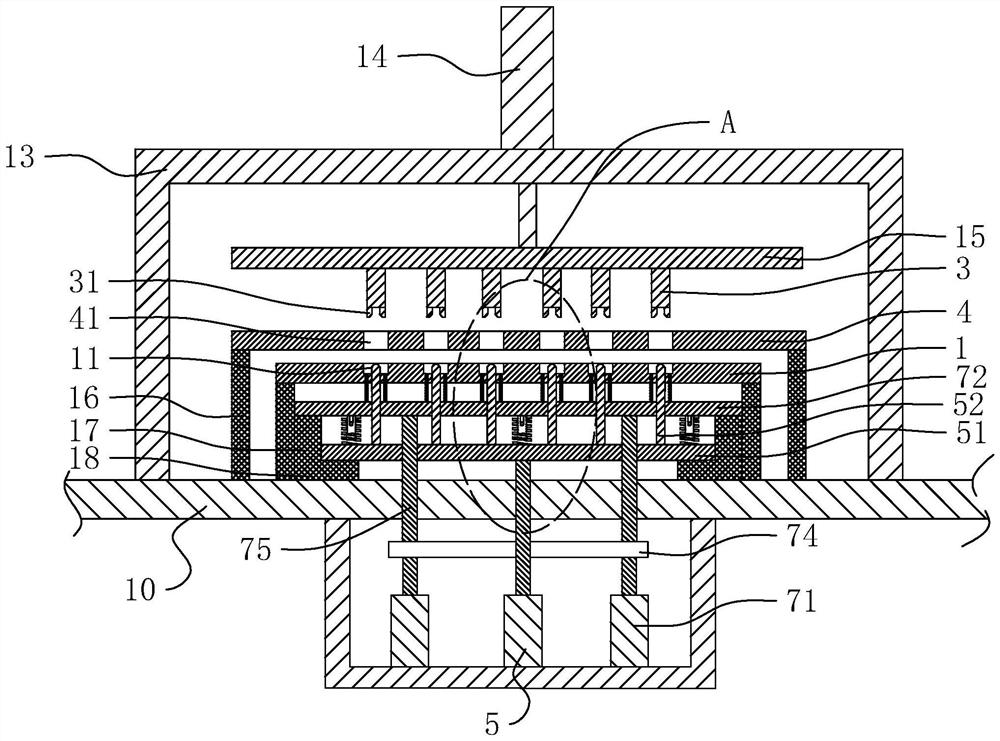

[0041] The following is attached Figure 2-6 The application is described in further detail.

[0042] refer to figure 2 , is an automatic assembly device for scissor feet disclosed in the embodiment of the present application. The scissor foot automatic assembly device is set on a circular workbench 10 , and the scissor foot automatic assembly device occupies one of the workbench 10 stations.

[0043] refer to figure 2 and image 3 , the upper surface of the workbench 10 is provided with an extruding assembly for extruding the inner shear 100 into the outer shear 200: including an inverted C-shaped fixed frame 13, and a downward pressure cylinder 14 is vertically provided at the center of the top surface of the fixed frame 13 , the piston rod of the downward pressure cylinder 14 runs through the top surface of the fixed frame 13 and is arranged downwards, the bottom of the downward pressure cylinder 14 piston rods is horizontally provided with a lower pressure plate 15, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com