Single-ball type air floatation pulley device combining air floatation ball bearing and air floatation plane thrust bearing

A technology of plane thrust bearings and ball bearings, which is applied in the field of aerospace, can solve the problems that the accuracy of zero-gravity simulation cannot be improved, and achieve the effects of reducing friction, avoiding body axis tilt, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

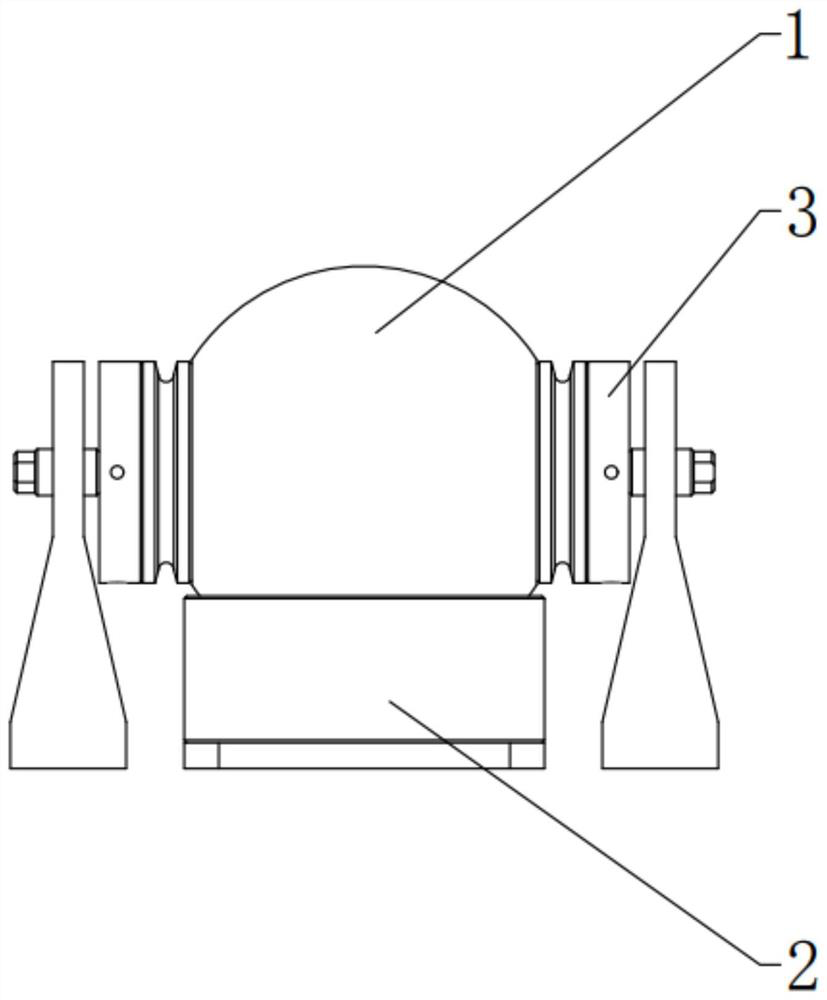

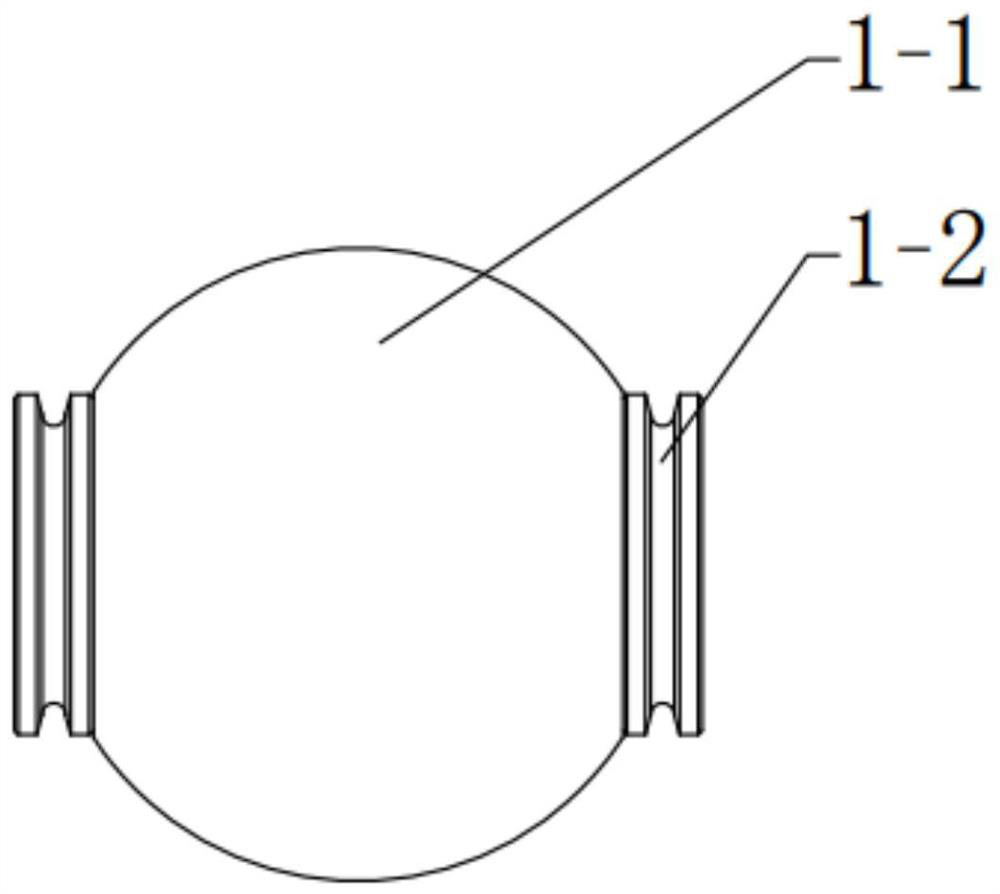

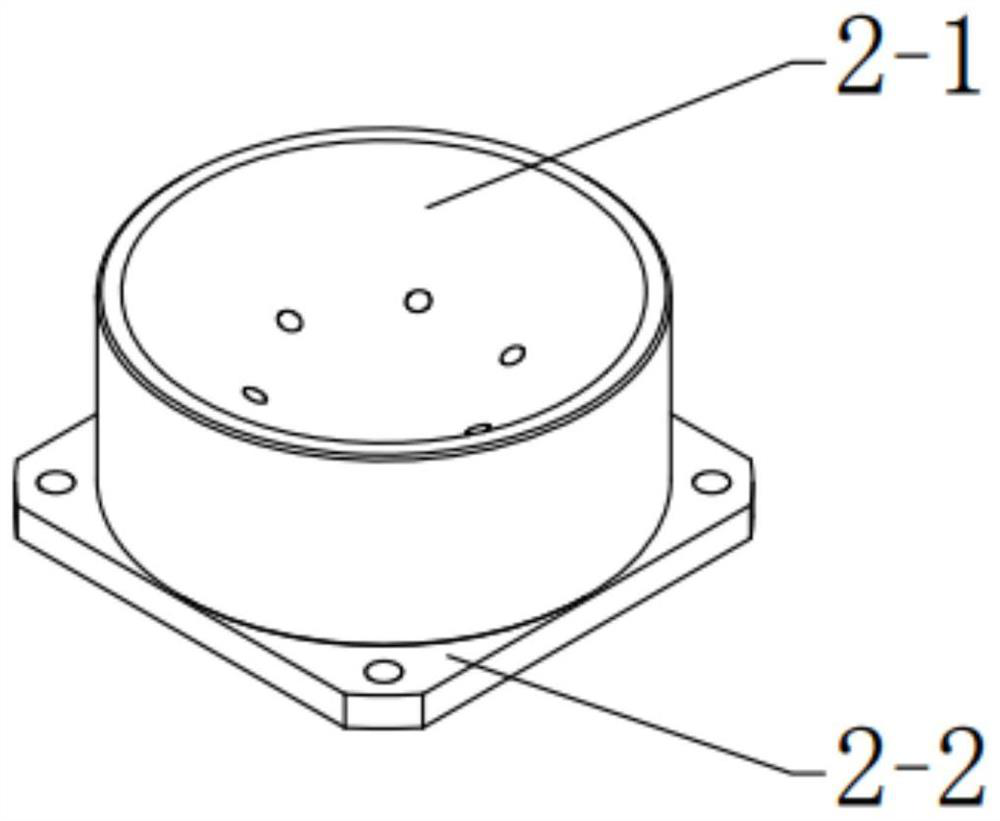

[0018] Specific implementation mode one: the following combination Figure 1 to Figure 4 This embodiment is described. A single-ball air-bearing pulley device combined with an air-floating ball bearing and an air-floating plane thrust bearing in this embodiment includes an air-floating rotary ball assembly 1, an air-floating rotary ball-and-socket assembly 2 and a rotary Side air bearing thrust support assembly 3;

[0019] The air-floating revolving ball assembly 1 is located on the air-floating revolving ball-and-socket assembly 2, and both sides of the air-floating revolving ball assembly 1 are clamped and supported by the air-floating thrust support assembly 3 on the revolving side.

[0020] see figure 1 Shown is the single-ball type air-floating pulley device described in this embodiment. The air-floating rotary ball assembly 1 and the air-floating rotary ball-and-socket assembly 2 are connected in an air-floating manner, and the air-floating rotary ball assembly 1 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com