Tunnel type dust remover for automatic dust removal of shoe sole

An automatic dust removal, tunnel-type technology, applied in the direction of cleaning methods using gas flow, smoke and dust removal, cleaning methods and utensils, etc., can solve pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described below with reference to the accompanying drawings.

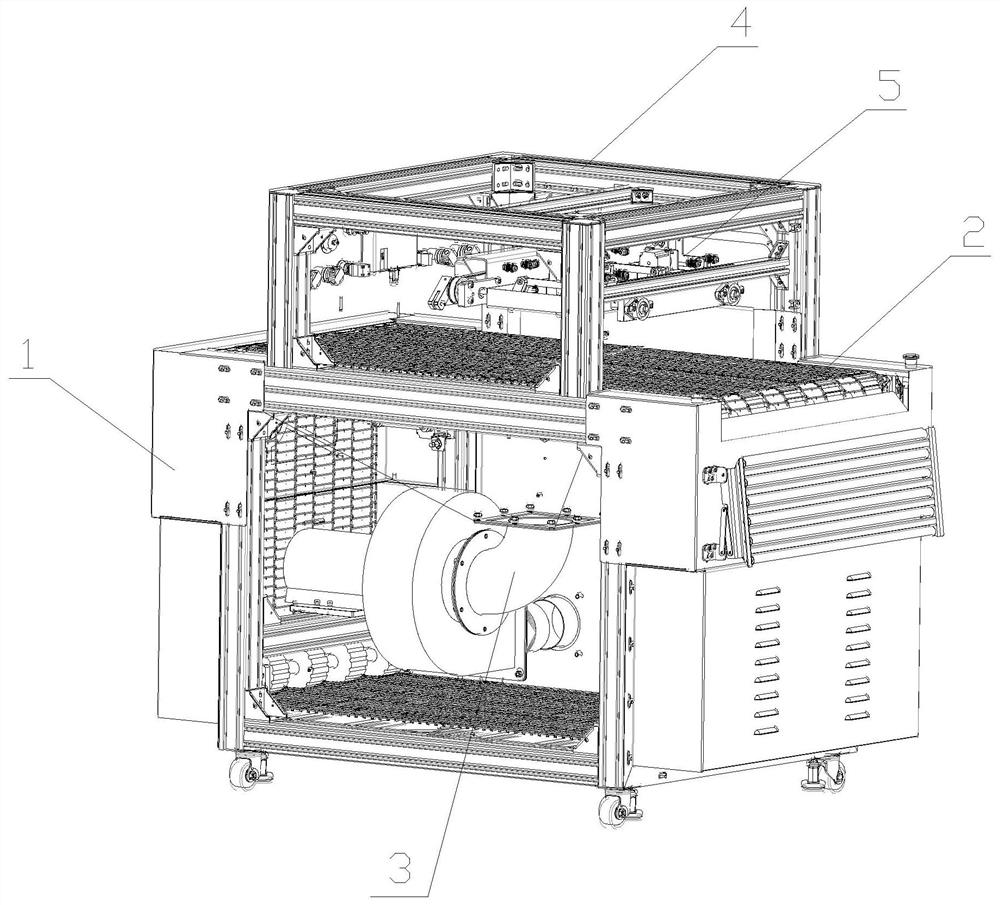

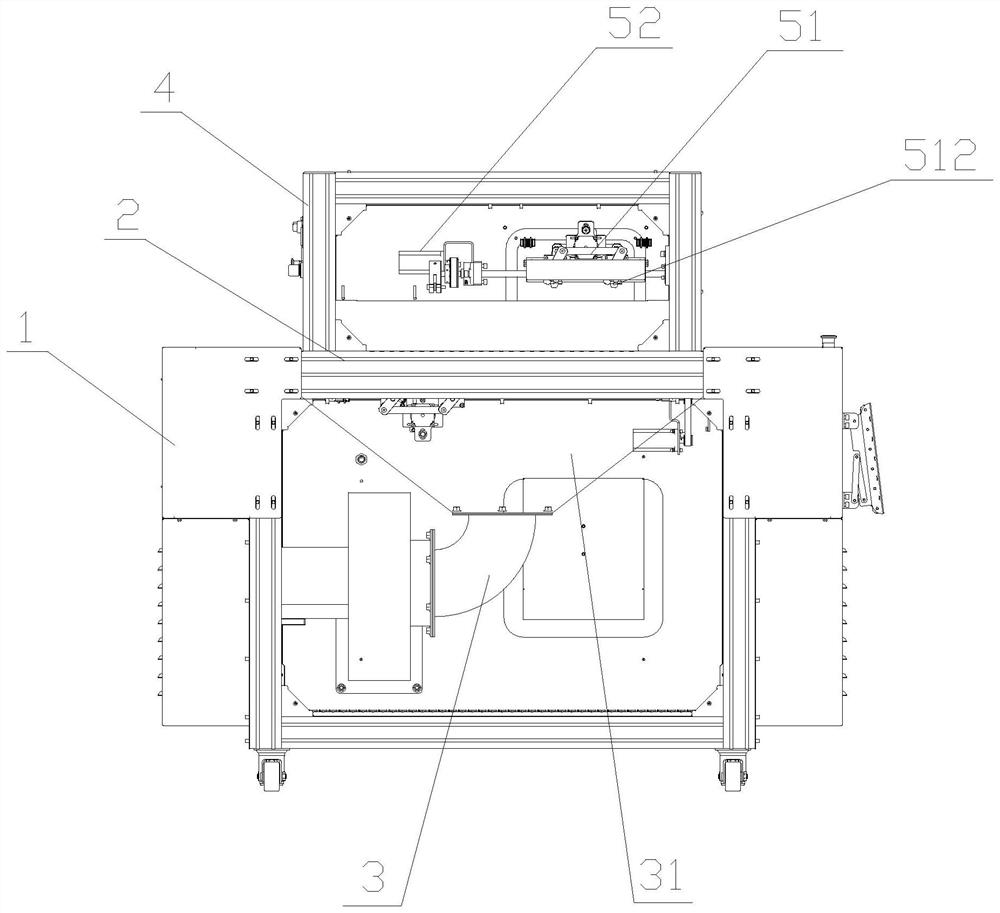

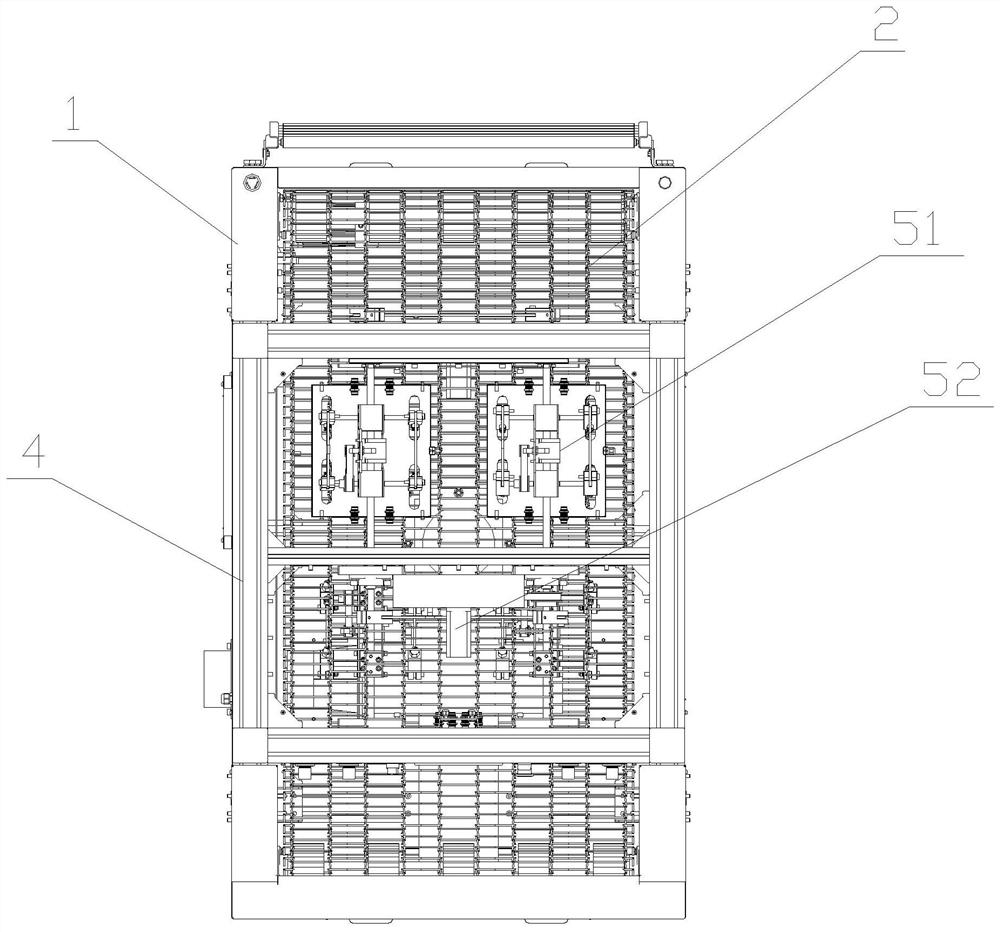

[0021] Such as Figure 1 to Figure 4 As shown, a tunnel-type dust collector for automatic dust removal of shoe soles includes a frame body 1, and an endless conveyor belt 2 is arranged around the frame body 1, and the machine located below the conveying surface of the endless conveyor belt 2 The frame body 1 is equipped with a dust adsorption machine 3, and the frame body above the conveying surface of the endless conveyor belt 2 is provided with a dust removal tunnel cavity 4, and the endless conveyor belt 2 is transported through the dust removal tunnel cavity 4, so that The dust-removing tunnel cavity 4 is provided with two air supply devices 5 in turn along the conveying direction of the endless conveyor belt 2, which are respectively an air-supply device arranged at the bottom of the dust-removing tunnel cavity 4 and an air-sup...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap