Biaxial tensile mechanical property testing device and method for multi-configuration test piece

A technology of biaxial stretching and testing equipment, applied in the direction of measuring equipment, applying stable tension/pressure to test material strength, scientific instruments, etc., can solve the problem of not being able to meet the research requirements of mechanical properties of materials, not equipped with temperature boxes and temperature control devices , low loading rate and other issues, to achieve the effect of satisfying large-scale repetitive tests, simple connection method, and short connection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

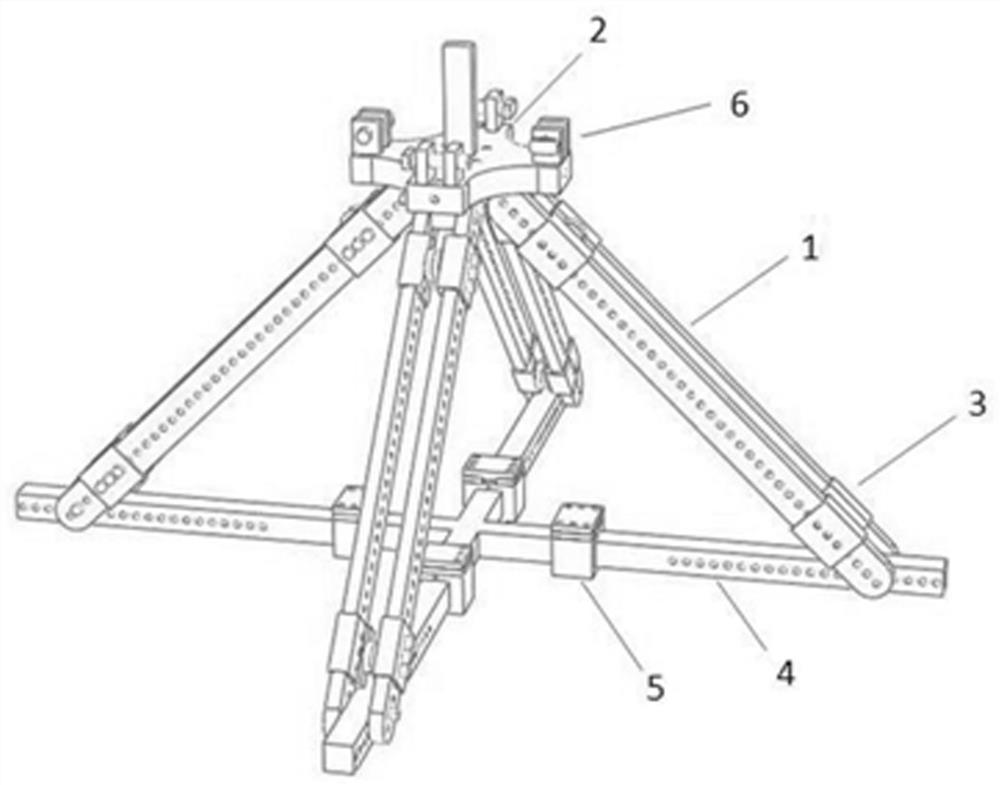

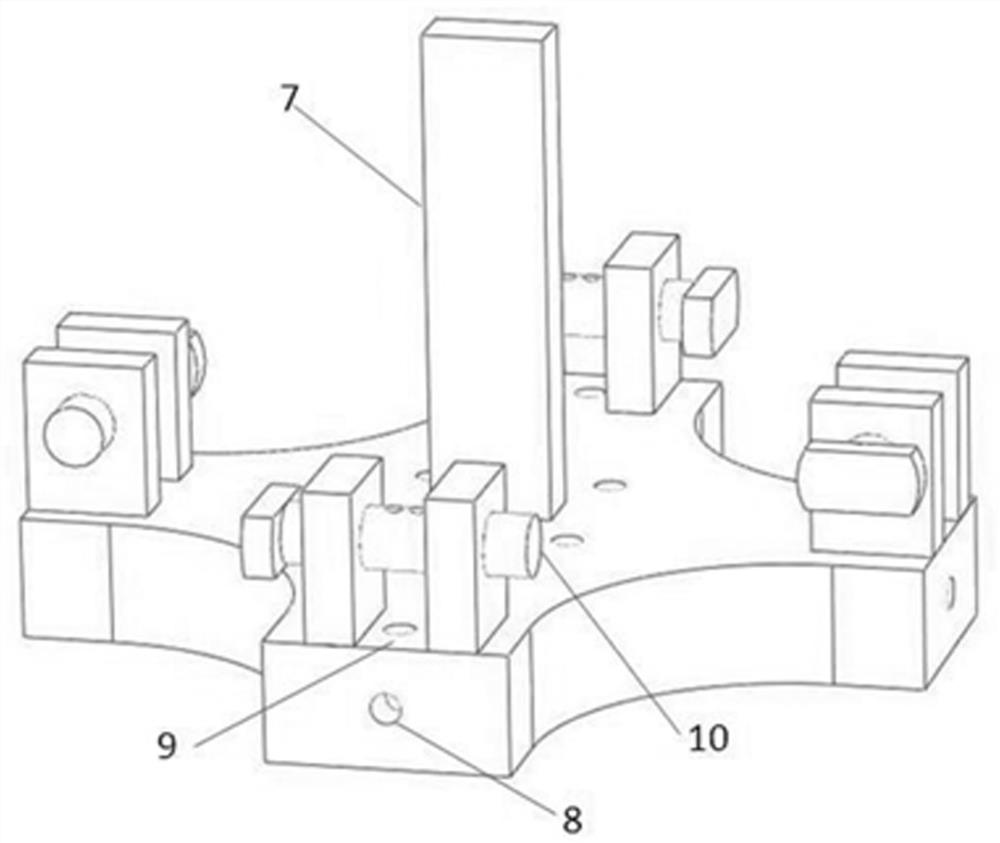

[0076] The present invention is a test device for biaxial tensile mechanical properties of a multi-configuration test piece, comprising an upper fixture and a lower fixture connected to the testing machine and arranged correspondingly up and down, the upper fixture includes an upper fixture body 2 in an orthogonal cross configuration , the four extension arms of the upper clamp body 2 are the upper support arms, the centerlines of the four upper support arms are located in the same plane, and the extension lengths are equal, and the center of the upper clamp body 2 is fixedly provided for connecting with the testing machine. The upper clamping part of the upper clamping part protrudes toward the direction away from the lower clamp;

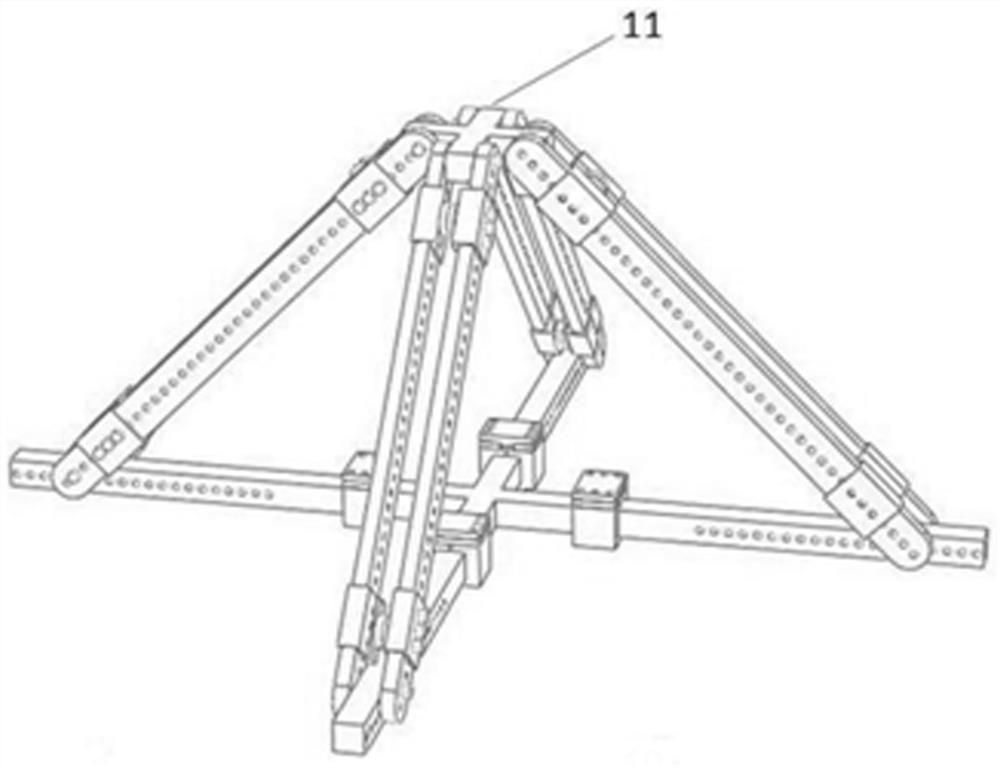

[0077] The lower clamp includes a cross-shaped base 4 and a connecting piece 11. The size of the base 4 is larger than that of the entire upper clamp, which is convenient for operation and control, and has a small tensile moment. The four extensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com