Inserted type locking and buckling floor

A plug-in, floor technology, applied in the direction of floors, buildings, coatings, etc., can solve problems such as deterioration of coordination, damage to a single floor, and impact on service life, achieving low manufacturing costs, simple structure, and extended service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

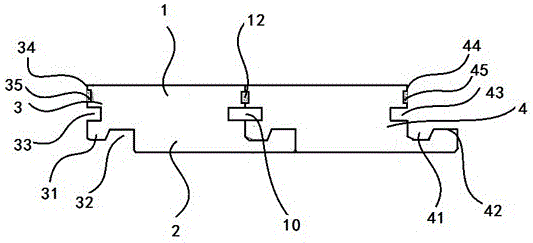

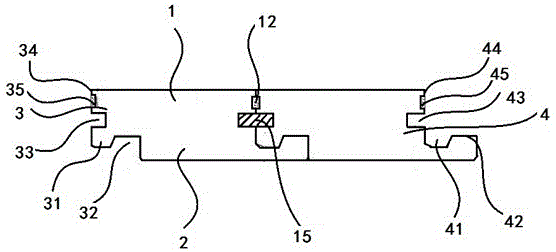

[0024] Such as Figure 1-2As shown, the plug-in locking floor in this embodiment includes a plurality of identical floor units, and the floor units include: a generally flat first surface 1, and a second surface opposite to the first surface 1 surface 2; a first side end 3, and a second side end 4 opposite to the first side end 3, and each side end extends respectively from between said first and second surfaces; said first side end 3 has a downwardly protruding male tenon 31 and a male card groove 32 adjacent to the male tenon 31; at the second side end 4 there is an upwardly protruding female tenon 41 and a female card groove adjacent to the female tenon 41 42. The male tenon 31 and the male card groove 32 of the first side end 3 are engaged with the female card groove 41 and the female tenon 42 of the second side end 4 of the adjacent floor unit respectively, and form at least a partially contacted contact surface; Wherein, the first side end 3 is located above the male te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com