Online four-open-plate device of float glass production line

A technology of float glass and production line, which is applied in the direction of steam engine installation, transportation and packaging, loading/unloading, etc. It can solve the problems of glass sticking to the table and increase labor intensity, etc., and achieve the effect of saving energy and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

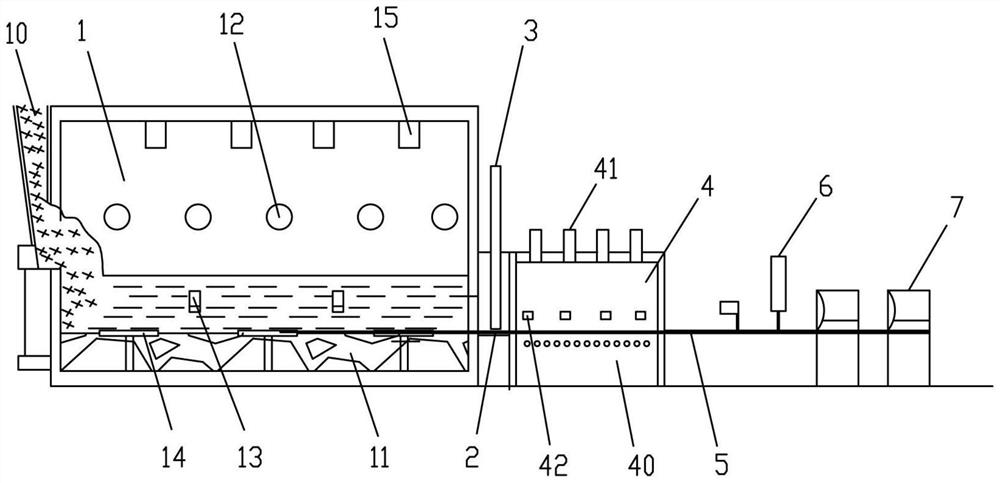

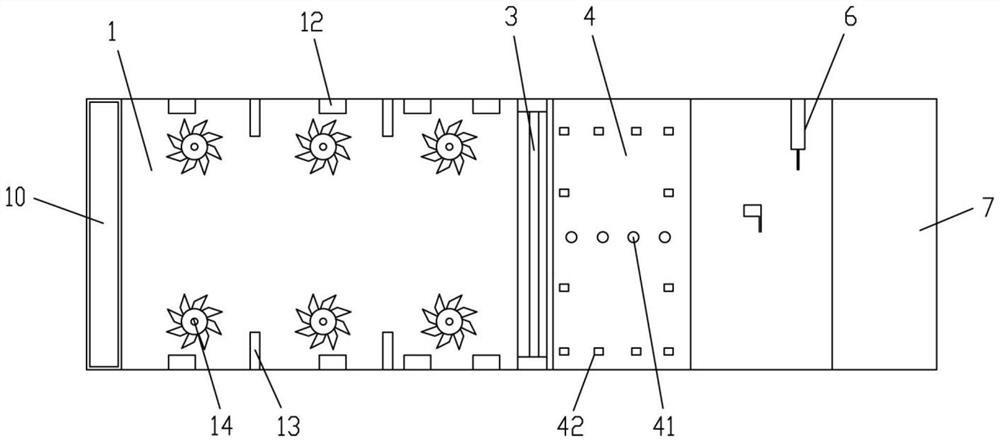

[0030] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

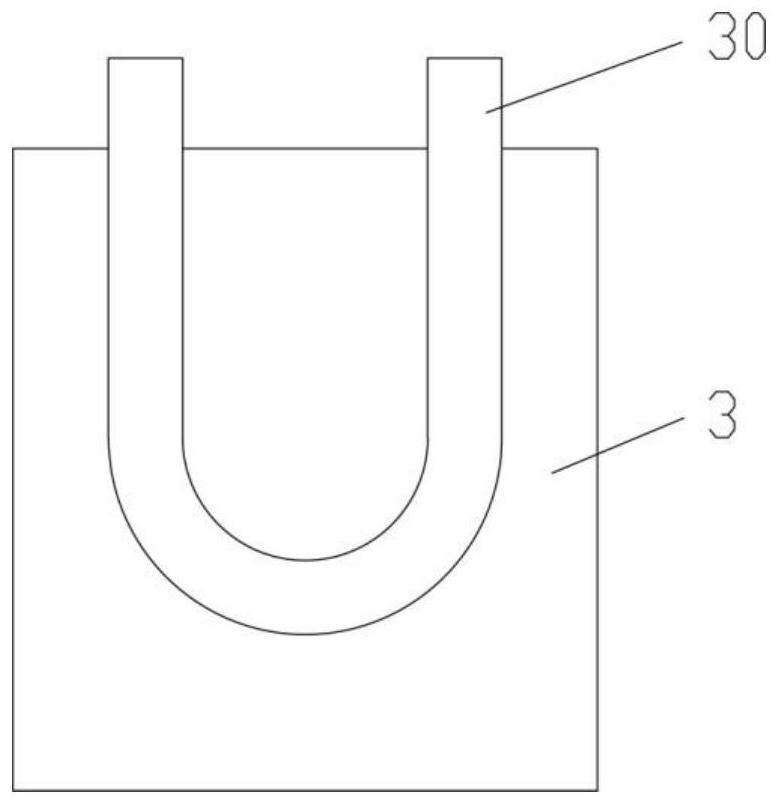

[0031] Such as Figure 1 to Figure 5 As shown, an online four-opening device for a float glass production line according to the present invention includes a melting furnace 1, an annealing furnace 4, a cutting device 6 and a boxing device 7, and a feeding port 10 is provided on the melting furnace 1 for use in Put tin and quartz sand into the melting furnace 1 through the feed port 10, and after the tin passes through the high temperature in the melting furnace 1, it will form a tin liquid 11 on the bottom for the lining, which can effectively prevent the bottom of the glass liquid surface from being uneven , the lower part of the inner side wall of the melting furnace 1 is provided with a plurality of blocking flags 13, which can play the role of regulating flow in the melting furnace, and are provided with a plurality of thumbwheels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com