Convection tube

A convection tube and a corresponding technology, applied in the field of convection tubes, can solve the problems of complex process, difficult processing and high cost, and achieve the effects of convenient processing, simple structure and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

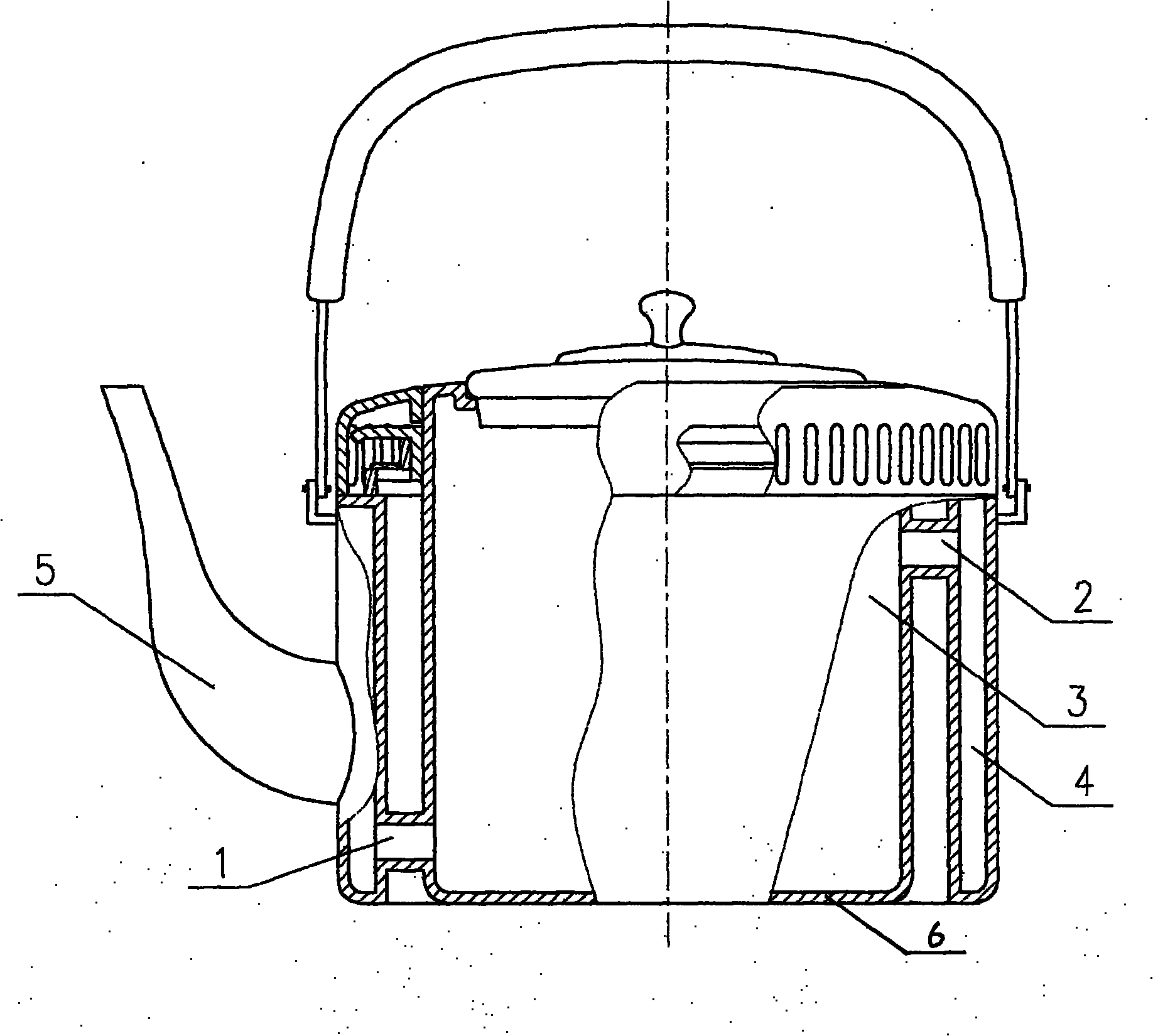

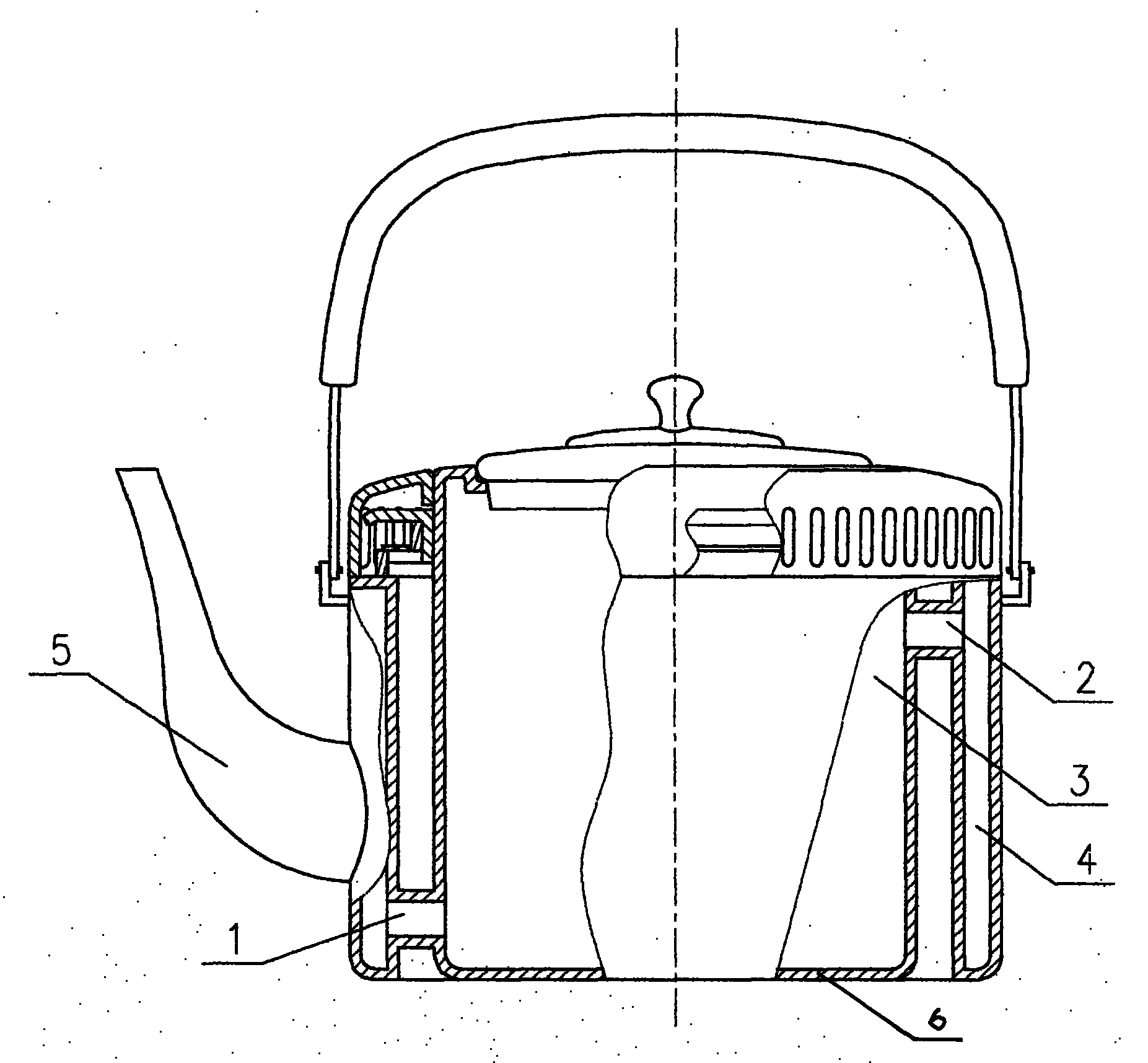

[0013] From figure 1 It can be seen that the convection tube of the energy-saving kettle connects the inner pot 3 and the outer pot 4, the inner pot 3 includes the inner pot bottom 6, and there are two convection tubes, which are respectively convection tube 1 and convection tube 2, and the distance between convection tube 1 and convection tube 2 is The height at the bottom of the inner pot 6 has a height difference.

[0014] The convection tube 1, the convection tube 2 have a height difference from the height of the inner kettle bottom 6, that is, the distances between the convection tube 1, the convection tube 2 and the inner kettle bottom 6 are not equal. Water has the characteristics of thermal expansion and cold contraction, high-temperature water with light specific gravity and low specific gravity, floating upward, and low-temperature water with large specific gravity and heavy specific gravity to sink. When heating, there is a temperature difference between the water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com