Sand cleaning and part-taking device of 3D printer

A 3D printer and pick-up device technology, applied in cleaning methods and appliances, cleaning methods using gas flow, chemical instruments and methods, etc., can solve the problems of manual cleaning and the sliding part is easy to get stuck in sand, etc., to achieve Elastic locking, to achieve the effect of shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

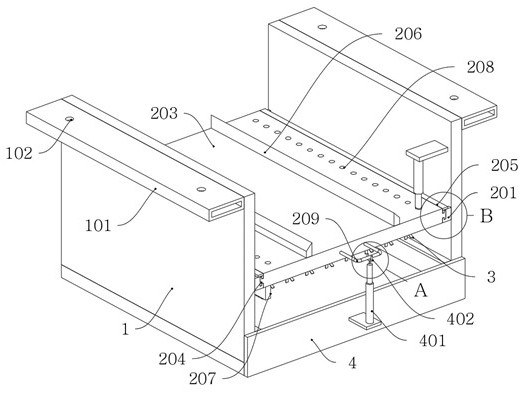

[0056] as attached figure 1 to attach Figure 8 Shown:

[0057] The present invention provides a 3D printer sand removal device, including a housing 1;

[0058] The housing 1 is a concave structure;

[0059] Placement structure 2, and placement structure 2 is installed on shell 1;

[0060] The cleaning structure 3 is installed on the casing 1 .

[0061] Reference as figure 1 , housing 1 includes:

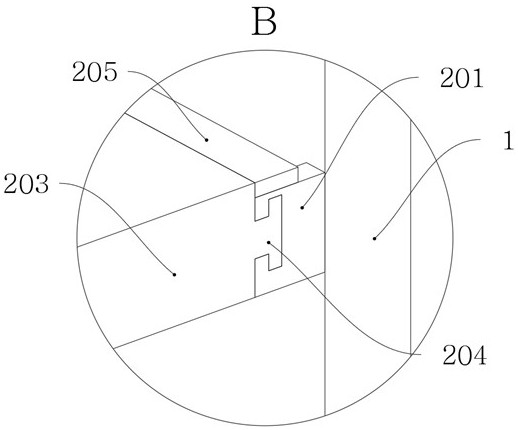

[0062] There are two fixed seats 101, and there are two fixed seats 101, and the two fixed seats 101 are welded symmetrically on the housing 1; each fixed seat 101 is symmetrically provided with two fixed holes 102, and the two fixed seats 101 The cross-sections are all back-shaped structures, so that the elastic anti-loosening of the fixing bolts can be realized;

[0063] A drawer 4 is installed on the casing 1 .

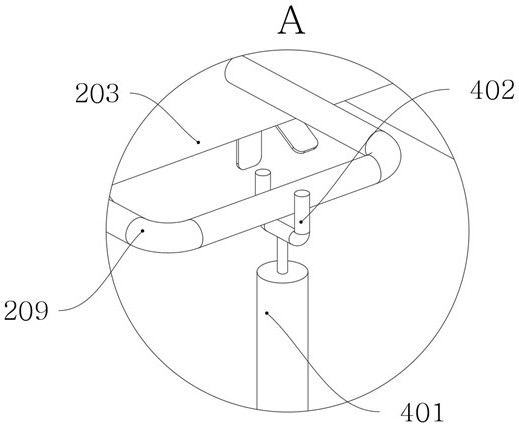

[0064] Reference as Figure 7 with 8 , the placement structure 2 consists of:

[0065] There are two sliding seats 201, and there are two sliding seats 201, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com