Rigid-flexible combined contact net system for non-upper cover field section

A rigid-flexible combination and catenary technology, applied in the field of rail transit, can solve problems such as emergency safety risks, traffic difficulties, and high requirements for civil structure installation, and achieve the effect of simplifying electrical connections and preventing malfunctions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

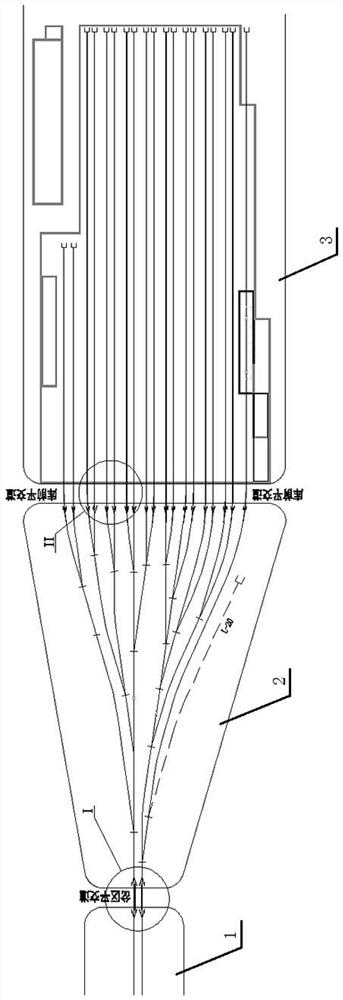

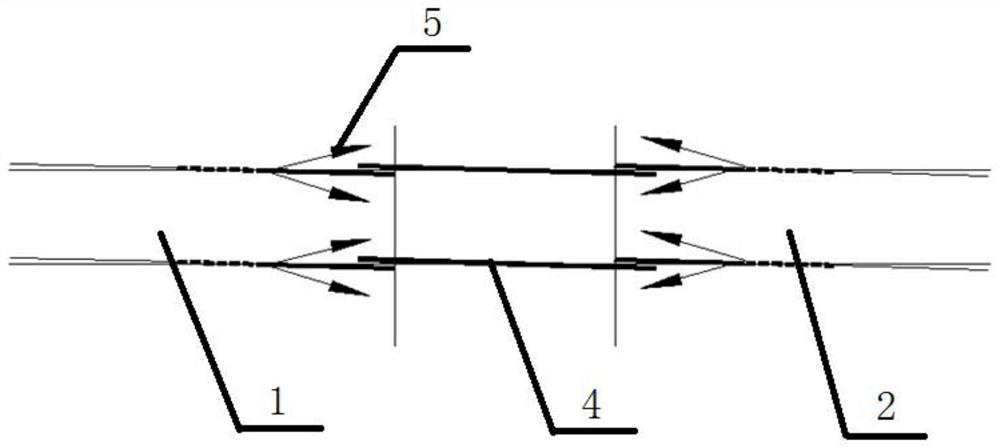

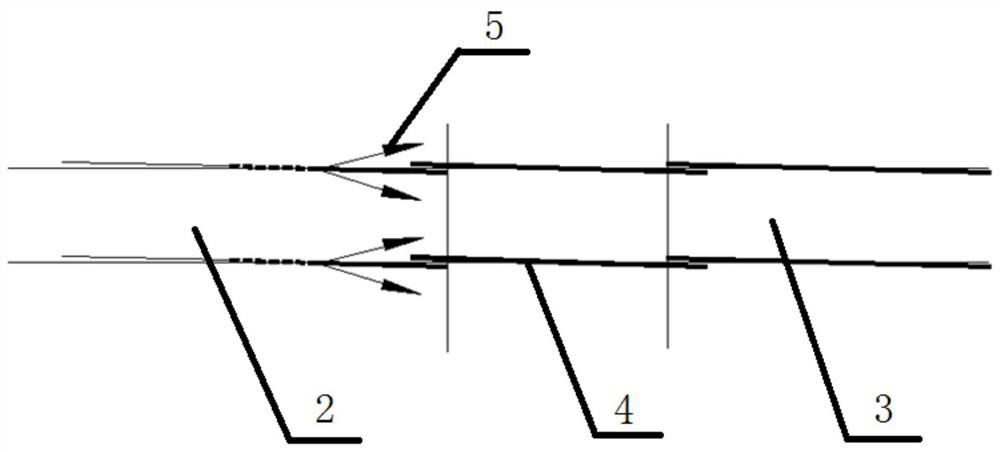

[0029] Embodiments of the present invention provide a rigid-flexible catenary system for a non-covering field segment, such as figure 1 As shown, the access line 1 and the throat area 2 of the field section are provided with a flexible suspension catenary, a rigid suspension catenary is provided in the garage 3, and a movable type is provided at the level crossing 1 of the fork area between the access line 1 and the throat area 2. The catenary 4, the movable catenary 4 is also set at the level crossing II in front of the warehouse between the throat area 2 and the garage 3. The movable catenary 4 can disconnect the catenary in case of emergency, so as to release the restriction on the traffic height of the vehicle by the catenary.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com